Product Features

JNH series -- Sand casting machining with up and down sand shooting

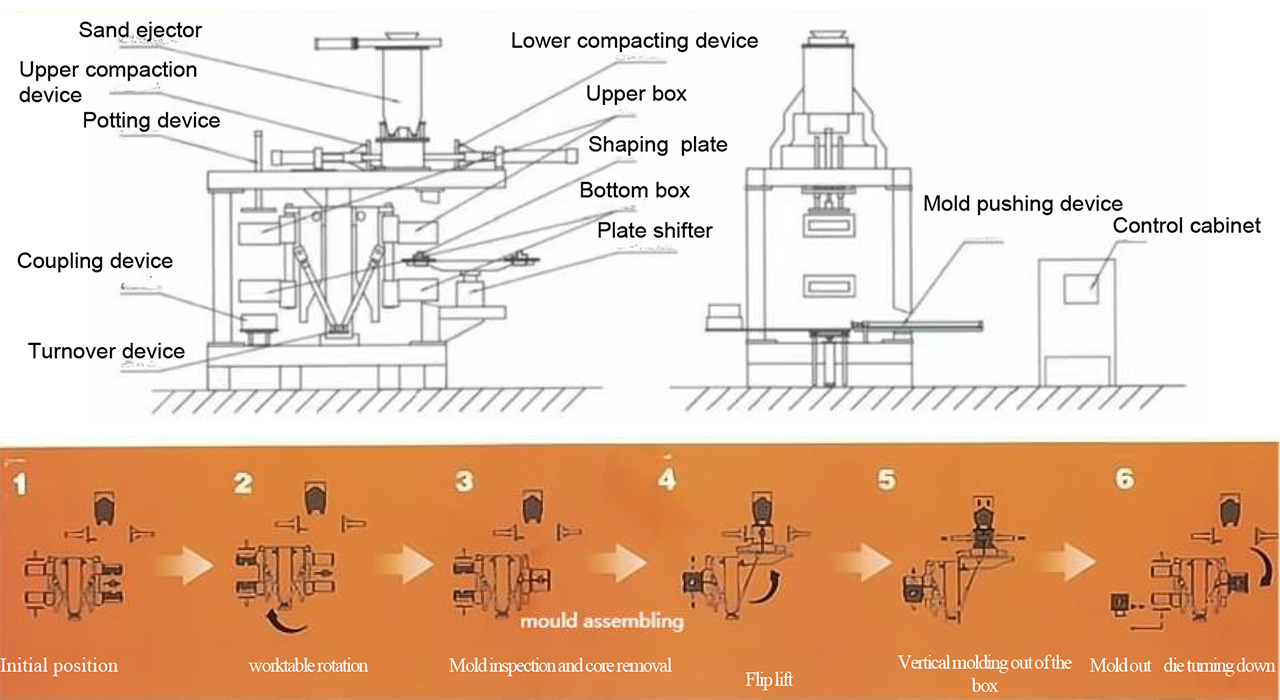

The JNH Top and Bottom Sand Shooting Molding Machine is a servo-driven, high-pressure automatic molding solution designed to deliver superior mold quality for a wide range of casting requirements. Incorporating a top-and-bottom blow system, this machined sand casting achieves uniform sand compaction from both directions, effectively eliminating shadow effects and improving the surface finish of complex castings.

1. High-Speed Molding: The Sand casting machining boasts a high-speed molding capability of up to 26 seconds per mold, without the need for additional core setting time, significantly increasing production efficiency.

2. Up and Down Sand Shooting Technology: The machined sand casting equipped with vertical sand shooting technology, it is best suited for deep-pocket patterns to effectively eliminate shadowing, ensuring the quality of the castings.

3. Squeeze Pressure Balance Control: The squeeze pressure balance control ensures stable molding and prevents pattern distortion, enhancing the precision of the castings.

4. Mold Height Feedback Control: The mold height feedback control system reduces sand consumption and compensates for compaction variations, optimizing sand usage.

5. User-Friendly Operation: The machining sand castings features a touch screen panel for easy operation, improving user-friendliness and reducing the difficulty of operation.

Available in single- or double-station configurations, the JNH series (automatic sand casting machine) features a rigid four-column structure for enhanced stability and an intuitive human-machine interface (HMI) for easy operation and process control. Key molding parameters such as extrusion pressure, mold height, and forming speed are fully adjustable to meet varying production needs.

By combining high-pressure hydraulic compaction, servo-controlled sand shooting, and automated mold ejection, the JNH series (foundry green sand casting machine) offers a reliable, efficient, and operator-safe molding process ideal for high-volume, precision casting environments.

1. Top and Bottom Sand Shooting System – Dual-directional sand blowing of the Sand casting machining ensures uniform filling and compactness throughout the mold, enhancing mold surface hardness and casting precision.

2. High-Pressure Hydraulic Compaction – Adjustable hydraulic pressure enables fine-tuned control over mold density, ensuring consistent quality across castings of varying complexity.

3. Servo-Controlled Operation – Advanced servo systems provide precise control over shooting and compaction processes, optimizing performance and energy efficiency.

4. Adjustable Mold Height and Squeeze Speed – Mold height and forming speed can be modified to accommodate a variety of casting specifications while minimizing sand usage.

5. Four-Column Rigid Frame – The machine’s robust structure ensures high precision and stability during high-speed operation.

6. User-Friendly HMI Interface – Centralized touchscreen controls allow for parameter setting, real-time monitoring, troubleshooting, and maintenance support.

7. Automated Blowout and Mold Ejection System – Streamlined hydraulic systems automate mold release and transition to the pouring line, improving production flow.

8. Lubricated Guide Columns – Integrated lubrication reduces wear and maintains alignment accuracy, extending machine lifespan.

9. Operator Safety Features – The control panel is positioned outside the machine’s operating zone and equipped with safety light guards to protect personnel during operation.

Product Parameter

JNH series -- Sand casting machining with up and down sand shooting

| Model | Mold Size | Mold Height from (Cope) | Mold Height to (Drag) | Average Maximum Mold Rate (without Core setting) | Molding System |

|---|---|---|---|---|---|

| JNH3545 | (300~380)*(400~480)mm | 130~250mm | 130~250mm | 26 seconds/mold (without core-setting time) | Edge Blow + Squeeze |

| JNH4555 | (400~480)*(500~580)mm | 130~250mm | 130~250mm | 26 seconds/mold (without core-setting time) | Edge Blow + Squeeze |

JNH5565 | (500~580)*(600~680)mm | 130~250mm | 130~250mm | 26 seconds/mold (without core-setting time) | Edge Blow + Squeeze |

JNH6575 | (600~680)*(700~780)m | 130~250mm | 130~250mm | 26 seconds/mold (without core-setting time) | Edge Blow + Squeeze |

JNH7585 | (700~780)*(800~880)mm | 130~250mm | 130~250mm | 26 seconds/mold (without core-setting time) | Edge Blow + Squeeze |

Company Profile

JUNENG Machinery Co., Ltd., founded in 2011, is a prominent player in the global machined sand casting industry. As a subsidiary of Shengda Machinery Co., Ltd., JUNENG specializes in the development and production of cutting-edge machining sand castings,vertical automatic sand casting machine, and complete casting assembly lines. With a strong focus on innovation, JUNENG integrates advanced technology, high efficiency, and reliability into every product.

About Us

Founded on a foundation of excellence, JUNENG is dedicated to providing intelligent and cost-effective solutions to the casting industry. We are a high-tech research and development enterprise committed to advancing the field of foundry green sand casting machine . Our comprehensive range of products includes automated customized ductile iron sand casting machine and fully integrated casting lines designed to meet the needs of small to medium-sized casting operations.

Among our flagship products, Our JN-FBO Vertical Sand casting machining and Horizontal Parting delivers high precision and efficiency for advanced casting applications. The JN-AMF Double Station Vertical machined sand casting and Horizontal Parting enhances productivity with its dual-station design, delivering high-precision results. The JNH Top and Bottom Sand Shooting equipment used in sand casting offers a versatile and cost-effective solution for various molding applications. And the JNP Horizontal machining sand castings needed for sand casting provides an economical option for simpler casting needs.

Through continuous technological advancements and a deep commitment to quality, we ensure that our foundry green sand casting machine are among the most reliable and efficient on the market. Our systems help businesses reduce labor costs, increase operational efficiency, and improve overall casting quality, making us a trusted partner for companies worldwide.

Our Vision & Values

At JUNENG, our mission is clear: to lead the global customized ductile iron sand casting machine market through a relentless focus on quality, innovation, and customer satisfaction. We adhere to the core principles of “Market-driven, Quality-focused” in everything we do. By leveraging the latest technology, we consistently push the boundaries of what is possible in sand casting machining automation. We aim to provide our customers with not only cutting-edge machined sand casting but also end-to-end solutions that enhance their production capabilities.

Global Reach & Industry Leadership

With a state-of-the-art manufacturing facility spanning over 10,000 square meters, JUNENG has firmly established itself as an industry leader. Our machining sand castings are trusted by customers in over 20 countries, including the United States, Brazil, India, Russia, and Vietnam. Our global reach is further supported by a network of authorized agents and sales offices, ensuring that we can deliver localized service and technical support to all our international clients.

In addition to providing high-quality automatic sand casting machine , JUNENG maintains a dedicated after-sales service system designed to offer timely technical support and assistance. Whether through direct service centers or our authorized partners, we are committed to creating lasting value for our customers and ensuring the seamless operation of their foundry green sand casting machine.

Commitment to Innovation

As the casting industry evolves, so does JUNENG. We continuously monitor market trends and customer needs, adapting our solutions to meet the challenges of modern manufacturing. With strategic investments in research and development about sand customized ductile iron sand casting machine, we are poised to remain at the forefront of industry advancements, providing customers with state-of-the-art sand casting machining that improve performance, reliability, and cost-efficiency.