Product Features

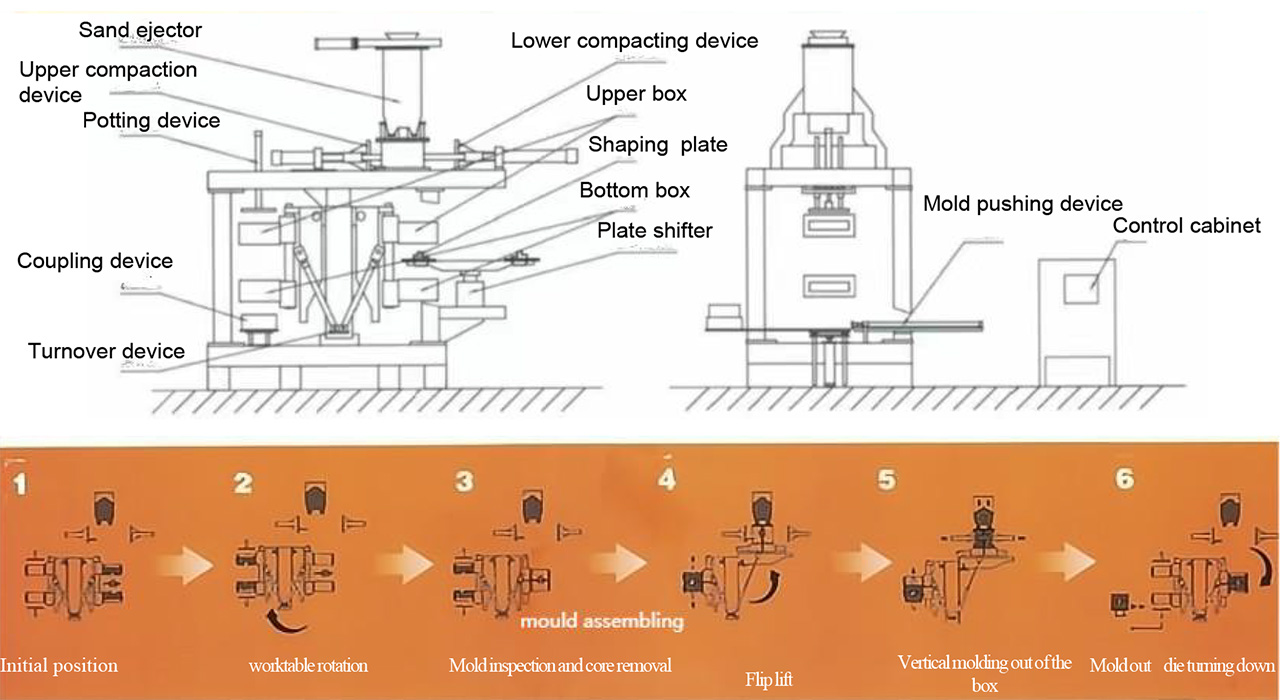

The JN-AMF Foundry Molding Line with Double Workstation Vertical Sand Shooting and Horizontal Parting combines the benefits of vertical sand shooting, vertical molding, and horizontal parting into a single, efficient system. Designed with dual workstations, it enhances productivity by allowing alternating operations between two independent sets of sandboxes.

In operation, one set of sandboxes rotates 90 degrees upward to position beneath the sand shooting bucket. Sand is then shot vertically from above using compressed air, followed by hydraulic compaction to ensure mold integrity. After compaction, the sandbox returns to its horizontal position, and the mold is smoothly ejected onto the pouring cooling line. While one mold is being processed, the second set of sandboxes is prepared, allowing for continuous, alternating cycles that significantly boost production efficiency.

1. Dual Workstation Design – Alternating operations between two independent sets of sandboxes enable continuous molding cycles, enhancing productivity.

2. Vertical Sand Shooting– The 90-degree rotation positions the sandbox for vertical sand shooting from above, ensuring optimal sand filling and mold compaction.

3. Horizontal Parting and Mold Ejection – Post-compaction, the sandbox returns to a horizontal position, facilitating smooth mold ejection and preparation for pouring.

4. Adjustable Mold Height and Sand Volume – Operators can fine-tune mold height and sand volume through the human-machine interface, optimizing material usage and reducing production costs.

5. Precise Compaction Control – The hydraulic system allows for stepless adjustment of compaction pressure, ensuring consistent mold quality.

6. High Precision in Sandbox Alignment – The system ensures accurate alignment during sandbox closing and opening, maintaining mold integrity.

7. Efficient Mold Changeover – The design facilitates easy mold plate changes, allowing the reuse of existing templates and minimizing downtime.

8. Integrated Fault Detection – The machine features a fault indication system, simplifying troubleshooting and maintenance.

Superior Surface Finish with Precision Molding Technology

The integration of vertical molding with horizontal parting ensures exceptional mold quality and surface finish. The vertical shooting system, operating at 0.4-0.7 MPa pressure, completely fills pattern cavities without voids or weak spots, while the horizontal parting mechanism maintains perfect alignment between cope and drag sections. This combination produces molds with consistent hardness of 92-96 HB and excellent dimensional stability. The system's precision rivals that of specialized moulding sander machine equipment in achieving smooth surface finishes, significantly reducing subsequent cleaning and machining requirements. This results in lower production costs and higher quality castings with minimal rejection rates.

Robust Construction and Smart Factory Integration

Built for 24/7 industrial operation, this sand casting moulding machine features heavy-duty construction with reinforced steel frames, dual hydraulic systems, and wear-resistant components. The dual-station design incorporates energy-saving features such as variable displacement pumps and regenerative circuits that reduce power consumption by 35% compared to conventional machines. As a modern automatic sand moulding machine, it offers comprehensive IoT connectivity for real-time monitoring of production data, maintenance needs, and energy consumption. The enclosed shooting chambers contain sand and dust, while advanced noise reduction technologies maintain operational levels below 75 dB, ensuring a clean and safe working environment.

Foundry Molding Line with Double Workstation Vertical Sand Shooting and Horizontal Parting,From the top of the sand bucket with pressure, pressure drop evenly distributed in the entire sand bucket, sand from the top down into the sand box, sand flow distance is short, so it has the best filling performance, sand pressure gradient is low, the sand in the bucket by the compact strength is small, easy to shoot sand, and not the production of shed and perforation.

The sand deflector is installed in the sand mouth of the sand box to change the direction of the sand flow, effectively control the direction of the sand flow in the process of the sand flow, so that the sand flow avoids the template and refracts into the pussy of the shape, which not only protects the shape, but also powerfully fills the shadow part of the shape!

Product Parameter

JN-AMF Double Workstation Vertical Sand Moulding Machine and Horizontal Parting

| Model | Mold Size | Mold Height from (Cope) | Mold Height to (Drag) | Average Maximum Mold Rate (without Core setting) | Molding System |

|---|---|---|---|---|---|

JN-AMF2 | 16" x 20" | 5" - 8" | 5" - 8" | 200 molds/hour | Aeration Sand Filling + Squeeze |

| 400 mm x 500 mm | 130 mm - 200 mm | 130 mm - 200 mm | 200 molds/hour (Including the 9sec core-setting time) | Aeration Sand Filling + Squeeze | |

JN-AMF3 | 20" X 24" (508 mm x 609.6 mm) | 5" - 8" | 5" - 8" | 200 molds/hour (Including the 9sec core-setting time) | Aeration Sand Filling + Squeeze |

| 500mm x 600mm | 130 mm - 200 mm | 130 mm - 200 mm | 200 molds/hour | Aeration Sand Filling + Squeeze | |

| 550 mm x 650mm | 130 mm - 200 mm | 130 mm - 200 mm | 200 molds/hour | Aeration Sand Filling + Squeeze | |

JN-AMF4 | 24" X 28" (609.6 mm x 711.2 mm) | 180 mm- 250 mm | 180 mm- 250 mm | 170 molds/hour | Aeration Sand Filling + Squeeze |

| 600 mm x 700 mm | 180 mm- 250 mm | 180 mm- 250 mm | 170 molds/hour | Aeration Sand Filling + Squeeze |

JUNENG Machinery ADVANTAGE

JUNENG Machinery Co., Ltd.,

1、15 years of production and design experience in Foundry.

2、Equipment gets the international certification: CE, ISO14001, ISO9001, TUV, BV.

3、Get a government-granted endorsement of trust. ATHI is trustworthy.

4、All designs adopt 3D Design.

5、OEM&ODM factory, High-quality after-sales service.

6、The equipment is environmentally friendly, safe and cost-effective.

7、All adopt general parts, easy to buy and replace.

Our Vision & Values

At JUNENG, our mission is clear: to lead the global types of moulding machine in foundry market through a relentless focus on quality, innovation, and customer satisfaction. We adhere to the core principles of “Market-driven, Quality-focused” in everything we do. By leveraging the latest technology, we consistently push the boundaries of what is possible in foundry molding equipment automation. We aim to provide our customers with not only cutting-edge foundry molding equipments but also end-to-end solutions that enhance their production capabilities.

Global Reach & Industry Leadership

With a state-of-the-art manufacturing facility spanning over 10,000 square meters, JUNENG has firmly established itself as an industry leader. Our foundry molding line are trusted by customers in over 20 countries, including the United States, Brazil, India, Russia, and Vietnam. Our global reach is further supported by a network of authorized agents and sales offices, ensuring that we can deliver localized service and technical support to all our international clients.

In addition to providing high-quality automatic foundry moulding line, JUNENG maintains a dedicated after-sales service system designed to offer timely technical support and assistance. Whether through direct service centers or our authorized partners, we are committed to creating lasting value for our customers and ensuring the seamless operation of their moulding machine foundry.

Our Global Presence

JUNENG’s foundry molding line are highly regarded not only in China but also in key markets around the world. Our automatic foundry moulding line is utilized in industries ranging from automotive and aerospace to industrial manufacturing and construction. We continue to expand our presence globally, with active operations and partnerships in North America, South America, Europe, Southeast Asia, and beyond.

Conclusion

As a leading manufacturer of foundry molding equipment , JUNENG Machinery is dedicated to delivering world-class solutions that meet the evolving needs of the casting industry. With a commitment to quality, innovation, and customer satisfaction, we strive to remain the partner of choice for businesses looking to enhance their production capabilities and stay ahead in a competitive global market.

Our reputation for high-quality products and exceptional customer service has made us a preferred supplier for leading casting companies worldwide