Product Features

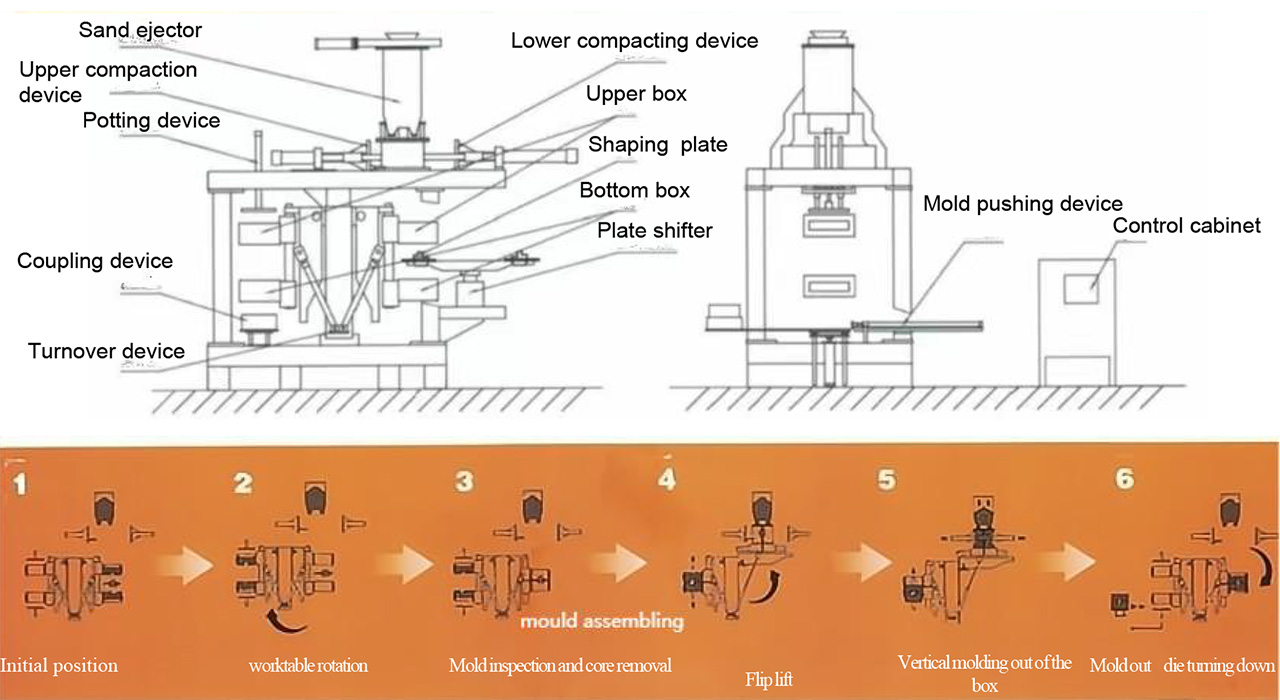

JN-FBO Vertical casting molding machine and Horizontal Parting

- Single station design, Compact size

The JN-FBO vertical casting molding machine is designed with a single station, making it compact and space-efficient. This design is ideal for foundries with limited floor space, allowing for optimal utilization of the available area.

- Horizontal Parting

The cast molding machine features horizontal parting, which is a common and efficient method in the foundry industry. This design facilitates easy mold separation and simplifies the casting process.

- Wide variety of mold dimensions

The JN-FBO offers a wide range of mold sizes to accommodate different molding and casting machine. This flexibility ensures that injection molding and casting machine can be used for various types of castings, making it a versatile addition to any foundry.

- Average max mold rate of 130 molds/hour

With an average maximum mold rate of 130 molds per hour, the JN-FBO sand casting production lines is designed for high productivity. This high output rate helps foundries increase their production capacity and meet higher demand.

- Virtually No Spill Sand or Strike-off Sand

The casting molding machine is designed to minimize spillage and strike-off sand, reducing waste and maintaining a cleaner working environment. This feature not only saves on material costs but also enhances overall operational efficiency.

- No Pits

The JN-FBO vertical casting molding machine operates without the need for pits, which simplifies the installation process and reduces the overall footprint of the sand casting equipments. This design also enhances safety by eliminating the risk associated with working in or around pits.

- No Bottom Boards required

The cast molding machine does not require bottom boards, which reduces the need for additional materials and maintenance. This feature contributes to lower operational costs and a more streamlined production process.

- Mold To Mold Consistency

The JN-FBO molding and casting machine ensures consistent mold quality from one mold to the next. This consistency is crucial for maintaining high-quality castings and reducing the likelihood of defects.

- Maintenance Friendly

The injection molding and casting machine is designed with maintenance in mind, making it easy to service and keep in optimal working condition. This feature helps reduce downtime and ensures that the machine remains reliable over its lifespan.

- Programmable Hydraulic Squeeze

The hydraulic squeeze system is programmable, allowing operators to adjust the pressure according to the specific requirements of each casting. This flexibility ensures high-quality molds and consistent results.

Vertical Casting molding machine (vertical casting molding machine) : A casting equipment that uses the vertical direction for mold (sand mold) production and parting. The opening and closing direction of its mold is perpendicular to the ground. It is usually suitable for the production of medium and small-sized castings and features a small floor space and convenient operation. It is commonly used in sand casting processes.

Horizontal Parting: The way in which the mold separates horizontally (parallel to the ground) during casting molding. That is, the parting surfaces of the upper mold (upper sand box) and the lower mold (lower sand box) are in a horizontal state. It is one of the most commonly used parting methods in casting production, suitable for various casting shapes, and facilitates core setting, mold closing and pouring operations.

Product Parameter

JN-FBO Vertical vertical casting molding machine and Horizontal Parting

| Model | Mold Size | Mold Height from (Cope) | Mold Height to (Drag) | Average Maximum Mold Rate (without Core setting) | Molding System |

|---|---|---|---|---|---|

JN-FBO3 | 20" x 24" | 5" - 8" | 5" - 8" | 130 molds/hour | Edge Blow + Squeeze |

| 500 mm x 600 mm | 130 mm - 200 mm | 130 mm - 200 mm | 130 molds/hour (27 seconds/mold) | Edge Blow + Squeeze | |

550 mm x 650 mm | 130 mm - 200 mm | 130 mm - 200 mm | 130 molds/hour (27 seconds/mold) | Edge Blow + Squeeze | |

JN-FBO4 | 24" X 28" (609.6 mm x 711.2 mm) | 7" - 10" | 7" - 10" | 100 molds/hour (36 seconds/mold) | Edge Blow + Squeeze |

| 600mm x 700mm) | 7" - 10" (180 mm - 254 mm) | 7" - 10" (180 mm - 254 mm) | 100 molds/hour | Edge Blow + Squeeze | |

| 650 mm x 750mm) | 7" - 10" (180 mm - 254 mm) | 7" - 10" (180 mm - 254 mm) | 100 molds/hour | Edge Blow + Squeeze | |

JN-FBO5 | 24" X 30" (609.6 mm x 762 mm) | 9" - 12" | 9" - 12" (230 mm- 300 mm) | 90 molds/hour | Edge Blow + Squeeze |

| 700 mm x 900 mm) | 9" - 12" (230 mm- 300 mm) | 9" - 12" (230 mm- 300 mm) | 90 molds/hour | Edge Blow + Squeeze | |

800 mm x 600 mm) | 9" - 12" (230 mm- 300 mm) | 9" - 12" (230 mm- 300 mm) | 90 molds/hour | Edge Blow + Squeeze |

Company Profile

JUNENG Machinery Co., Ltd., founded in 2011, is a prominent player in the global cast molding machine industry. As a subsidiary of Shengda Machinery Co., Ltd., JUNENG specializes in the development and production of cutting-edge molding and casting machine,vertical injection molding and casting machine, and complete casting assembly lines. With a strong focus on innovation, JUNENG integrates advanced technology, high efficiency, and reliability into every product.

Our Vision & Values

At JUNENG, our mission is clear: to lead the global cast molding machine market through a relentless focus on quality, innovation, and customer satisfaction. We adhere to the core principles of “Market-driven, Quality-focused” in everything we do. By leveraging the latest technology, we consistently push the boundaries of what is possible in injection molding and casting machine automation. We aim to provide our customers with not only cutting-edge molding and casting machine but also end-to-end solutions that enhance their production capabilities.

Pre-sale Service

1. Providing the most comfortable experience. Welcome clients to visit our head office and factory.

2. Saving money and time. Give clients most professional suggestions and help clients to choose the most suitable equipment type.

3. Providing the drawings. Help clients to establish the layout of the foundry and installation site.

4. Flexible payment terms.

Commitment to Innovation

As the casting industry evolves, so does JUNENG. We continuously monitor market trends and customer needs, adapting our solutions to meet the challenges of modern manufacturing. With strategic investments in research and development about sand cast molding machine, we are poised to remain at the forefront of industry advancements, providing customers with state-of-the-art molding and casting machine that improve performance, reliability, and cost-efficiency.

Conclusion

As a leading manufacturer of casting molding machine, JUNENG Machinery is dedicated to delivering world-class solutions that meet the evolving needs of the casting industry. With a commitment to quality, innovation, and customer satisfaction, we strive to remain the partner of choice for businesses looking to enhance their production capabilities and stay ahead in a competitive global market.

Our reputation for high-quality products and exceptional customer service has made us a preferred supplier for leading casting companies worldwide.