Product Features

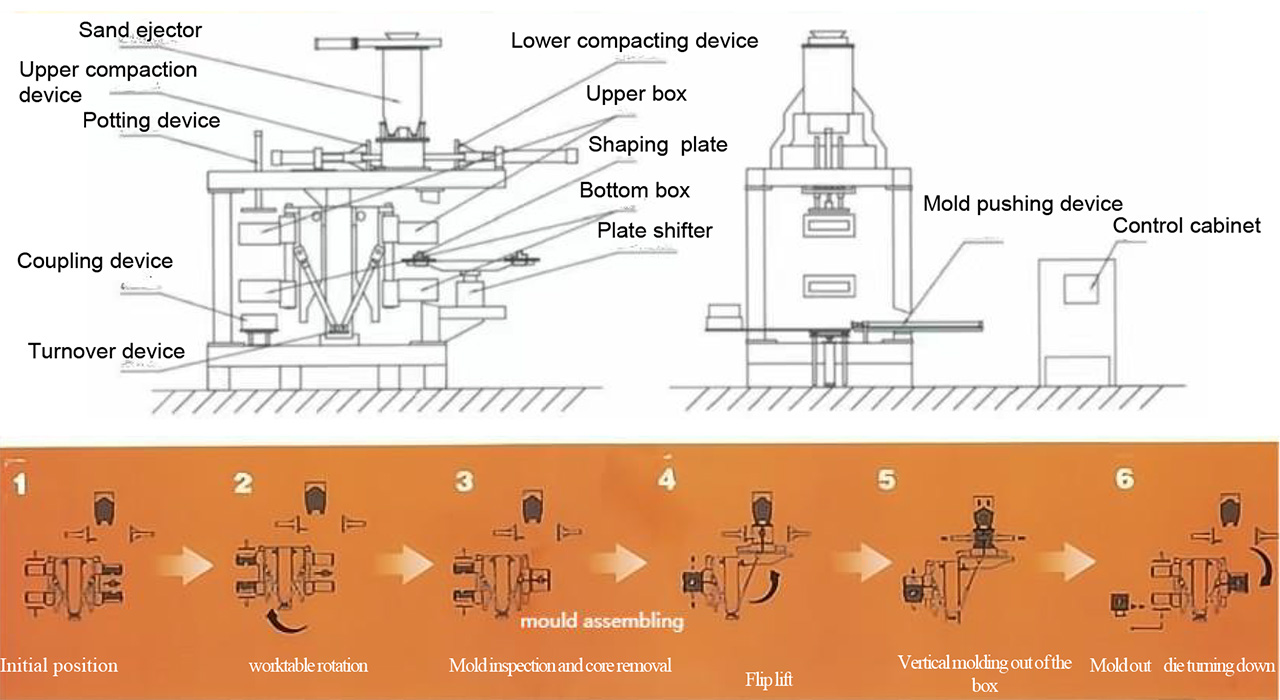

JN-FBO Vertical sand casting equipments and Horizontal Parting

Advanced Vertical Sand Casting with Precision Horizontal Parting Technology

Our Vertical Sand Casting Equipments and Horizontal Parting system combines two proven technologies for exceptional mold quality and operational efficiency. The vertical sand casting component ensures optimal sand density distribution by delivering sand perpendicular to the pattern plate, eliminating voids and ensuring perfect pattern replication. This green sand casting equipment is specifically designed for clay-bonded sand applications, maintaining consistent moisture levels throughout the mold cavity. The horizontal parting system provides clean, precise mold separation with minimal pattern drag, maintaining dimensional accuracy within ±0.15mm tolerance. This integrated approach makes it ideal for high-volume production of complex castings with reduced rejection rates.

**Single station design, Compact size**

The JN-FBO sand cast foundry equipment is designed with a single station, making it compact and space-efficient. This design is ideal for foundries with limited floor space, allowing for optimal utilization of the available area.

*The JN-FBO sand casting equipments offers a wide variety of mold size options to the foundry industry.

*The JN-FBO series of green sand casting equipment has been widely used in the foundry industry. Its robust design provides the reliability and longevity in a molding machine that foundries expect.

*The design of the JN-FBO industrial sand casting equipments has safeguards against the shifting of molds.

*Another key feature of the JN-FBO (sand casting safety equipment) is the ability to vary the molding height, which effectively adapts the mold size to various pattern profiles. The variable mold height also allows for the efficient use of sand.

*The various design features of the JN-FBO sand cast equipment can be an important tool for foundries to reduce scrap.

The JN-FBO sand cast equipment includes features that facilitate quick pattern changes. This capability is essential for foundries that need to switch between different casting designs frequently, reducing changeover time and increasing efficiency.

- **Left Hand or Right Hand models available**

The sand cast foundry equipment is available in both left-hand and right-hand configurations, providing options to suit the specific layout and workflow of different foundries.

- **Automatic drag shuttle mechanism for safe, comfortable, and easy core setting**

The automatic drag shuttle mechanism ensures that core setting is safe, comfortable, and easy. This feature enhances operator comfort and reduces the risk of injury, contributing to a safer work environment.

Product Parameter

JN-FBO Vertical sand casting equipments and Horizontal Parting

| Model | Mold Size | Mold Height from (Cope) | Mold Height to (Drag) | Average Maximum Mold Rate (without Core setting) | Molding System |

|---|---|---|---|---|---|

JN-FBO3 | 20" x 24" | 5" - 8" | 5" - 8" | 130 molds/hour | Edge Blow + Squeeze |

| 500 mm x 600 mm | 130 mm - 200 mm | 130 mm - 200 mm | 130 molds/hour (27 seconds/mold) | Edge Blow + Squeeze | |

550 mm x 650 mm | 130 mm - 200 mm | 130 mm - 200 mm | 130 molds/hour (27 seconds/mold) | Edge Blow + Squeeze | |

JN-FBO4 | 24" X 28" (609.6 mm x 711.2 mm) | 7" - 10" | 7" - 10" | 100 molds/hour (36 seconds/mold) | Edge Blow + Squeeze |

| 600mm x 700mm) | 7" - 10" (180 mm - 254 mm) | 7" - 10" (180 mm - 254 mm) | 100 molds/hour | Edge Blow + Squeeze | |

| 650 mm x 750mm) | 7" - 10" (180 mm - 254 mm) | 7" - 10" (180 mm - 254 mm) | 100 molds/hour | Edge Blow + Squeeze | |

JN-FBO5 | 24" X 30" (609.6 mm x 762 mm) | 9" - 12" | 9" - 12" (230 mm- 300 mm) | 90 molds/hour | Edge Blow + Squeeze |

| 700 mm x 900 mm) | 9" - 12" (230 mm- 300 mm) | 9" - 12" (230 mm- 300 mm) | 90 molds/hour | Edge Blow + Squeeze | |

800 mm x 600 mm) | 9" - 12" (230 mm- 300 mm) | 9" - 12" (230 mm- 300 mm) | 90 molds/hour | Edge Blow + Squeeze |

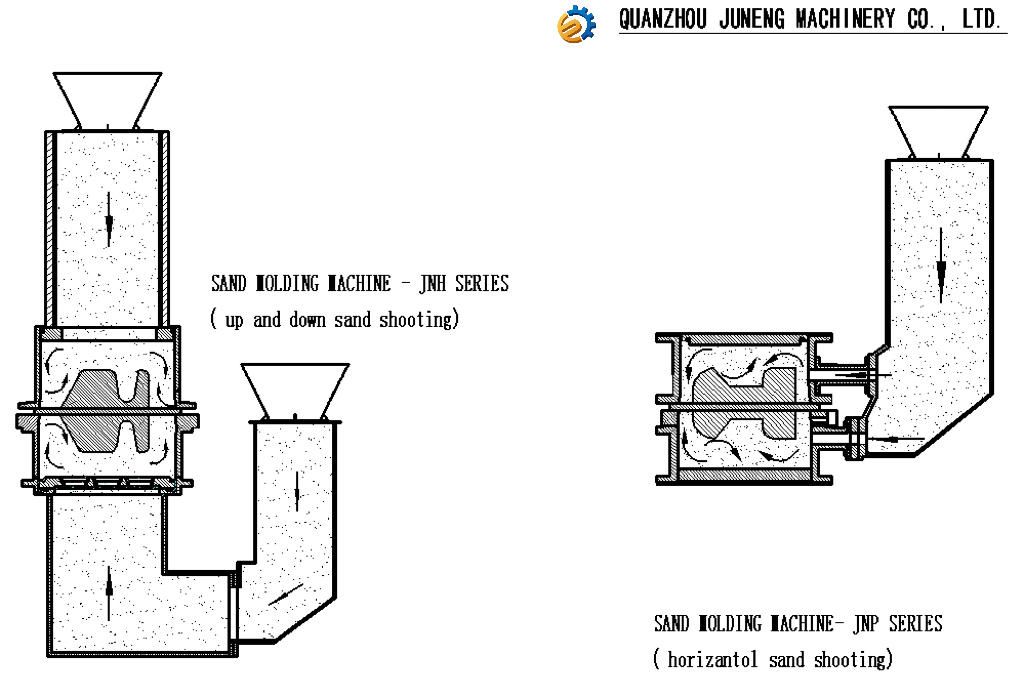

Vertical Sand Casting Equipments

It refers to the specialized equipment used in the vertical sand casting process, mainly including sand treatment systems (such as sand mixers, sand regeneration equipment), molding machines (vertical parting molding machines), pouring equipment, and shakeout cleaning equipment, etc. Its characteristic is that the parting surface of the sand mold is in a vertical state, which is suitable for the mass production of medium and small-sized castings. It has the advantages of high production efficiency, high degree of automation, and good dimensional accuracy of castings. It is commonly seen in the casting production of automotive parts, construction machinery accessories and other fields.

Horizontal Parting

A parting method in casting technology refers to the fact that the parting surface of the sand mold (the junction surface of the upper and lower sand molds) is in a horizontal direction. Horizontal parting facilitates core setting and closing operations, and is suitable for the production of complex-shaped or large castings, especially for manual molding or semi-automatic molding. Compared with vertical parting, horizontal parting is more flexible in aspects such as demolding of castings and placement of sand cores, but its production efficiency is usually slightly lower. It is widely applied in the casting process of machine tool beds, large box-type castings, etc.

Global Reach & Industry Leadership

With a state-of-the-art manufacturing facility spanning over 10,000 square meters, JUNENG has firmly established itself as an industry leader. Our sand cast equipment are trusted by customers in over 20 countries, including the United States, Brazil, India, Russia, and Vietnam. Our global reach is further supported by a network of authorized agents and sales offices, ensuring that we can deliver localized service and technical support to all our international clients.

In addition to providing high-quality sand cast foundry equipment, JUNENG maintains a dedicated after-sales service system designed to offer timely technical support and assistance. Whether through direct service centers or our authorized partners, we are committed to creating lasting value for our customers and ensuring the seamless operation of their sand casting equipments.

Key Advantages

1、Vertical sand casting with horizontal parting for optimal mold quality

2、Comprehensive safety features and robust industrial design

3、Energy-efficient operation with smart control systems

4、Suitable for green sand and various casting applications

5、Low maintenance design with IoT connectivity

Conclusion

As a leading manufacturer of sand cast foundry equipment , JUNENG Machinery is dedicated to delivering world-class solutions that meet the evolving needs of the casting industry. With a commitment to quality, innovation, and customer satisfaction, we strive to remain the partner of choice for businesses looking to enhance their production capabilities and stay ahead in a competitive global market.

Our reputation for high-quality products and exceptional customer service has made us a preferred supplier for leading casting companies worldwide.