Product Features

JN-FBO Vertical Sand casting molding machine and Horizontal Parting

Vertical Sand casting molding machine and Horizontal Parting,stable and reliable, can realize automatic operation, simple and convenient operation, smallarea, highproductivity, suitable for the production of automotive parts,such as cylinder head, flywheel she, brake pliers, etc. Also suitable forthe production of pipe,valve. shaft, cover plate parts, such as through, three links, bends, pipe clamps and so on. ls the most popular molding egquipment in the foundry.

1. Precision Vertical Sand Casting with Efficient Horizontal Parting Technology

As leading sand casting molding machine manufacturers, we present our advanced Vertical Sand Casting Molding Machine and Horizontal Parting system, engineered for exceptional performance in modern foundries. This innovative equipment combines vertical sand shooting technology with precision horizontal parting mechanisms to deliver superior mold quality and production efficiency. The vertical shooting system ensures optimal sand density distribution by delivering sand perpendicular to the pattern plate, eliminating voids and ensuring perfect pattern replication. This technology is complemented by a robust horizontal parting system that provides clean, precise mold separation with minimal pattern drag, maintaining dimensional accuracy within ±0.1mm tolerance. This integrated approach makes our machines ideal for high-volume production of complex castings with reduced rejection rates.

2. Manufacturing Excellence from Trusted Industry Leaders

Our sand casting molding machine factories employ state-of-the-art manufacturing processes to produce equipment that meets the highest international standards. As experienced sand casting molding machine manufacturers, we incorporate premium materials and precision engineering in every machine. The robust construction features reinforced steel frames, hardened guide mechanisms, and wear-resistant components designed for continuous operation in demanding foundry environments. Our manufacturing facilities utilize advanced CNC machinery and rigorous quality control processes to ensure every machine delivers reliable performance and long-term durability. This commitment to excellence has established us as preferred sand casting molding machine exporters to foundries worldwide.

3. Automated Production with Intelligent Control Systems

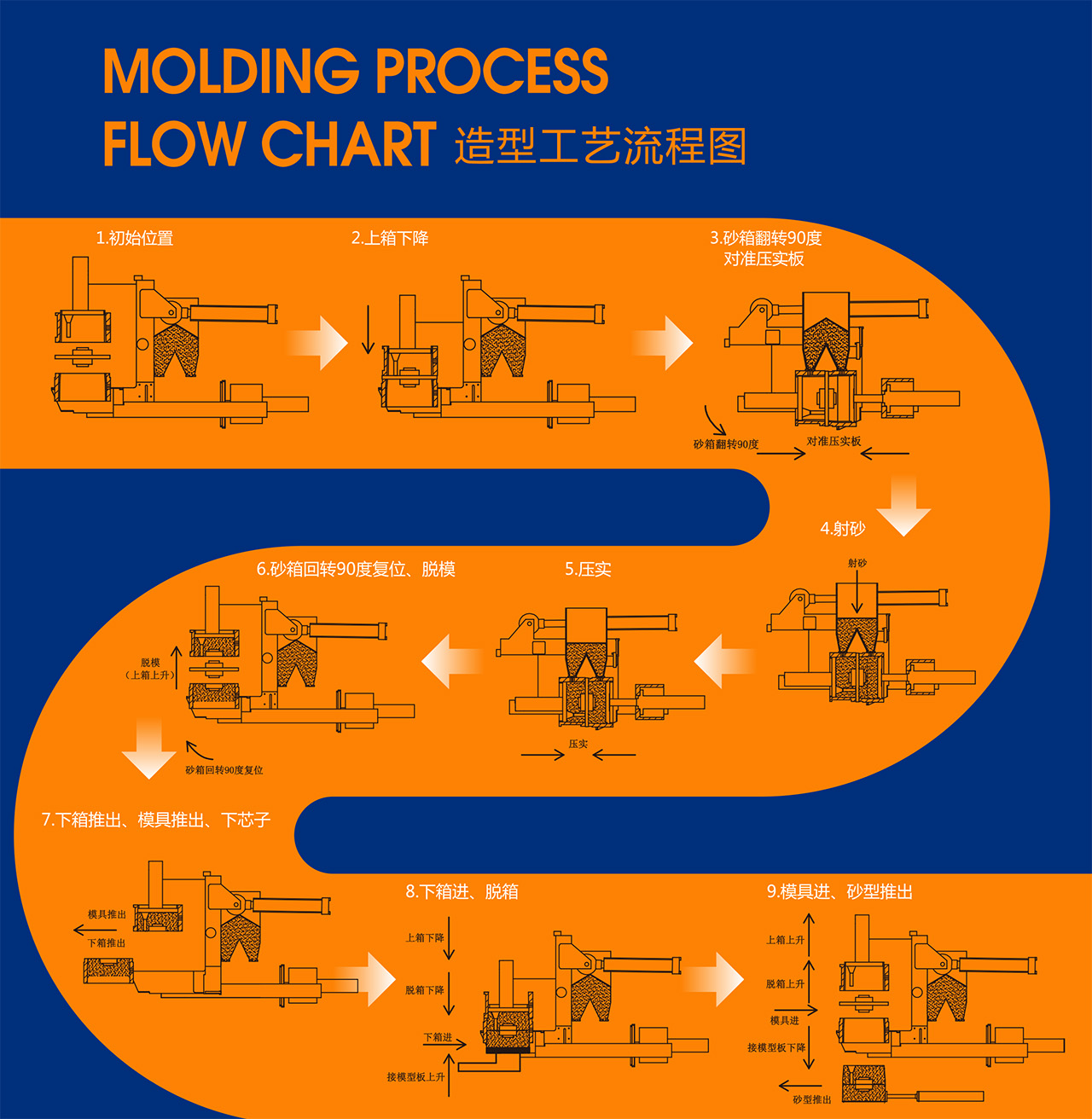

This advanced equipment represents the pinnacle of automation in foundry technology. The PLC-controlled system manages the entire molding process from sand feeding to mold ejection with precision accuracy. As innovative sand casting molding machine manufacturers, we integrate intelligent features including automatic pattern changing systems, real-time sand moisture monitoring, and self-diagnostic capabilities. The machine offers production rates of 200-450 molds per hour with consistent mold hardness of 90-95 HB. The automated lubrication system and maintenance alerts ensure optimal performance while reducing operational costs. Our sand casting molding machine factory incorporates the latest IoT technology for remote monitoring and predictive maintenance capabilities.

4. Global Export Quality and Reliability

As renowned sand casting molding machine exporters, we ensure every machine meets international quality and safety standards. Our equipment features comprehensive safety systems including emergency stop circuits, mechanical interlocks, and guarded moving parts. The vertical shooting system is enclosed within protective housing that contains sand and dust, while the horizontal parting mechanism features safety sensors that prevent operation during maintenance. This robust design ensures reliable 24/7 operation with minimal downtime. Our global network of service technicians and spare parts availability ensures prompt support for clients worldwide, making us trusted partners for foundries seeking reliable sand casting molding machine manufacturers.

Product Parameter

JN-FBO Vertical Sand casting molding machine and Horizontal Parting

| Model | Mold Size | Mold Height from (Cope) | Mold Height to (Drag) | Average Maximum Mold Rate (without Core setting) | Molding System |

|---|---|---|---|---|---|

JN-FBO3 | 20" x 24" | 5" - 8" | 5" - 8" | 130 molds/hour | Edge Blow + Squeeze |

| 500 mm x 600 mm | 130 mm - 200 mm | 130 mm - 200 mm | 130 molds/hour (27 seconds/mold) | Edge Blow + Squeeze | |

550 mm x 650 mm | 130 mm - 200 mm | 130 mm - 200 mm | 130 molds/hour (27 seconds/mold) | Edge Blow + Squeeze | |

JN-FBO4 | 24" X 28" (609.6 mm x 711.2 mm) | 7" - 10" | 7" - 10" | 100 molds/hour (36 seconds/mold) | Edge Blow + Squeeze |

| 600mm x 700mm) | 7" - 10" (180 mm - 254 mm) | 7" - 10" (180 mm - 254 mm) | 100 molds/hour | Edge Blow + Squeeze | |

| 650 mm x 750mm) | 7" - 10" (180 mm - 254 mm) | 7" - 10" (180 mm - 254 mm) | 100 molds/hour | Edge Blow + Squeeze | |

JN-FBO5 | 24" X 30" (609.6 mm x 762 mm) | 9" - 12" | 9" - 12" (230 mm- 300 mm) | 90 molds/hour | Edge Blow + Squeeze |

| 700 mm x 900 mm) | 9" - 12" (230 mm- 300 mm) | 9" - 12" (230 mm- 300 mm) | 90 molds/hour | Edge Blow + Squeeze | |

800 mm x 600 mm) | 9" - 12" (230 mm- 300 mm) | 9" - 12" (230 mm- 300 mm) | 90 molds/hour | Edge Blow + Squeeze |

About Us

Founded on a foundation of excellence, JUNENG is dedicated to providing intelligent and cost-effective solutions to the casting industry. We are a high-tech research and development enterprise committed to advancing the field of Sand casting molding machine. Our comprehensive range of products includes automated sand cast foundry equipment and fully integrated casting lines designed to meet the needs of small to medium-sized casting operations.

Among our flagship products, Our JN-FBO Vertical sand casting equipment and Horizontal Parting delivers high precision and efficiency for advanced casting applications. The JN-AMF Double Station Vertical casting sand equipment and Horizontal Parting enhances productivity with its dual-station design, delivering high-precision results. The JNH Top and Bottom Sand Shooting equipment used in sand casting offers a versatile and cost-effective solution for various molding applications. And the JNP Horizontal Sand Shooting equipment needed for sand casting provides an economical option for simpler casting needs.

Through continuous technological advancements and a deep commitment to quality, we ensure that our sand casting equipments are among the most reliable and efficient on the market. Our systems help businesses reduce labor costs, increase operational efficiency, and improve overall casting quality, making us a trusted partner for companies worldwide.

Our Vision & Values

At JUNENG, our mission is clear: to lead the global green sand casting equipment market through a relentless focus on quality, innovation, and customer satisfaction. We adhere to the core principles of “Market-driven, Quality-focused” in everything we do. By leveraging the latest technology, we consistently push the boundaries of what is possible in industrial sand casting equipments automation. We aim to provide our customers with not only cutting-edge sand casting safety equipment but also end-to-end solutions that enhance their production capabilities.

Commitment to Innovation

As the casting industry evolves, so does JUNENG. We continuously monitor market trends and customer needs, adapting our solutions to meet the challenges of modern manufacturing. With strategic investments in research and development about sand green sand casting equipment, we are poised to remain at the forefront of industry advancements, providing customers with state-of-the-art industrial sand casting equipments that improve performance, reliability, and cost-efficiency.

Technical Characteristics

1、The machine is stable,low power consumption,and long lifetime

2、High level of automation,easy control,and low labor cost.

3、Highly standardized,good parts interchangeable,fast and low-cost maintenance.

4、The sand could be compacted both inside and outside according to technical requirements. which make the sand mold better

5、Mold release agent is sprayed automatically,which makes the demolding smoothly,casting surface glossily,and no defect in the sand mold

6、Electric cabinet and hydraulic station are all installed in the machine,which makes them compact and easy maintenance.

7、Low failure rate,and the machine can diagnose the failure by its own.

Conclusion

As a leading manufacturer of sand cast foundry equipment , JUNENG Machinery is dedicated to delivering world-class solutions that meet the evolving needs of the casting industry. With a commitment to quality, innovation, and customer satisfaction, we strive to remain the partner of choice for businesses looking to enhance their production capabilities and stay ahead in a competitive global market.

Our reputation for high-quality products and exceptional customer service has made us a preferred supplier for leading casting companies worldwide.