Product Features

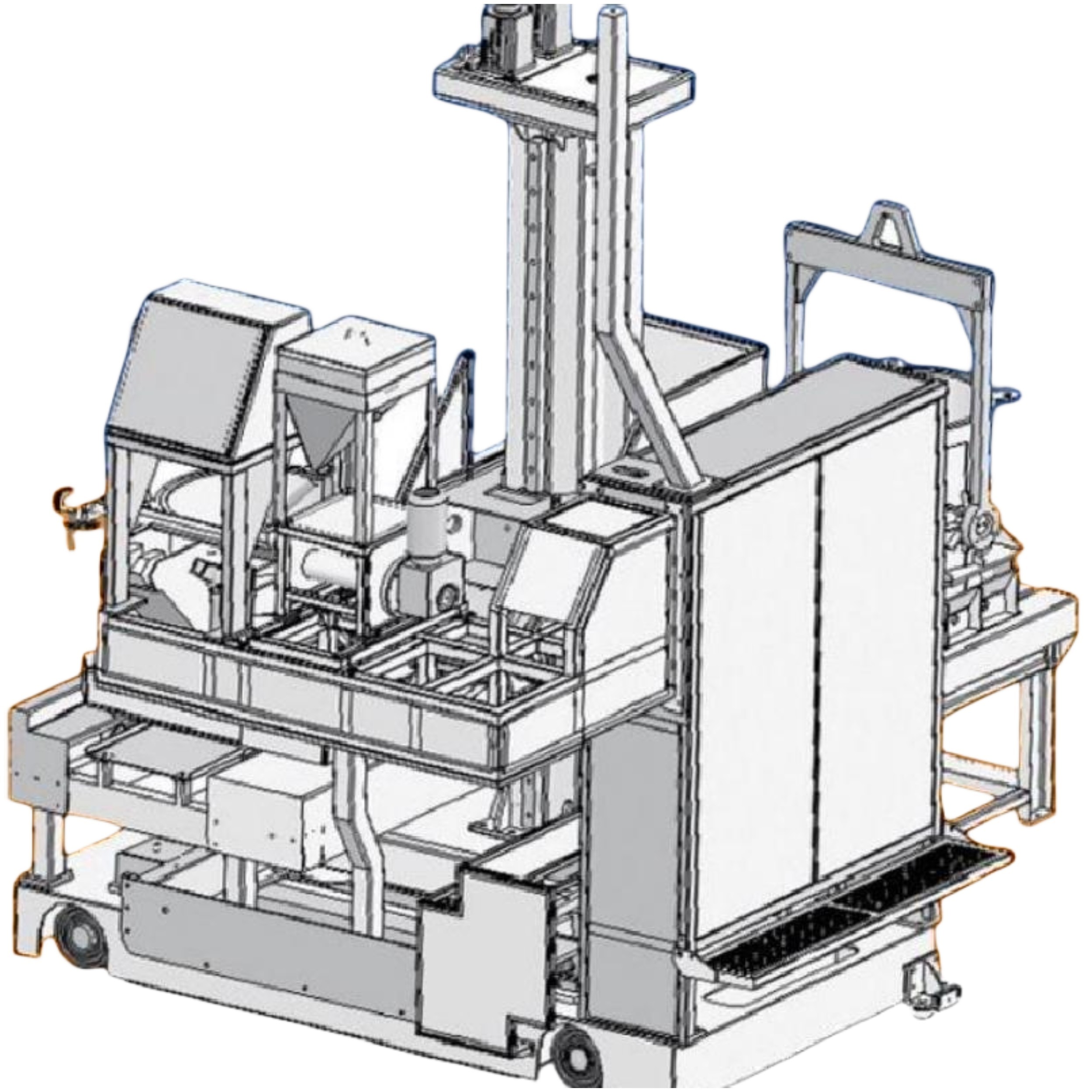

The JNP Horizontal green sand moulding machines is a high-performance, servo-driven molding system designed for stable operation, minimal energy consumption, and consistent casting quality. Featuring a horizontal sand shooting mechanism and a servo-controlled hydraulic system, the JNP series offers a reliable solution for foundries seeking high automation, low labor requirements, and efficient production.

1.Energy-Efficient and Environmentally Conscious Design

Our green sand mould machine incorporates advanced energy-saving technologies that reduce operating costs while maintaining high productivity. The horizontal shooting system optimizes sand usage, reducing waste by 30% through precise shot control and efficient recycling. The machine features enclosed dust collection systems and noise reduction technologies, creating a cleaner and safer working environment. As a modern sand mold machine, it offers IoT connectivity for real-time monitoring of production data, energy consumption, and maintenance needs, enabling predictive maintenance and continuous process optimization for sustainable foundry operations.

2.Superior Mold Quality with Precision Engineering

Engineered as a specialized green sand mould machine, this equipment excels in producing high-density molds for complex castings. The horizontal sand shooting system delivers consistent mold hardness of 90-95 HB throughout the cavity, ensuring structural integrity during pouring operations. The machine's technology shares principles with sand injection blow molding machine in its precision delivery system, providing complete pattern filling without density variations. This results in significant reduction of casting defects such as sand inclusion and veining, achieving rejection rates below 0.4% while maintaining optimal green sand properties throughout the production process.

3.Comprehensive Production Line Integration

This machine serves as the core component of a complete green sand moulding machine line, seamlessly integrating with automatic sand preparation systems, mold handling equipment, and pouring lines. The green sand automatic moulding machine features standardized interfaces for easy connection to auxiliary equipment, including automatic pattern changers and sand recycling systems. The horizontal shooting technology ensures compatibility with various flask sizes and pattern configurations, while the robust construction handles continuous operation with minimal maintenance requirements. This integrated approach optimizes floor space utilization and creates a efficient, continuous production flow.

4.Advanced Horizontal Sand Shooting Technology for Green Sand Applications

Our green sand moulding machines with horizontal sand shooting represent a breakthrough in foundry technology, specifically engineered for optimal clay-bonded sand performance. The horizontal shooting system delivers sand parallel to the parting line, ensuring uniform density distribution and perfect pattern replication. This technology maintains consistent moisture levels throughout the mold cavity, preventing dry spots and ensuring optimal binder activation. As part of a complete green sand moulding machine line, this system achieves 92-96% compaction efficiency, producing molds with exceptional dimensional accuracy and surface finish while reducing casting defects by up to 50% compared to conventional methods.

5. Fully Automated High-Speed Production System

This green sand automatic moulding machine delivers complete automation from sand feeding to mold ejection. The integrated PLC system controls the horizontal shooting process, compaction force, and pattern stripping with precision accuracy. The automated sand mold machine features intelligent moisture control systems that continuously monitor and adjust sand conditions, ensuring consistent mold quality. With production rates of 200-450 molds per hour and dimensional accuracy within ±0.2mm, this system reduces labor requirements by 65% while improving overall productivity by 55% compared to manual operations, making it ideal for high-volume foundry production.

Product Parameter

JNP Horizontal green sand moulding machine line

| Model | Mold Size | Mold Height from (Cope) | Mold Height to (Drag) | Average Maximum Mold Rate (without Core setting) | Molding System |

|---|---|---|---|---|---|

| JNP3545 | (300~380)*(400~480)mm | 130~250mm | 130~250mm | 26 seconds/mold (without core-setting time) | Edge Blow + Squeeze |

| JNP4555 | (400~480)*(500~580)mm | 130~250mm | 130~250mm | 26 seconds/mold (without core-setting time) | Edge Blow + Squeeze |

JNP5565 | (500~580)*(600~680)mm | 130~250mm | 130~250mm | 26 seconds/mold (without core-setting time) | Edge Blow + Squeeze |

JNP6575 | (600~680)*(700~780)m | 130~250mm | 130~250mm | 26 seconds/mold (without core-setting time) | Edge Blow + Squeeze |

JNP7585 | (700~780)*(800~880)mm | 130~250mm | 130~250mm | 26 seconds/mold (without core-setting time) | Edge Blow + Squeeze |

Company Profile

JUNENG Machinery Co., Ltd., founded in 2011, is a prominent player in the global sand mold machine industry. As a subsidiary of Shengda Machinery Co., Ltd., JUNENG specializes in the development and production of cutting-edge sand injection blow molding machine,vertical green sand automatic moulding machine, and complete casting assembly lines. With a strong focus on innovation, JUNENG integrates advanced technology, high efficiency, and reliability into every product.

About Us

Founded on a foundation of excellence, JUNENG is dedicated to providing intelligent and cost-effective solutions to the casting industry. We are a high-tech research and development enterprise committed to advancing the field of green sand mould machine . Our comprehensive range of products includes automated green sand moulding machines and fully integrated casting lines designed to meet the needs of small to medium-sized casting operations.

Among our flagship products, Our JN-FBO Vertical sand casting molding machines and Horizontal Parting delivers high precision and efficiency for advanced casting applications. The JN-AMF Double Station Vertical sand casting molding machinery and Horizontal Parting enhances productivity with its dual-station design, delivering high-precision results. The JNH Top and Bottom sand moulding machinery used in sand casting offers a versatile and cost-effective solution for various molding applications. And the JNP green sand moulding machine line provides an economical option for simpler casting needs.

Through continuous technological advancements and a deep commitment to quality, we ensure that our sand mold machine are among the most reliable and efficient on the market. Our systems help businesses reduce labor costs, increase operational efficiency, and improve overall casting quality, making us a trusted partner for companies worldwide.

Global Reach & Industry Leadership

With a state-of-the-art manufacturing facility spanning over 10,000 square meters, JUNENG has firmly established itself as an industry leader. Our green sand moulding machine line are trusted by customers in over 20 countries, including the United States, Brazil, India, Russia, and Vietnam. Our global reach is further supported by a network of authorized agents and sales offices, ensuring that we can deliver localized service and technical support to all our international clients.

In addition to providing high-quality sand mold machine , JUNENG maintains a dedicated after-sales service system designed to offer timely technical support and assistance. Whether through direct service centers or our authorized partners, we are committed to creating lasting value for our customers and ensuring the seamless operation of their sand injection blow molding machine.

Commitment to Innovation

As the casting industry evolves, so does JUNENG. We continuously monitor market trends and customer needs, adapting our solutions to meet the challenges of modern manufacturing. With strategic investments in research and development about sand green sand automatic moulding machine, we are poised to remain at the forefront of industry advancements, providing customers with state-of-the-art green sand mould machine that improve performance, reliability, and cost-efficiency.

OUR SERVICE

We have strict reguirements on management system and product quality, and perfect pre-sale and after-sales service.

Pre-sale service

About our machinery, if you are interested in contact us, can be customized according toyour requirements for you.

After-sales service

Whole day online for you to answer through mobile phone, WhatsApp, wechat. Afterpurchasing our products, our technicians can help you install and maintain the machineryaccording to your location.

Payment

Telegraphic transfer,30% deposit,70% before friendly goods.