Product Features

The JNP Horizontal green sand moulding machine is a high-performance, servo-driven molding system designed for stable operation, minimal energy consumption, and consistent casting quality. Featuring a horizontal sand shooting mechanism and a servo-controlled hydraulic system, the JNP series offers a reliable solution for foundries seeking high automation, low labor requirements, and efficient production.

Fully Automated Operation for Maximum Production Efficiency

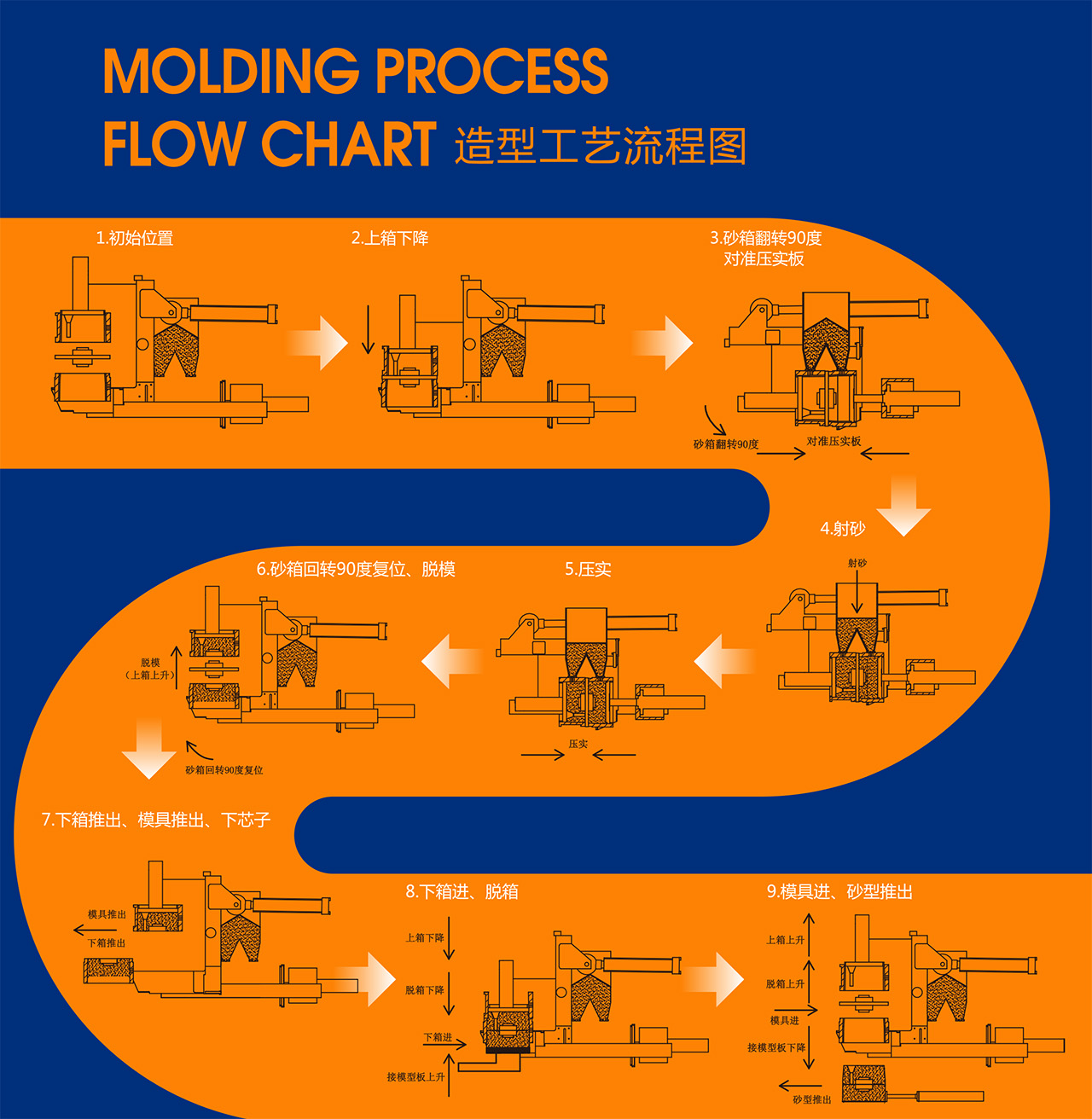

This automatic green sand moulding machine delivers complete, hands-free operation from sand feeding to mold ejection. The integrated PLC system precisely controls the horizontal shooting process, compaction force, and pattern stripping with cycle times optimized for 200-450 molds per hour. As a sophisticated green sand automatic moulding machine, it features intelligent moisture control systems that continuously monitor and adjust sand conditions, ensuring consistent mold quality shot after shot. The automation package includes self-diagnostic capabilities, real-time monitoring sensors, and IoT connectivity for seamless integration into smart foundry environments, ensuring uninterrupted production with minimal operator intervention.

1.Accept customized equipment based on customers' exact requirements

2. Greatly improve production efficiency and save labor costs.

3.Small occupied areas and save land

4. lmprove casting quality and stability, high sand molding compactness.

5. The height of the sand box can be adjusted and set according to the thickness of the molding box.

6. Can be equipped with conveyor lines, can also be produced in a single machine.

7The hvdrauic and electronic control parts ofthe machine are alimported components, which are stable. reliable, hioh precision.

Product Parameter

JNP Horizontal foundry green sand moulding machine

| Model | Mold Size | Mold Height from (Cope) | Mold Height to (Drag) | Average Maximum Mold Rate (without Core setting) | Molding System |

|---|---|---|---|---|---|

| JNP3545 | (300~380)*(400~480)mm | 130~250mm | 130~250mm | 26 seconds/mold (without core-setting time) | Edge Blow + Squeeze |

| JNP4555 | (400~480)*(500~580)mm | 130~250mm | 130~250mm | 26 seconds/mold (without core-setting time) | Edge Blow + Squeeze |

JNP5565 | (500~580)*(600~680)mm | 130~250mm | 130~250mm | 26 seconds/mold (without core-setting time) | Edge Blow + Squeeze |

JNP6575 | (600~680)*(700~780)m | 130~250mm | 130~250mm | 26 seconds/mold (without core-setting time) | Edge Blow + Squeeze |

JNP7585 | (700~780)*(800~880)mm | 130~250mm | 130~250mm | 26 seconds/mold (without core-setting time) | Edge Blow + Squeeze |

Company Profile

JUNENG Machinery Co., Ltd., founded in 2011, is a prominent player in the global foundry sand moulding machine industry. As a subsidiary of Shengda Machinery Co., Ltd., JUNENG specializes in the development and production of cutting-edge green sand automatic moulding machine,vertical green sand mould machine, and complete casting assembly lines. With a strong focus on innovation, JUNENG integrates advanced technology, high efficiency, and reliability into every product.

Our Vision & Values

At JUNENG, our mission is clear: to lead the global green sand moulding machinemarket through a relentless focus on quality, innovation, and customer satisfaction. We adhere to the core principles of “Market-driven, Quality-focused” in everything we do. By leveraging the latest technology, we consistently push the boundaries of what is possible in foundry green sand moulding machine sand automation. We aim to provide our customers with not only cutting-edge foundry sand moulding machine but also end-to-end solutions that enhance their production capabilities.

Global Reach & Industry Leadership

With a state-of-the-art manufacturing facility spanning over 10,000 square meters, JUNENG has firmly established itself as an industry leader. Our green sand moulding machine are trusted by customers in over 20 countries, including the United States, Brazil, India, Russia, and Vietnam. Our global reach is further supported by a network of authorized agents and sales offices, ensuring that we can deliver localized service and technical support to all our international clients.

In addition to providing high-quality automatic green sand moulding machine , JUNENG maintains a dedicated after-sales service system designed to offer timely technical support and assistance. Whether through direct service centers or our authorized partners, we are committed to creating lasting value for our customers and ensuring the seamless operation of their green sand moulding machine .

Advantages

1.Over 14 years of experience in casting equipment.

2.Most competitive price and quality.

3.Short delivery time.

4.Instant aftersale service online.

5.Import and Export License.

Pre-sale Service

1. Providing the most comfortable experience. Welcome clients to visit our head office and factory.

2. Saving money and time. Give clients most professional suggestions and help clients to choose the most suitable equipment type.

3. Providing the drawings. Help clients to establish the layout of the foundry and installation site.

4. Flexible payment terms.

Conclusion

As a leading manufacturer of foundry sand moulding machine, JUNENG Machinery is dedicated to delivering world-class solutions that meet the evolving needs of the casting industry. With a commitment to quality, innovation, and customer satisfaction, we strive to remain the partner of choice for businesses looking to enhance their production capabilities and stay ahead in a competitive global market.

Our reputation for high-quality products and exceptional customer service has made us a preferred supplier for leading casting companies worldwide.