Product Features

JNH series -- green sand molding machines with up and down sand shooting

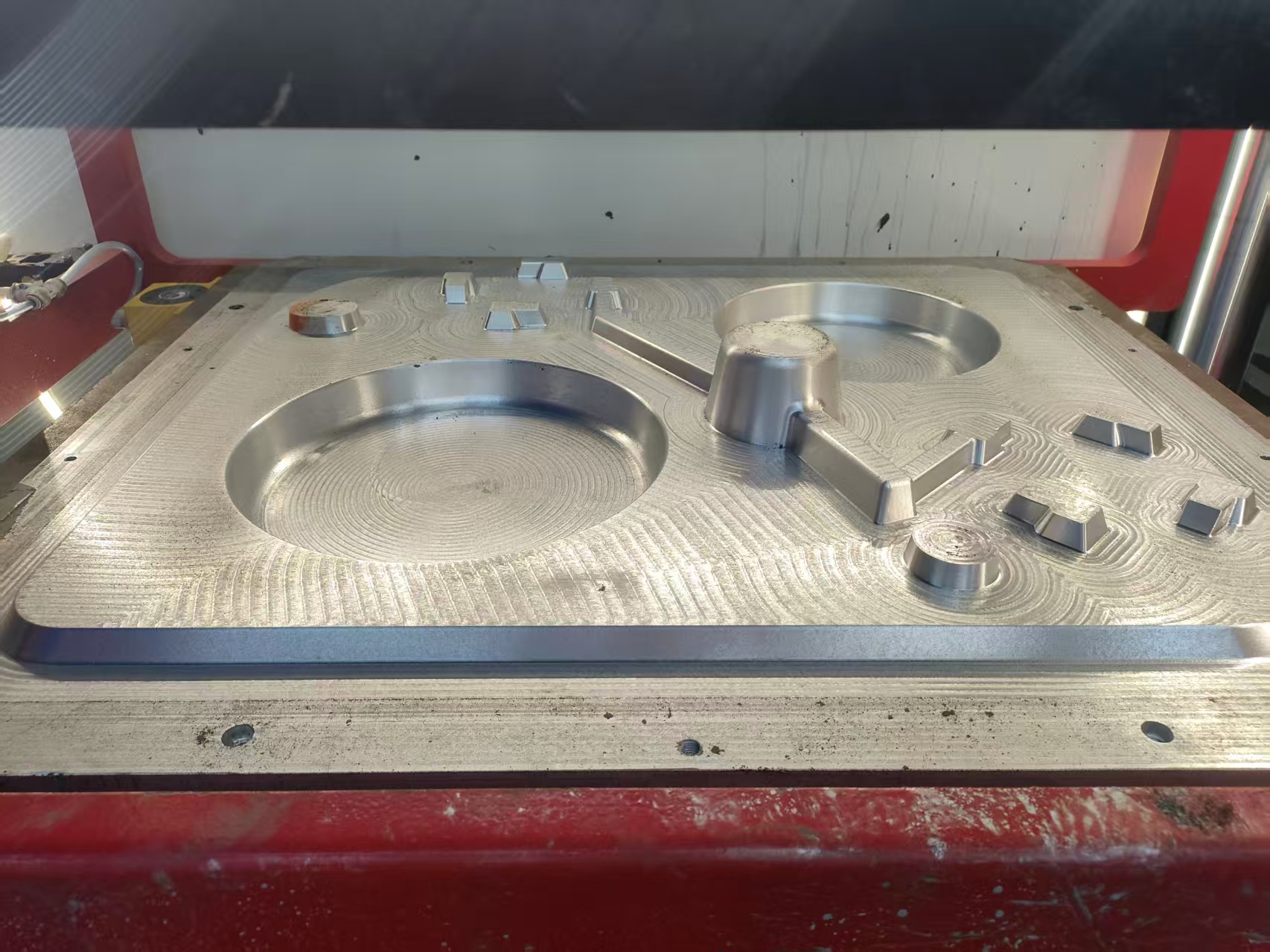

1. Revolutionary Bidirectional Green Sand Compaction Technology

Our green sand molding machines with up and down sand shooting way represent a breakthrough in foundry technology. This system utilizes bidirectional high-pressure sand injection to achieve unparalleled mold density and uniformity. As a high pressure sand injection molding machine, it operates at 0.5-0.8 MPa to ensure complete pattern replication without voids or weak spots. The simultaneous top and bottom sand delivery creates perfect compaction throughout the mold cavity, making it ideal for producing complex castings with intricate details and thin walls. This advanced approach eliminates traditional limitations of conventional green sand processes, delivering 30% higher mold hardness and 40% fewer casting defects.

2. Fully Automated Precision Molding System

This auto sand injection molding machine delivers complete automation for modern foundries. The integrated PLC system controls every aspect of the molding process: automatic sand feeding, precision bidirectional shooting, high-pressure compaction, and mold ejection. The auto jector sand injection molding machine capability ensures consistent shot-after-shot performance with minimal human intervention. With a production capacity of 180-400 molds per hour and dimensional accuracy within ±0.25mm, this system significantly reduces labor costs while improving overall productivity by 50% compared to conventional molding methods.

3. High-Pressure Performance for Superior Mold Quality

Engineered as a high pressure sand injection molding machine, this equipment delivers exceptional mold quality for demanding applications. The combination of bidirectional sand shooting and high-pressure compaction (1,500-2,200 kN) achieves mold hardness of 90-95 HB, ensuring rigid molds that withstand handling and pouring operations. This sand injection blow molding machine technology provides perfect pattern reproduction with excellent surface finish, reducing cleaning and machining time by 35%. The system maintains consistent quality even with varying sand conditions, making it exceptionally reliable for high-volume production environments.

4. Industrial-Grade Durability and Efficiency

Built for 24/7 operation, this auto jector sand injection molding machine features heavy-duty construction with reinforced steel frame, tungsten-carbide shooting nozzles, and industrial-grade hydraulics. The machine's robust design ensures reliable performance in the most demanding foundry conditions with minimal maintenance requirements. Energy-efficient servo motors reduce power consumption by 25%, while the optimized sand delivery system minimizes waste by ensuring 98% utilization of molding sand. The enclosed design contains dust and noise, creating a cleaner and safer working environment.

5. Versatile Application Capability and Smart Integration

This advanced green sand molding machine accommodates a wide range of foundry applications, from small precision components to large industrial castings. The bidirectional shooting technology handles complex geometries with deep pockets and undercuts that challenge conventional machines. As a sand injection blow molding machine, it offers exceptional flexibility for various pattern sizes and configurations. Smart factory compatible with IoT connectivity, the machine provides real-time monitoring of production data, maintenance alerts, and performance analytics. This enables predictive maintenance and continuous process optimization for maximum efficiency and uptime.

Product Parameter

JNH series -- sand injection blow molding machine with up and down sand shooting

| Model | Mold Size | Mold Height from (Cope) | Mold Height to (Drag) | Average Maximum Mold Rate (without Core setting) | Molding System |

|---|---|---|---|---|---|

| JNH3545 | (300~380)*(400~480)mm | 130~250mm | 130~250mm | 26 seconds/mold (without core-setting time) | Edge Blow + Squeeze |

| JNH4555 | (400~480)*(500~580)mm | 130~250mm | 130~250mm | 26 seconds/mold (without core-setting time) | Edge Blow + Squeeze |

JNH5565 | (500~580)*(600~680)mm | 130~250mm | 130~250mm | 26 seconds/mold (without core-setting time) | Edge Blow + Squeeze |

JNH6575 | (600~680)*(700~780)m | 130~250mm | 130~250mm | 26 seconds/mold (without core-setting time) | Edge Blow + Squeeze |

JNH7585 | (700~780)*(800~880)mm | 130~250mm | 130~250mm | 26 seconds/mold (without core-setting time) | Edge Blow + Squeeze |

Company Profile

JUNENG Machinery Co., Ltd., founded in 2011, is a prominent player in the global green sand molding machines industry. As a subsidiary of Shengda Machinery Co., Ltd., JUNENG specializes in the development and production of cutting-edge high pressure sand injection molding machine,vertical high pressure sand injection molding machine, and complete casting assembly lines. With a strong focus on innovation, JUNENG integrates advanced technology, high efficiency, and reliability into every product.

About Us

Founded on a foundation of excellence, JUNENG is dedicated to providing intelligent and cost-effective solutions to the casting industry. We are a high-tech research and development enterprise committed to advancing the field of auto sand injection molding machine. Our comprehensive range of products includes automated auto jector sand injection molding machine and fully integrated casting lines designed to meet the needs of small to medium-sized casting operations.

Among our flagship products, Our JN-FBO Vertical green sand molding machine and Horizontal Parting delivers high precision and efficiency for advanced casting applications. The JN-AMF Double Station Vertical automatic green sand molding machine and Horizontal Parting enhances productivity with its dual-station design, delivering high-precision results. The JNH Top and Bottom Sand Shooting equipment used in sand casting offers a versatile and cost-effective solution for various molding applications. And the JNP sand injection blow molding machine provides an economical option for simpler casting needs.

Through continuous technological advancements and a deep commitment to quality, we ensure that our green sand molding machines are among the most reliable and efficient on the market. Our systems help businesses reduce labor costs, increase operational efficiency, and improve overall casting quality, making us a trusted partner for companies worldwide.

Technical Specifications

Mold Size Range: 500x400mm to 1200x900mm

Production Capacity: 180-400 molds/hour

Mold Hardness: 90-95 HB

Operating Pressure: 0.5-0.8 MPa

Power Consumption: 30-75 kW

Sand Consumption: 0.06-0.3 m³/min

Key Advantages

Bidirectional sand shooting for perfect density distribution

Full automation with PLC control system

High-pressure injection for superior mold quality

Energy-efficient operation with low maintenance

IoT-ready for smart factory integration

Commitment to Innovation

As the casting industry evolves, so does JUNENG. We continuously monitor market trends and customer needs, adapting our solutions to meet the challenges of modern manufacturing. With strategic investments in research and development about sand green sand molding machines, we are poised to remain at the forefront of industry advancements, providing customers with state-of-the-art high pressure sand injection molding machine.

Conclusion

As a leading manufacturer of sand injection blow molding machine, JUNENG Machinery is dedicated to delivering world-class solutions that meet the evolving needs of the casting industry. With a commitment to quality, innovation, and customer satisfaction, we strive to remain the partner of choice for businesses looking to enhance their production capabilities and stay ahead in a competitive global market.

Our reputation for high-quality products and exceptional customer service has made us a preferred supplier for leading casting companies worldwide.