Product Features

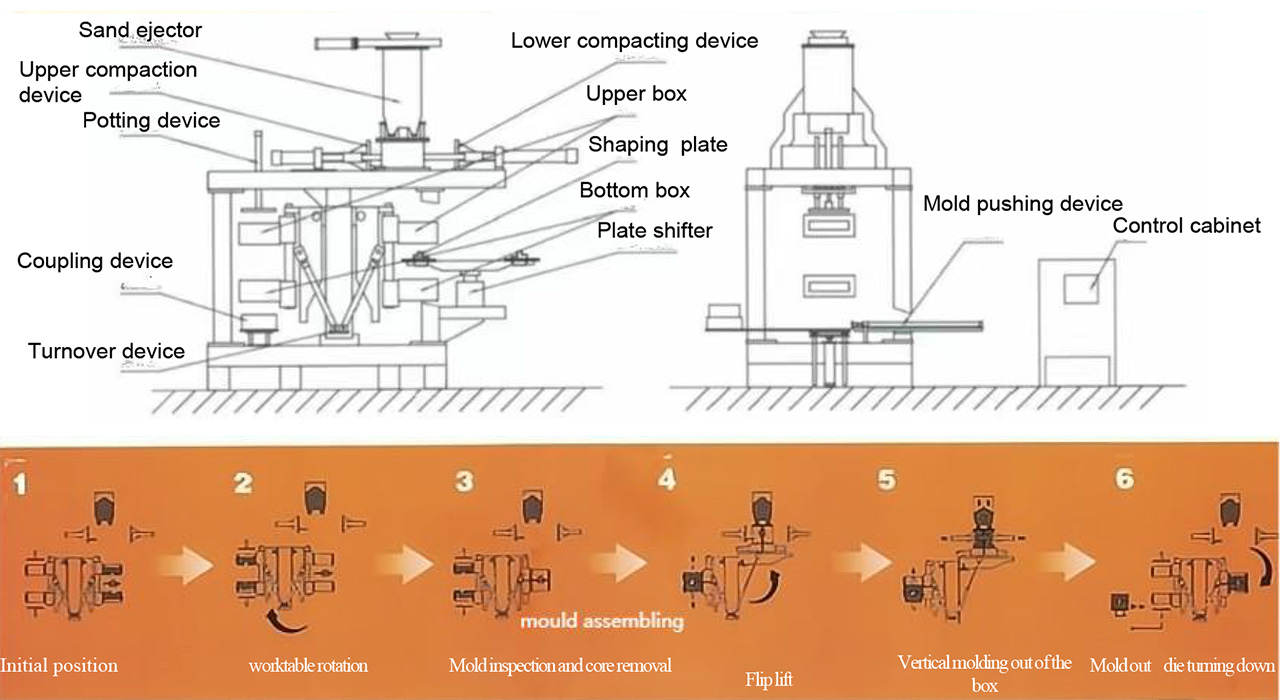

Double-station vertical sand injection and horizontal parting casting molding line

This is an automated molding equipment in casting production, with the following main features:

Dual-station: It features two independent working positions that can alternate for molding operations, enhancing production efficiency

Vertical sand shooting: Sand mold shooting is carried out in a vertical direction, ensuring high and uniform density of the sand mold

Horizontal parting: The parting surface of the sand mold is in a horizontal state, which is convenient for the joining of the upper and lower sand molds and the removal of parts

Application scenarios: Widely used in the batch production of small and medium-sized cast iron and cast steel parts in industries such as automobiles, machinery, and pipe fittings, it features high automation, stable molding quality, and high production efficiency

1. Double station molding and core at the same time, improve the sand mold output cycle rate.

2. Components are composed of imported OMRON,SRC, oil research and other high precision components, can effectively improve production efficiency, reduce the occurrence of faults.

3. According to the requirements of different sand mold thickness, the upper and lower compaction distance can be linearly adjusted.

Product Parameter

JN-AMF Foundry Moulding Line with Double Workstation Vertical Sand Shooting and Horizontal Parting

| Model | Mold Size | Mold Height from (Cope) | Mold Height to (Drag) | Average Maximum Mold Rate (without Core setting) | Molding System |

|---|---|---|---|---|---|

JN-AMF2 | 16" x 20" | 5" - 8" | 5" - 8" | 200 molds/hour | Aeration Sand Filling + Squeeze |

| 400 mm x 500 mm | 130 mm - 200 mm | 130 mm - 200 mm | 200 molds/hour (Including the 9sec core-setting time) | Aeration Sand Filling + Squeeze | |

JN-AMF3 | 20" X 24" (508 mm x 609.6 mm) | 5" - 8" | 5" - 8" | 200 molds/hour (Including the 9sec core-setting time) | Aeration Sand Filling + Squeeze |

| 500mm x 600mm | 130 mm - 200 mm | 130 mm - 200 mm | 200 molds/hour | Aeration Sand Filling + Squeeze | |

| 550 mm x 650mm | 130 mm - 200 mm | 130 mm - 200 mm | 200 molds/hour | Aeration Sand Filling + Squeeze | |

JN-AMF4 | 24" X 28" (609.6 mm x 711.2 mm) | 180 mm- 250 mm | 180 mm- 250 mm | 170 molds/hour | Aeration Sand Filling + Squeeze |

| 600 mm x 700 mm | 180 mm- 250 mm | 180 mm- 250 mm | 170 molds/hour | Aeration Sand Filling + Squeeze |

About Us

Founded on a foundation of excellence, JUNENG is dedicated to providing intelligent and cost-effective solutions to the casting industry. We are a high-tech research and development enterprise committed to advancing the field of flaskless Automatic moulding machine line . Our comprehensive range of products includes foundry molding equipment and fully integrated casting lines designed to meet the needs of small to medium-sized casting operations.

Among our flagship products, Our JN-FBO Vertical sand casting moulding machine with Horizontal Parting delivers high precision and efficiency for advanced casting applications. The JN-AMF Double Station Vertical sand moulding machine with Horizontal Parting enhances productivity with its dual-station design, delivering high-precision results. The JNH Top and Bottom moulding sander machine used in sand casting offers a versatile and cost-effective solution for various molding applications. And the JNP Horizontal Sand Shooting automatic sand moulding machine provides an economical option for simpler casting needs.

Through continuous technological advancements and a deep commitment to quality, we ensure that our high pressure moulding line foundry are among the most reliable and efficient on the market. Our systems help businesses reduce labor costs, increase operational efficiency, and improve overall casting quality, making us a trusted partner for companies worldwide.

Our Vision & Values

At JUNENG, our mission is clear: to lead the global foundry moulding line market through a relentless focus on quality, innovation, and customer satisfaction. We adhere to the core principles of “Market-driven, Quality-focused” in everything we do. By leveraging the latest technology, we consistently push the boundaries of what is possible in flaskless mold handling line. We aim to provide our customers with not only cutting-edge flaskless Automatic moulding machine line but also end-to-end solutions that enhance their production capabilities.

Commitment to Innovation

As the casting industry evolves, so does JUNENG. We continuously monitor market trends and customer needs, adapting our solutions to meet the challenges of modern manufacturing. With strategic investments in research and development about sand flaskless Automatic moulding machine line, we are poised to remain at the forefront of industry advancements, providing customers with state-of-the-art high pressure moulding line foundry that improve performance, reliability, and cost-efficiency.

Our Global Presence

JUNENG’s foundry moulding line are highly regarded not only in China but also in key markets around the world. Our flaskless mold handling line is utilized in industries ranging from automotive and aerospace to industrial manufacturing and construction. We continue to expand our presence globally, with active operations and partnerships in North America, South America, Europe, Southeast Asia, and beyond.

Conclusion

As a leading manufacturer of flaskless Automatic moulding machine line, JUNENG Machinery is dedicated to delivering world-class solutions that meet the evolving needs of the casting industry. With a commitment to quality, innovation, and customer satisfaction, we strive to remain the partner of choice for businesses looking to enhance their production capabilities and stay ahead in a competitive global market.

Our reputation for high-quality products and exceptional customer service has made us a preferred supplier for leading casting companies worldwide.

1. Integrated Double-Station Production System

Our Foundry Moulding Line revolutionizes casting efficiency with its synchronized Double Workstation design. Two fully independent moulding stations operate in parallel – while one completes sand shooting and compaction, the other simultaneously performs mould assembly or core setting. This continuous workflow boosts output by 90-110% and reduces cycle times by 50% versus single-station systems, delivering complete production-line solutions for high-volume foundries.

2. Precision Vertical Sand Shooting Technology

The line's core features advanced Vertical Sand Shooting systems injecting sand downward at 0.35-0.75 MPa pressure. Gravity-assisted compaction ensures uniform density distribution (hardness deviation ≤3%) across complex cavities. This eliminates air pockets while achieving consistent mould hardness of 88-93 (B-scale), producing castings with dimensional accuracy within ISO CT8-CT9 and surface finishes ≤Ra 12.5μm.

3. Ergonomic Horizontal Parting Operation

Engineered with Horizontal Parting technology, the system provides:

✓ Natural ergonomic access for core placement (up to 120kg) and inspection

✓ Eliminated flask deflection during pouring (supports castings ≤1,800kg)

✓ 35% faster mould transitions with automatic clamp release

✓ Integrated safety scanners meeting CE/OSHA standards

4. Intelligent Line Control & Flexibility

The fully automated Foundry Moulding Line includes:

◆ Pre-set programs for iron/steel/aluminum/copper alloys

◆ Real-time monitoring of 22+ parameters (sand density, temperature, cycle analytics)

◆ Compatibility with resin sand, green sand, and silicate binders

◆ Modular design allowing integration with pouring/cooling/conveyor systems