Product Features

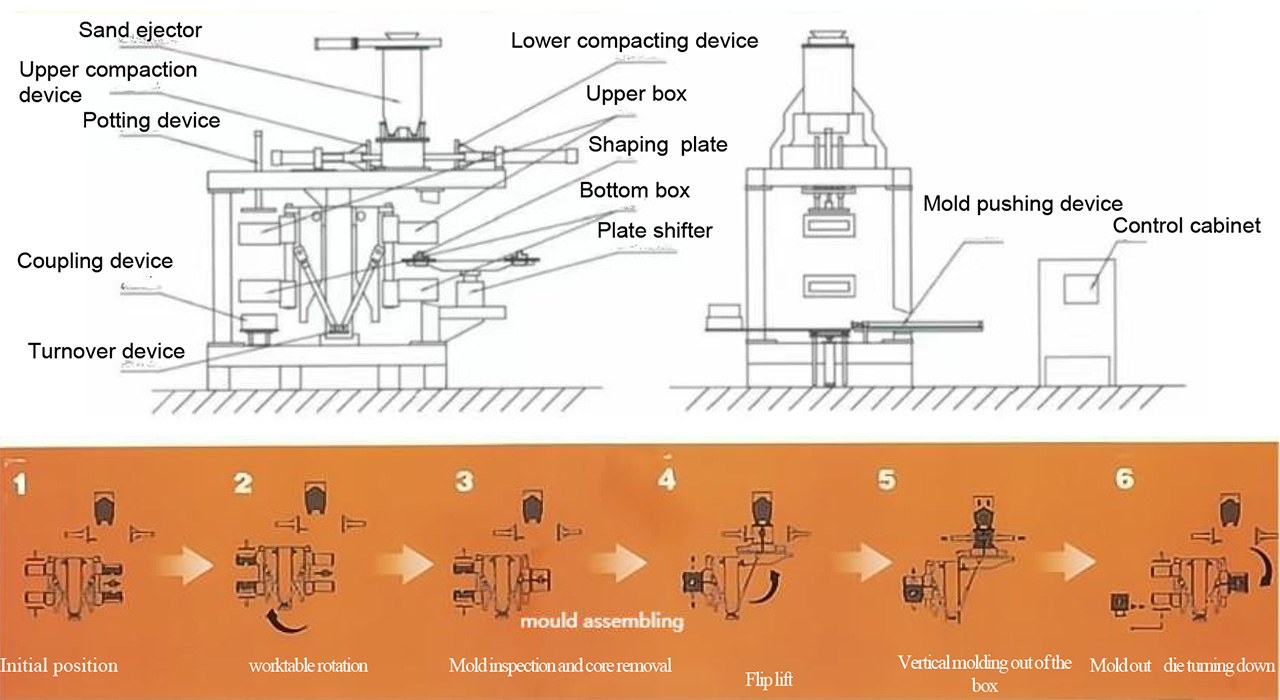

The JN-AMF Foundry Molding Machines with Double Workstation Vertical Sand Shooting and Horizontal Parting combines the benefits of vertical sand shooting, vertical molding, and horizontal parting into a single, efficient system. Designed with dual workstations, it enhances productivity by allowing alternating operations between two independent sets of sandboxes.

In operation, one set of sandboxes rotates 90 degrees upward to position beneath the sand shooting bucket. Sand is then shot vertically from above using compressed air, followed by hydraulic compaction to ensure mold integrity. After compaction, the sandbox returns to its horizontal position, and the mold is smoothly ejected onto the pouring cooling line. While one mold is being processed, the second set of sandboxes is prepared, allowing for continuous, alternating cycles that significantly boost production efficiency.

1. Innovative Dual-Station Vertical Sand Shooting Technology

Our Foundry Molding Machines with Double Workstation Vertical Sand Shooting and Horizontal Parting represent the pinnacle of foundry efficiency and precision. This advanced system features two independent workstations that operate simultaneously, doubling production capacity without increasing footprint. The vertical sand shooting technology ensures optimal sand density distribution by delivering sand perpendicular to the pattern plate, achieving 95-98% compaction efficiency. This dual-station design allows continuous production with one station loading/unloading while the other executes the shooting and compaction cycle, making it ideal for high-volume foundry operations requiring consistent, high-quality mold production.

2. Versatile Application Capability

Engineered for diverse foundry applications, this machine handles everything from small precision components to large industrial castings. The dual-station configuration supports different pattern sets simultaneously, enabling flexible production scheduling and rapid changeovers between jobs. The vertical shooting system accommodates various sand types including green sand, resin sand, and clay-bonded mixtures, while the horizontal parting mechanism ensures clean separation for all mold configurations. This versatility makes it suitable for automotive components, industrial machinery parts, pipe fittings, and architectural castings across both ferrous and non-ferrous foundries.

3. Fully Automated Dual-Station Operation

This automated foundry molding machine incorporates intelligent PLC control systems that synchronize both workstations for optimal performance. The automation includes robotic pattern changing, automatic sand level control, and real-time monitoring of shooting parameters. The dual-station design allows for production rates of 300-600 molds per hour, depending on mold size and complexity. The system features advanced sensors that monitor mold hardness (achieving 92-96 HB), shooting pressure (0.4-0.7 MPa), and parting force, ensuring consistent quality across both workstations with rejection rates below 0.3%.

4. Precision Horizontal Parting for Flawless Mold Separation

The horizontal parting system provides clean, precise mold separation with minimal pattern drag or mold damage. This technology ensures perfect alignment between cope and drag sections, maintaining dimensional accuracy within ±0.1mm tolerance. The dual-station configuration enables simultaneous parting operations, significantly reducing cycle times and increasing overall productivity by up to 60% compared to single-station machines. The horizontal parting mechanism is engineered for smooth operation with self-lubricating guides and hardened wear plates, ensuring long-term reliability and minimal maintenance requirements in continuous production environments.

5. Robust Construction and Energy-Efficient Design

Built for 24/7 operation, this machine features heavy-duty construction with reinforced steel frames, dual hydraulic systems, and wear-resistant components. The dual-station design incorporates energy-saving features such as variable displacement pumps, regenerative hydraulic circuits, and smart power management systems that reduce energy consumption by 35% compared to conventional machines. The enclosed shooting chambers contain sand and dust, while noise reduction technologies maintain operational levels below 75 dB. The machine's modular design allows easy access for maintenance and quick replacement of wear parts, ensuring maximum uptime and productivity.

Product Parameter

JN-AMF Foundry Molding Machines with Double Workstation Vertical Sand Shooting and Horizontal Parting

| Model | Mold Size | Mold Height from (Cope) | Mold Height to (Drag) | Average Maximum Mold Rate (without Core setting) | Molding System |

|---|---|---|---|---|---|

JN-AMF2 | 16" x 20" | 5" - 8" | 5" - 8" | 200 molds/hour | Aeration Sand Filling + Squeeze |

| 400 mm x 500 mm | 130 mm - 200 mm | 130 mm - 200 mm | 200 molds/hour (Including the 9sec core-setting time) | Aeration Sand Filling + Squeeze | |

JN-AMF3 | 20" X 24" (508 mm x 609.6 mm) | 5" - 8" | 5" - 8" | 200 molds/hour (Including the 9sec core-setting time) | Aeration Sand Filling + Squeeze |

| 500mm x 600mm | 130 mm - 200 mm | 130 mm - 200 mm | 200 molds/hour | Aeration Sand Filling + Squeeze | |

| 550 mm x 650mm | 130 mm - 200 mm | 130 mm - 200 mm | 200 molds/hour | Aeration Sand Filling + Squeeze | |

JN-AMF4 | 24" X 28" (609.6 mm x 711.2 mm) | 180 mm- 250 mm | 180 mm- 250 mm | 170 molds/hour | Aeration Sand Filling + Squeeze |

| 600 mm x 700 mm | 180 mm- 250 mm | 180 mm- 250 mm | 170 molds/hour | Aeration Sand Filling + Squeeze |

Company Profile

JUNENG Machinery Co., Ltd., founded in 2011, is a prominent player in the global foundry molding machines industry. As a subsidiary of Shengda Machinery Co., Ltd., JUNENG specializes in the development and production of cutting-edge foundry green sand automatic molding machine, and complete casting assembly lines. With a strong focus on innovation, JUNENG integrates advanced technology, high efficiency, and reliability into every product.

Our Vision & Values

At JUNENG, our mission is clear: to lead the global molding machine foundry market through a relentless focus on quality, innovation, and customer satisfaction. We adhere to the core principles of “Market-driven, Quality-focused” in everything we do. By leveraging the latest technology, we consistently push the boundaries of what is possible in sand molding machine foundry. We aim to provide our customers with not only cutting-edge foundry molding machines but also end-to-end solutions that enhance their production capabilities.

Global Reach & Industry Leadership

With a state-of-the-art manufacturing facility spanning over 10,000 square meters, JUNENG has firmly established itself as an industry leader. Our foundry green sand automatic molding machine are trusted by customers in over 20 countries, including the United States, Brazil, India, Russia, and Vietnam. Our global reach is further supported by a network of authorized agents and sales offices, ensuring that we can deliver localized service and technical support to all our international clients.

In addition to providing high-quality foundry moulding machines, JUNENG maintains a dedicated after-sales service system designed to offer timely technical support and assistance. Whether through direct service centers or our authorized partners, we are committed to creating lasting value for our customers and ensuring the seamless operation of their molding foundry machine.

Commitment to Innovation

As the casting industry evolves, so does JUNENG. We continuously monitor market trends and customer needs, adapting our solutions to meet the challenges of modern manufacturing. With strategic investments in research and development about sand molding machine foundry, we are poised to remain at the forefront of industry advancements, providing customers with state-of-the-art sand molding machine foundry that improve performance, reliability, and cost-efficiency.

Our Global Presence

JUNENG’s foundry molding machines are highly regarded not only in China but also in key markets around the world. Our foundry moulding machines is utilized in industries ranging from automotive and aerospace to industrial manufacturing and construction. We continue to expand our presence globally, with active operations and partnerships in North America, South America, Europe, Southeast Asia, and beyond.

Conclusion

As a leading manufacturer of molding foundry machine, JUNENG Machinery is dedicated to delivering world-class solutions that meet the evolving needs of the casting industry. With a commitment to quality, innovation, and customer satisfaction, we strive to remain the partner of choice for businesses looking to enhance their production capabilities and stay ahead in a competitive global market.

Our reputation for high-quality products and exceptional customer service has made us a preferred supplier for leading casting companies worldwide.

Dual-Station Production Revolution

Our advanced Foundry Molding Machines feature a groundbreaking Double Workstation design that redefines manufacturing efficiency. Two independent stations operate concurrently - while one completes sand shooting and compaction, the other simultaneously executes mold assembly or core setting. This parallel processing reduces cycle times by 45-60% and boosts output capacity by 80-100% compared to single-station systems, delivering maximum ROI for high-volume foundries.

Precision Vertical Sand Shooting Technology

Engineered with Vertical Sand Shooting systems, these Foundry Molding Machines ensure superior mold integrity. High-pressure sand is injected downward with controlled force (0.3-0.7 MPa), leveraging gravity for uniform density distribution. This eliminates density gradients in complex geometries, achieving consistent hardness (85-92 B-scale) across cavities. Resultant castings maintain dimensional accuracy within ISO CT8-9 tolerances with surface finishes ≤ Ra 12.5μm.

Ergonomic Horizontal Parting System

The Horizontal Parting mechanism enhances operational safety and efficiency. Molds split along a horizontal plane, providing:

✓ Optimal ergonomic access for core placement and inspection

✓ Enhanced stability for heavy castings (up to 1,500kg)

✓ 30% faster mold-change capability with quick-release clamps

✓ Integrated safety interlocks and hydraulic guarding for OSHA compliance

Intelligent Control & Material Versatility

A Siemens PLC-based control center with 10" HMI offers:

◆ Pre-loaded programs for iron, steel, aluminum, and copper alloys

◆ Real-time monitoring of 18+ parameters (compaction force, sand density, cycle timing)

◆ Compatibility with resin-coated sand, green sand, and cold-box binders

◆ Capacity for molds up to 1.5m x 1.2m x 0.6m - ideal for automotive brake components, valve bodies, and hydraulic manifolds

Total Cost of Ownership Advantage

These Foundry Molding Machines deliver unparalleled value:

● Energy Efficiency: Dual-station power optimization cuts kWh/ton by 40%

● Waste Reduction: ≤1.5% scrap rate through consistent mold quality

● Low Maintenance: Sealed hydraulic circuits and quick-change wear parts

● ROI Acceleration: Payback achieved in 12-16 months via 24/7 production capability