Product Features

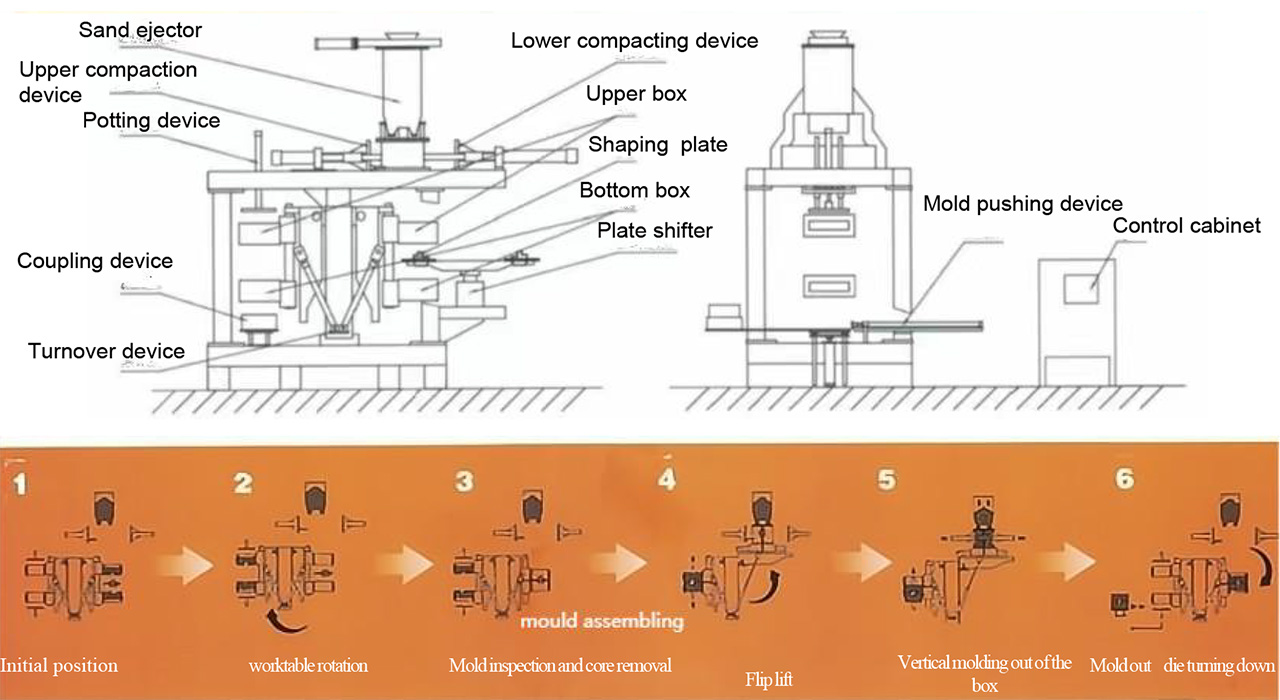

The JNP Horizontal Parting Flaskless Moulding Machines is a high-performance, servo-driven molding system designed for stable operation, minimal energy consumption, and consistent casting quality. Featuring a horizontal sand shooting mechanism and a servo-controlled hydraulic system, the JNP series offers a reliable solution for foundries seeking high automation, low labor requirements, and efficient production.

Engineered for durability and precision, the JNP series supports adjustable molding parameters to meet the varying needs of different casting applications. The system includes self-diagnostic capabilities for quick fault detection and maintenance, while the air-cooled temperature control system ensures efficient, quiet operation with reduced energy consumption.

The JNP series combines operational simplicity with advanced automation to help foundries optimize productivity while maintaining excellent casting quality.

Product Features

1. Servo-Controlled Horizontal Sand Shooting – The horizontal shooting design ensures accurate and consistent mold filling, making it suitable for a wide range of casting shapes and sizes.

2. Stable Performance & Long Service Life – Built with high-quality components and a robust mechanical structure, the machine delivers long-term, reliable performance under continuous operation.

3. Low Labor Requirements – The automated control system and simplified operation reduce the need for skilled labor, lowering operational costs.

4. Flexible Parameter Adjustment – Key settings such as mold compaction force, shooting speed, and cycle time can be adjusted to meet specific casting process requirements, improving output efficiency.

5. Imported Servo Hydraulic System – The system ensures precise control with low noise and includes an air-cooled temperature regulation feature for improved energy efficiency and environmental performance.

6. Self-Diagnostic Functionality – Built-in fault detection and monitoring capabilities help identify issues quickly, reducing downtime and simplifying maintenance.

7. High Degree of Automation – From sand shooting to mold ejection, the process is highly automated, minimizing human intervention and improving consistency.

1. Flaskless Design Maximizes Efficiency

Our Flaskless Moulding Machines with Horizontal Sand Shooting eliminate traditional flask handling, slashing production time by 50%. Sand molds are directly formed, cured, and ejected without flasks, enabling continuous high-speed production. This reduces labor costs and floor space requirements while achieving 300+ molds/hour output.

2. Precision Horizontal Sand Shooting Technology

Engineered with advanced horizontal sand shooting, the machine propels sand uniformly into patterns at controlled pressure (0.3-0.6 MPa). This ensures optimal density distribution (>90% compaction), flawless surface reproduction, and zero voids – ideal for complex geometries like engine blocks or valve housings.

3. Automated Turnkey Operation

Fully automated PLC-controlled cycles integrate sand filling, horizontal shooting, compaction, and mold ejection. Operators manage production via touchscreen HMI with real-time diagnostics. Compatible with green sand, resin sand, and silicate-bonded systems, reducing changeover time to <15 minutes.

4. Unmatched Quality & Consistency

Horizontal sand shooting delivers 30% higher mold hardness (90-95 HB) vs. vertical methods. Flaskless technology maintains dimensional accuracy (±0.3mm tolerance) and reduces casting defects like sand inclusion by 40%. Dual-side simultaneous compaction ensures perfect mold integrity.

5. Cost-Saving Industrial Design

No Flask Investment: Saves $50k–$200k annually in flask maintenance

Energy Efficient: 25% lower power consumption with servo-driven systems

Minimal Waste: 98% sand reclamation rate

Compact Footprint: 30% smaller than flask-type machines

Low Maintenance: Sealed hydraulic units and wear-resistant shooting nozzles

Technical Specifications:

Molding Speed: 120–320 molds/hour

Mold Size Range: 500x400mm to 1200x900mm

Sand Capacity: 0.03–0.25 m³/min

Power: 25–75 kW

Applications: Automotive brake discs, pump impellers, gearbox casings, and high-precision industrial castings.

Why Choose Our Machine?

✅ Flaskless + Horizontal Shooting = 60% Lower Operating Costs

✅ Industry-Leading 0.5% Rejection Rate

✅ IoT-Ready for Smart Foundry Integration

✅ 24/7 Reliability with <1% Downtime

Product Parameter

JNP Horizontal Parting Flaskless Moulding Machines

| Model | Mold Size | Mold Height from (Cope) | Mold Height to (Drag) | Average Maximum Mold Rate (without Core setting) | Molding System |

|---|---|---|---|---|---|

| JNP3545 | (300~380)*(400~480)mm | 130~250mm | 130~250mm | 26 seconds/mold (without core-setting time) | Edge Blow + Squeeze |

| JNP4555 | (400~480)*(500~580)mm | 130~250mm | 130~250mm | 26 seconds/mold (without core-setting time) | Edge Blow + Squeeze |

JNP5565 | (500~580)*(600~680)mm | 130~250mm | 130~250mm | 26 seconds/mold (without core-setting time) | Edge Blow + Squeeze |

JNP6575 | (600~680)*(700~780)m | 130~250mm | 130~250mm | 26 seconds/mold (without core-setting time) | Edge Blow + Squeeze |

JNP7585 | (700~780)*(800~880)mm | 130~250mm | 130~250mm | 26 seconds/mold (without core-setting time) | Edge Blow + Squeeze |

Company Profile

JUNENG Machinery Co., Ltd., founded in 2011, is a prominent player in the global flaskless mold handling line industry. As a subsidiary of Shengda Machinery Co., Ltd., JUNENG specializes in the development and production of cutting-edge horizontal flaskless moulding machines, and complete casting assembly lines. With a strong focus on innovation, JUNENG integrates advanced technology, high efficiency, and reliability into every product.

About Us

Founded on a foundation of excellence, JUNENG is dedicated to providing intelligent and cost-effective solutions to the casting industry. We are a high-tech research and development enterprise committed to advancing the field of horizontal Parting Flaskless moulding machines . Our comprehensive range of products includes automated automatic horizontal flaskless moulding machines and fully integrated casting lines designed to meet the needs of small to medium-sized casting operations.

Among our flagship products, Our JN-FBO Vertical sand casting molding machines and Horizontal Parting delivers high precision and efficiency for advanced casting applications. The JN-AMF Double Station Vertical sand casting molding machinery and Horizontal Parting enhances productivity with its dual-station design, delivering high-precision results. The JNH Top and Bottom sand moulding machinery used in sand casting offers a versatile and cost-effective solution for various molding applications. And the JNP Horizontal electric sand injection molding machine provides an economical option for simpler casting needs.

Through continuous technological advancements and a deep commitment to quality, we ensure that our horizontal Parting Flaskless moulding Casting machines are among the most reliable and efficient on the market. Our systems help businesses reduce labor costs, increase operational efficiency, and improve overall casting quality, making us a trusted partner for companies worldwide.

Our Vision & Values

At JUNENG, our mission is clear: to lead the global flaskless moulding machines market through a relentless focus on quality, innovation, and customer satisfaction. We adhere to the core principles of “Market-driven, Quality-focused” in everything we do. By leveraging the latest technology, we consistently push the boundaries of what is possible in flaskless mold handling line sand automation. We aim to provide our customers with not only cutting-edge horizontal flaskless moulding machines but also end-to-end solutions that enhance their production capabilities.

Global Reach & Industry Leadership

With a state-of-the-art manufacturing facility spanning over 10,000 square meters, JUNENG has firmly established itself as an industry leader. Our horizontal Parting Flaskless moulding machines are trusted by customers in over 20 countries, including the United States, Brazil, India, Russia, and Vietnam. Our global reach is further supported by a network of authorized agents and sales offices, ensuring that we can deliver localized service and technical support to all our international clients.

In addition to providing high-quality automatic horizontal flaskless moulding machines , JUNENG maintains a dedicated after-sales service system designed to offer timely technical support and assistance. Whether through direct service centers or our authorized partners, we are committed to creating lasting value for our customers and ensuring the seamless operation of their horizontal Parting Flaskless moulding Casting machines.

Commitment to Innovation

As the casting industry evolves, so does JUNENG. We continuously monitor market trends and customer needs, adapting our solutions to meet the challenges of modern manufacturing. With strategic investments in research and development about sand flaskless moulding machines, we are poised to remain at the forefront of industry advancements, providing customers with state-of-the-art flaskless mold handling line that improve performance, reliability, and cost-efficiency.

Our Global Presence

JUNENG’s horizontal flaskless moulding machines are highly regarded not only in China but also in key markets around the world. Our horizontal Parting Flaskless moulding machines is utilized in industries ranging from automotive and aerospace to industrial manufacturing and construction. We continue to expand our presence globally, with active operations and partnerships in North America, South America, Europe, Southeast Asia, and beyond.

Conclusion

As a leading manufacturer of automatic horizontal flaskless moulding machines, JUNENG Machinery is dedicated to delivering world-class solutions that meet the evolving needs of the casting industry. With a commitment to quality, innovation, and customer satisfaction, we strive to remain the partner of choice for businesses looking to enhance their production capabilities and stay ahead in a competitive global market.

Our reputation for high-quality products and exceptional customer service has made us a preferred supplier for leading casting companies worldwide.