Product Features

The JN-AMF Double Workstation Vertical Sand Moulding Machine with Horizontal Parting combines the benefits of vertical sand shooting, vertical molding, and horizontal parting into a single, efficient system. Designed with dual workstations, it enhances productivity by allowing alternating operations between two independent sets of sandboxes.

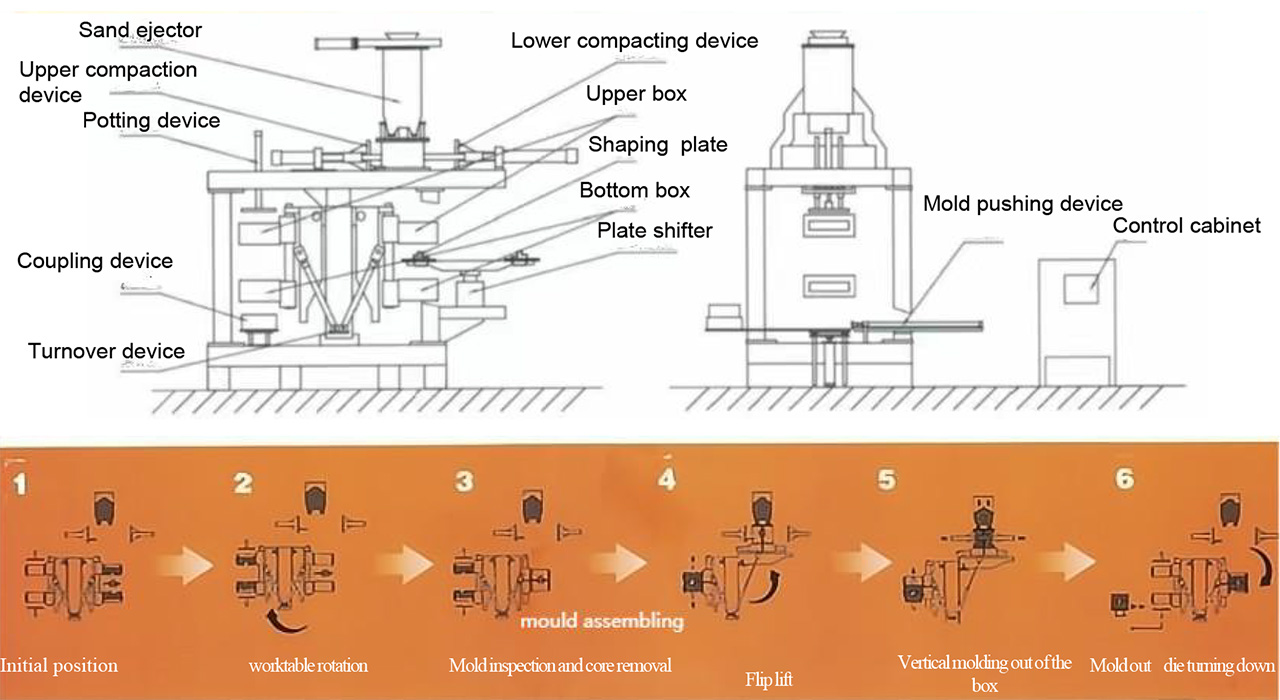

In operation, one set of sandboxes rotates 90 degrees upward to position beneath the sand shooting bucket. Sand is then shot vertically from above using compressed air, followed by hydraulic compaction to ensure mold integrity. After compaction, the sandbox returns to its horizontal position, and the mold is smoothly ejected onto the pouring cooling line. While one mold is being processed, the second set of sandboxes is prepared, allowing for continuous, alternating cycles that significantly boost production efficiency.

Product Features

1. Dual Workstation Design – Alternating operations between two independent sets of sandboxes enable continuous molding cycles, enhancing productivity.

2. Vertical Sand Shooting– The 90-degree rotation positions the sandbox for vertical sand shooting from above, ensuring optimal sand filling and mold compaction.

3. Horizontal Parting and Mold Ejection – Post-compaction, the sandbox returns to a horizontal position, facilitating smooth mold ejection and preparation for pouring.

4. Adjustable Mold Height and Sand Volume – Operators can fine-tune mold height and sand volume through the human-machine interface, optimizing material usage and reducing production costs.

5. Precise Compaction Control – The hydraulic system allows for stepless adjustment of compaction pressure, ensuring consistent mold quality.

6. High Precision in Sandbox Alignment – The system ensures accurate alignment during sandbox closing and opening, maintaining mold integrity.

7. Efficient Mold Changeover – The design facilitates easy mold plate changes, allowing the reuse of existing templates and minimizing downtime.

8. Integrated Fault Detection – The machine features a fault indication system, simplifying troubleshooting and maintenance.

Innovative Dual-Station Design with Vertical Molding & Horizontal Parting

Our Double Workstation Vertical Sand Moulding Machine and Horizontal Parting system represents the pinnacle of foundry efficiency, combining dual-station operation with advanced vertical molding and precision horizontal parting technologies. This innovative configuration enables simultaneous processing at two independent workstations, effectively doubling production capacity while maintaining a compact footprint. The vertical molding system ensures optimal sand density distribution through perpendicular sand delivery, achieving 94-98% compaction efficiency, while the horizontal parting mechanism provides clean, precise mold separation with minimal pattern drag. This integrated approach makes our system superior to conventional sand casting moulding machine options, delivering unmatched productivity for high-volume foundry operations.

Automated Precision for Clay Sand and Green Sand Applications

Engineered as an advanced automatic sand moulding machine, this system excels in handling various sand types including clay-bonded mixtures and green sand formulations. The dual-station design incorporates intelligent moisture control systems that maintain optimal sand conditions throughout the production process. As a specialized clay sand moulding machine, it features automated water addition and mixing mechanisms that ensure consistent binder activation and perfect moisture distribution. The PLC-controlled automation manages both workstations simultaneously, coordinating vertical shooting, compaction, and horizontal parting operations with precision accuracy, achieving production rates of 300-600 molds per hour while maintaining dimensional tolerances within ±0.15mm.

Enhanced Productivity Through Dual-Station Operation

This revolutionary automatic sand moulding machine doubles output without doubling space requirements or energy consumption. The dual-station design allows continuous production with one station performing sand shooting and compaction while the other executes mold ejection and pattern preparation. This efficient workflow eliminates idle time and maximizes equipment utilization. The system incorporates principles similar to sand slinger moulding machine technology in its material handling efficiency, while offering superior precision through controlled vertical shooting. This configuration reduces labor requirements by 70% compared to single-station machines while increasing overall production capacity by 90-100%, delivering exceptional return on investment for high-volume foundries.

Product Parameter

JN-AMF Double Workstation Vertical Sand Moulding Machine and Horizontal Parting

| Model | Mold Size | Mold Height from (Cope) | Mold Height to (Drag) | Average Maximum Mold Rate (without Core setting) | Molding System |

|---|---|---|---|---|---|

JN-AMF2 | 16" x 20" | 5" - 8" | 5" - 8" | 200 molds/hour | Aeration Sand Filling + Squeeze |

| 400 mm x 500 mm | 130 mm - 200 mm | 130 mm - 200 mm | 200 molds/hour (Including the 9sec core-setting time) | Aeration Sand Filling + Squeeze | |

JN-AMF3 | 20" X 24" (508 mm x 609.6 mm) | 5" - 8" | 5" - 8" | 200 molds/hour (Including the 9sec core-setting time) | Aeration Sand Filling + Squeeze |

| 500mm x 600mm | 130 mm - 200 mm | 130 mm - 200 mm | 200 molds/hour | Aeration Sand Filling + Squeeze | |

| 550 mm x 650mm | 130 mm - 200 mm | 130 mm - 200 mm | 200 molds/hour | Aeration Sand Filling + Squeeze | |

JN-AMF4 | 24" X 28" (609.6 mm x 711.2 mm) | 180 mm- 250 mm | 180 mm- 250 mm | 170 molds/hour | Aeration Sand Filling + Squeeze |

| 600 mm x 700 mm | 180 mm- 250 mm | 180 mm- 250 mm | 170 molds/hour | Aeration Sand Filling + Squeeze |

Company Profile

JUNENG Machinery Co., Ltd., founded in 2011, is a prominent player in the global moulding sander machine industry. As a subsidiary of Shengda Machinery Co., Ltd., JUNENG specializes in the development and production of cutting-edge moulding sander machine,vertical automatic sand moulding machine, and complete casting assembly lines. With a strong focus on innovation, JUNENG integrates advanced technology, high efficiency, and reliability into every product.

Global Reach & Industry Leadership

With a state-of-the-art manufacturing facility spanning over 10,000 square meters, JUNENG has firmly established itself as an industry leader. Our automatic sand moulding machine are trusted by customers in over 20 countries, including the United States, Brazil, India, Russia, and Vietnam. Our global reach is further supported by a network of authorized agents and sales offices, ensuring that we can deliver localized service and technical support to all our international clients.

In addition to providing high-quality clay sand moulding machine, JUNENG maintains a dedicated after-sales service system designed to offer timely technical support and assistance. Whether through direct service centers or our authorized partners, we are committed to creating lasting value for our customers and ensuring the seamless operation of their sand casting moulding machine.

Commitment to Innovation

As the casting industry evolves, so does JUNENG. We continuously monitor market trends and customer needs, adapting our solutions to meet the challenges of modern manufacturing. With strategic investments in research and development about sand sand moulding machine, we are poised to remain at the forefront of industry advancements, providing customers with state-of-the-art moulding sander machine that improve performance, reliability, and cost-efficiency.

Our Global Presence

JUNENG’s automatic sand moulding machine are highly regarded not only in China but also in key markets around the world. Our clay sand moulding machine is utilized in industries ranging from automotive and aerospace to industrial manufacturing and construction. We continue to expand our presence globally, with active operations and partnerships in North America, South America, Europe, Southeast Asia, and beyond.

Conclusion

As a leading manufacturer of sand casting moulding machine , JUNENG Machinery is dedicated to delivering world-class solutions that meet the evolving needs of the casting industry. With a commitment to quality, innovation, and customer satisfaction, we strive to remain the partner of choice for businesses looking to enhance their production capabilities and stay ahead in a competitive global market.

Our reputation for high-quality products and exceptional customer service has made us a preferred supplier for leading casting companies worldwide.