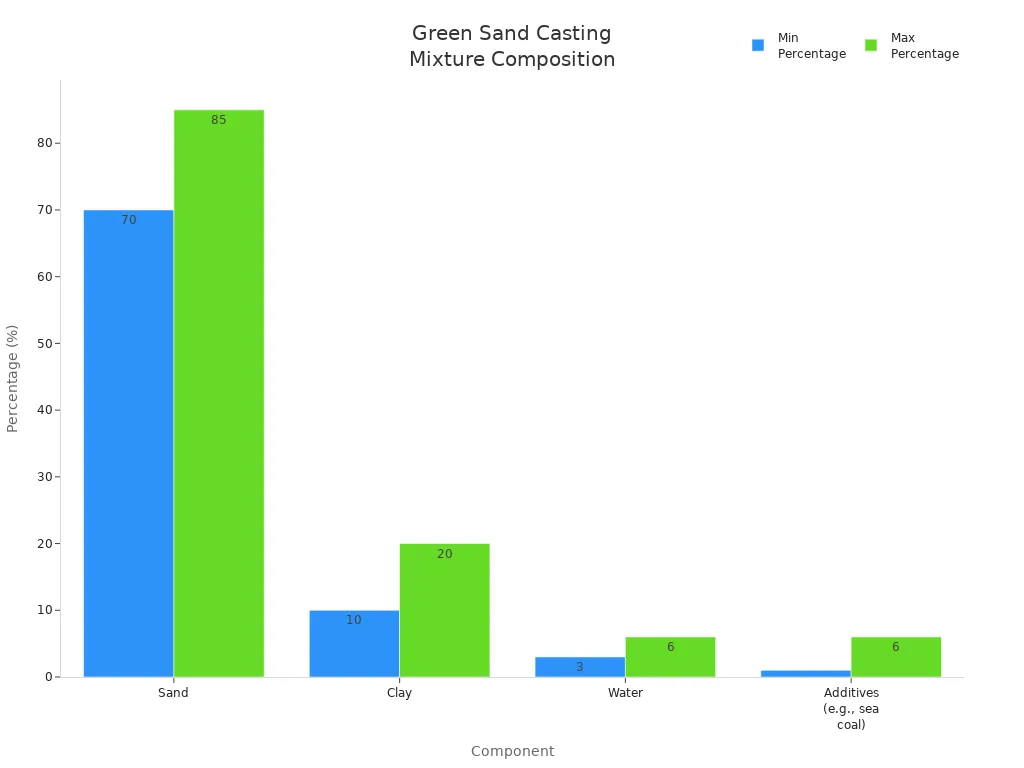

ou use five main materials in green sand casting. These are silica sand, bentonite clay, water, powdered coal (sea coal), and additives. Each material has a special job. They help shape the mold and affect the casting. Look at the table below to see their usual amounts and what they do:

You will learn how each material changes mold strength. You will also see how they change the surface and quality of the casting in the next parts.

Key Takeaways

Green sand casting uses five main materials. These are silica sand, bentonite clay, water, powdered coal, and additives.

Silica sand is very important for mold strength and shape. It makes up 85-90% of the mix.

Bentonite clay works as a binder. It holds the sand grains together. It also helps the mold stay strong.

Water is needed to make the binder work. It keeps the mold flexible and strong.

Powdered coal helps the surface look smooth. It also lowers defects by making a protective layer during casting.

Additives help change the sand mix for different metals. They also improve the quality of the casting.

The right amount of each material is very important. This helps make strong molds and good castings.

Good sand casting machines, like those from Quanzhou Juneng Machinery, give steady results.

1. Silica Sand

Silica sand is the main material in green sand casting. It makes up about 75% to 85% of the mix. This large amount shows how important silica sand is for the mold.

Role in Green Sand Casting

Mold Structure

You use silica sand to build the mold. The grains fit together tightly. This gives the mold strength and keeps it stable. Silica sand can handle high heat from melted metal. It does not break down when it gets hot. This keeps the mold strong during casting.

Tip: Check the grain size of your silica sand. Finer grains make smoother surfaces. Coarser grains help gases escape.

Here is a table that shows how silica sand helps the mold:

Surface Finish

Silica sand changes how the casting looks on the outside. The size and spread of the grains decide if the surface is smooth or rough. Fine silica sand gives a better finish. This is important for parts that need to fit well.

Why Silica Sand

High Quality

You pick silica sand because it is strong and lets air pass through. It also stays stable when hot. These things help stop problems like holes and cracks. Silica sand lets gases out during casting. This keeps your part free from bubbles.

Here is a table that compares silica sand to other sands:

Cost-Effective

Silica sand is cheap and easy to get. You can use it again and again. This saves money when making parts. Most sand casting machines work best with good silica sand. This helps you get the same good results each time.

Note: Using silica sand saves money and makes better castings.

Silica sand is special because it makes strong molds and smooth surfaces. It also helps stop mistakes. Picking the right silica sand helps you do well in every casting job.

2. Bentonite Clay

Bentonite clay is very important in green sand casting. It acts as a binder and makes up about 5% to 11% of the mix. This clay helps the sand grains stick together. It gives the mold its strength.

Binder Function

Mold Strength

Bentonite clay covers each sand grain with a sticky layer. This sticky layer helps the grains stay together. The mold walls become strong. When you pour hot metal, the mold keeps its shape. It does not fall apart. Bentonite clay has montmorillonite inside. Montmorillonite soaks up water and makes the clay stickier. This gives you a tough mold that can handle casting pressure.

Bentonite clay makes a sticky layer on sand grains.

Montmorillonite soaks up water and makes it stronger.

The clay changes when it gets hot, which changes how it sticks.

Mold Integrity

You need the mold to stay together for good castings. Bentonite clay keeps the mold whole during pouring and cooling. It stops the mold from breaking. This gives you sharp edges and clear details. When the temperature goes over 600 °C, bentonite loses its stickiness and becomes dead clay. This helps stop the sand from expanding too much. The mold keeps its shape better.

Tip: Always check the water in your sand mix. Too much or too little water can make the mold weak.

Importance in Green Sand Casting

Easy Breakdown

After casting, you want to take out the part easily. Bentonite clay helps the mold break apart without sticking to the metal. You use less water with bentonite than with other clays. This keeps the sand loose and easy to reuse. It saves you time and work when cleaning up.

Enhances Properties

You pick bentonite clay because it makes the mold better. It helps the sand flow well and gives strong molds. It also gives high strength when hot or dry. Sodium bentonite is best for strong molds. You get the best results with more than 70% montmorillonite. Bentonite clay works well with carbonaceous materials. These help make the surface smooth and stop wetting.

You see bentonite clay in most sand casting machines. Brands like Quanzhou Juneng Machinery use it. This clay helps you get the same good results every time.

Note: Bentonite clay gives you strong molds, easy cleanup, and better castings. You can count on it every time you use it in green sand casting.

3. Water

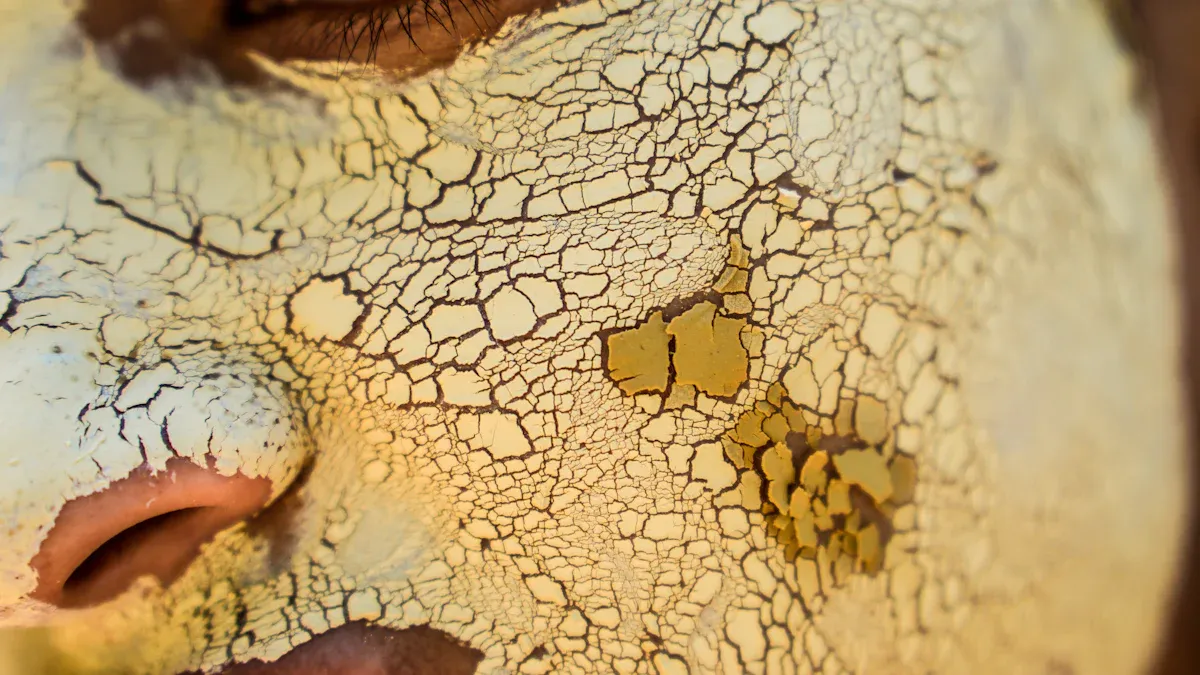

Water is very important in green sand casting. You usually add 2% to 4% water to the sand mix. This small amount changes how the mold works and how your casting looks. The name "green sand" means the mold is wet, not green in color. Like green wood, green sand has moisture. This moisture is needed for the mold to work well during casting.

Activates Binder

Water makes bentonite clay work in the sand mix. Without water, clay cannot hold the sand grains together. When you add water, clay swells and covers each grain. This makes the mold strong and flexible.

Moisture Content

You must watch the moisture level closely. Here are some important facts:

Most green sand casting mixes have about 4% water.

Water makes the mold stronger and lets air pass through.

Too much water can cause problems like holes or weak molds.

Tip: Always check your water amount. Even a small change can change how the mold works.

Plasticity

Water makes the sand mix easy to shape and pack. When water touches the cations in bentonite clay, the clay swells and gets sticky. This swelling helps sand grains stick together and makes the mold easier to use.

Water hydrates cations like sodium, calcium, and magnesium in clay.

Hydration makes clay layers swell and move apart.

Swelling helps bind sand grains and makes the mold more flexible.

Effects on Green Sand Casting

Water changes every part of the casting process. The right amount helps the mold keep its shape and lets you remove the casting easily.

Mold Quality

You want your mold to be strong and tight. The best moisture level (about 34%–38% for full bentonite wetting) gives the sand mix good wet strength. If you use too little water, the mold gets weak and may break. If you use too much water, the mold loses strength and may get surface problems.

The right moisture makes strong, tight molds.

Not enough water makes weak molds and problems like sand eyes.

Too much water lowers strength and causes gas flaws.

Casting Results

Water amount affects your casting results. Good moisture helps the mold let out gases and stops surface problems. If you use water with salts, the mold’s wet strength drops. Distilled water gives better results.

Note: Always use clean water in your sand casting equipment. This helps you get good, steady castings, especially with brands like Quanzhou Juneng Machinery.

Water is needed to make the binder work, shape the mold, and help your green sand casting succeed.

4. Powdered Coal/Sea Coal

Powdered coal is also called sea coal. It is very important in green sand casting. You usually add about 3% to 5% to the sand mix. Even a small amount can change how your castings turn out.

Surface Finish

Adding powdered coal or sea coal helps the surface look better. The coal dust makes a layer between the hot metal and the sand. This layer helps stop common problems on the surface.

Reduces Defects

You want your finished parts to have fewer problems. Powdered coal helps by making a thin carbon layer when it gets hot. This layer protects the casting from burning. It also stops sand from sticking to the metal. Your casting comes out cleaner. It lowers the chance of burned-on spots and iron oxide.

Tip: Finer coal dust makes the surface smoother. But it also lets more air through. You need to pick the right size for the best results.

Improves Quality

You get better castings when you use powdered coal. The gas from sea coal keeps sand from sticking to the part. This means you do not need to clean or fix the part as much. Your parts look better and need less work after casting.

Why Add Coal

There are many reasons to add coal to your sand mix. It does more than just help the surface.

Enhances Mold Properties

Powdered coal and other additives make a special air inside the mold. This stops bad chemical changes that can hurt your casting. Anthracite coal is better for the environment than bituminous coal. It makes less pollution. It also helps stop the casting surface from getting wet.

Here is a table that shows the usual amounts in green sand casting:

You can use other carbon materials too. Gilsonite makes the mold harder and the sand tighter. Corn flour helps the mold break apart after casting. Dextrin makes the mold stronger when dry. These additives work together to make strong molds.

Typical Percentage

You should keep powdered coal or sea coal at 3% to 5%. Too much can make more gas and more pollution. Anthracite coal is a good choice for sand casting. It helps stop problems and makes the surface better. Many foundries, like those using Quanzhou Juneng Machinery, use anthracite for better results and less pollution.

Note: Always check how much additive you use. The right mix gives you better castings and a safer place to work.

Powdered coal or sea coal is needed for good green sand casting. It helps you get smooth surfaces, strong molds, and fewer problems.

5. Additives

Additives are very important in green sand casting. You use them to make the mold better and get good castings. These materials let you change the sand mix for different metals and needs.

Types of Additives

Organic Materials

You often put organic materials in your sand mix. Some examples are wood flour, corn flour, and dextrin. Each one helps in a special way. Wood flour makes the mold break apart easily after casting. Corn flour helps the mold fall apart and makes cleaning faster. Dextrin makes the mold stronger when dry and helps it keep its shape.

Organic additives also help the environment. You can use plant-based materials to lower bad emissions from man-made binders.

Custom Properties

You pick additives for the results you want in your casting. Some common ones are graphite powder for smoother surfaces. Brown iron oxide helps the mold stick together and stops sand burning. Sodium bentonite gives extra strength to the mold. Sawdust makes the mold harder and less rough.

Here is a table that shows what each additive does:

Purpose in Green Sand Casting

Enhances Mixture

Additives make your sand mix stronger and easier to use. For example, graphite powder helps you get smooth surfaces every time. Brown iron oxide and sawdust make cast parts tougher. These materials help you get fewer mistakes and better castings.

Tip: Always pick additives that match the metal you use. Aluminum needs finer sand and special additives for good results. Iron castings work better with rougher sand and more sea coal.

Special Applications

You use additives for special casting jobs. Sea coal, starch, and wood flour help you get smoother surfaces and fewer problems. Gilsonite and silica flour stop sand from sticking and make the mold denser. You can change your sand mix for different metals and shapes.

When you use sand casting machines, make sure your additives work well with them. Brands like Quanzhou Juneng Machinery have equipment that mixes additives evenly and keeps mold quality high. This helps you get the same good results every time.

Note: The right additives help you meet your project goals and make every part of green sand casting better.

You need five main materials for green sand casting. These help you make strong molds and good castings.

Silica sand gives the mold its shape.

Bentonite clay holds the mold together.

Water helps the clay work and keeps things flexible.

Powdered coal makes the surface smooth and stops mistakes.

Additives change how strong the mold is and how air moves through.

Using the right amounts of each material is important. This helps the mold stay strong, lets air out, and makes it easy to break apart. If you use good sand casting machines, like ones from Quanzhou Juneng Machinery, you will get great results every time.

FAQ

What is the main purpose of silica sand in green sand casting?

Silica sand helps the mold keep its shape. It makes the mold strong. You get a smooth finish on your casting. Most machines use silica sand for good results.

Why do you need bentonite clay in the sand mix?

Bentonite clay sticks sand grains together. It helps the mold stay strong when casting. Quanzhou Juneng Machinery says bentonite makes better molds.

How does water affect green sand casting?

Water makes the clay binder work. The right amount keeps the mold flexible and strong. Too much or too little water can cause problems in your casting.

What does powdered coal or sea coal do in the mixture?

Powdered coal helps the surface look smooth. It lowers mistakes like rough spots. When you pour hot metal, it forms a shield.

Which additives can you use for special casting needs?

You can add wood flour, corn flour, or dextrin. These help the mold break apart and make castings better. Some machines mix additives for you.

Can you reuse green sand after casting?

Yes, you can use green sand again and again. You must check moisture and binder levels. Quanzhou Juneng Machinery has machines to recycle sand well.

How do you choose the right sand casting equipment?

Pick equipment that mixes materials evenly and controls moisture. Quanzhou Juneng Machinery gives you reliable machines for steady results.

What problems can happen if you use the wrong material proportions?

You might get weak molds or rough surfaces. Casting defects can happen too. Always measure your materials right. Good machines help keep the mix correct.