A sand casting machine shapes sand molds to form metal casting parts. You rely on the right machine to boost production efficiency and casting quality. Picking the correct model matters because each sand casting machine—manual, semi-automatic, automatic, servo molding, flask molding, or core-making—fits different production needs. Quanzhou Juneng Machinery offers advanced options that help you match machine type to your casting complexity and material. Check the table below to see how different factors affect your results:

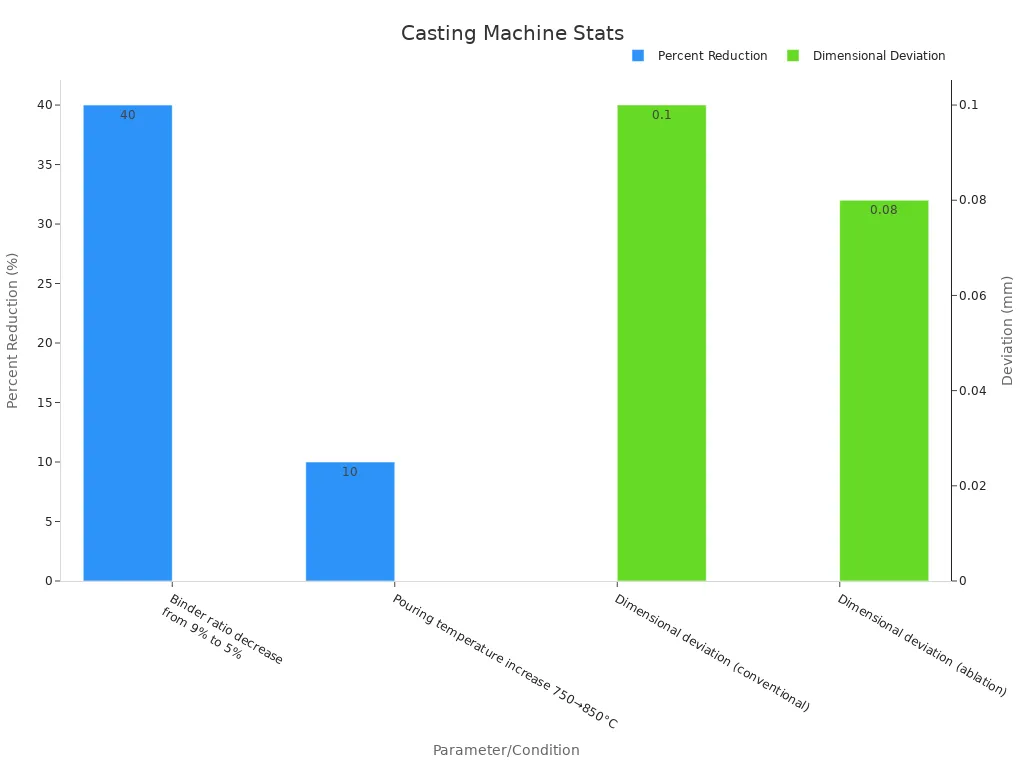

You can see from the chart how production adjustments impact precision:

Key Takeaways

Choose your sand casting machine based on part size, complexity, and production volume to get the best results.

Manual machines offer flexibility for small or custom jobs, while automatic and servo machines boost speed and quality for large runs.

Match your sand and binder type to the metal and casting method to reduce defects and improve surface finish.

Invest in operator training to improve casting quality, reduce errors, and keep your foundry safe.

Plan your facility layout carefully to fit your machine, ensure smooth workflow, and maintain safety.

Regular maintenance and using reliable equipment help avoid downtime and extend machine life.

Consider your budget for initial cost, running expenses, and future upgrades to save money long term.

Use advanced features like real-time monitoring and automation to increase efficiency and maintain consistent quality.

Sand Casting Machine Overview

What Is Sand Casting

You use sand casting to create metal parts by pouring molten metal into a sand mold. This process stands out because it lets you make complex shapes and large parts at a lower cost than many other methods. Sand casting supports many industries, such as automotive, aerospace, and construction. You can see its importance in the table below:

Sand casting remains a critical part of modern manufacturing. You benefit from its flexibility and ability to recycle materials, which supports sustainable practices.

Sand Casting Equipment Basics

You need the right sand casting equipment to ensure high-quality results. Basic casting equipment includes sand mixers, molding machines, core-making machines, and melting furnaces. Each piece of equipment plays a unique role in the casting process. For example, a sand mixer prepares the sand mixture, while a sand casting machine shapes the mold. Quanzhou Juneng Machinery offers advanced sand casting machines that help you achieve precise and repeatable results.

Performance metrics help you measure how well your casting equipment works. You can check sand quality, metal alloy composition, and mold design. You also monitor pouring temperature and rate. Inspection tools like coordinate measuring machines and hardness testers help you confirm the final product meets your standards. When you use reliable sand casting equipment, you reduce defects and improve the quality of your metal casting parts.

Automotive engine casting: Defect rate drops from 5% to 1% with strict quality control.

Aerospace casting: Advanced inspection increases defect detection by 25%.

These results show that careful monitoring and the right casting equipment make a big difference in your production.

Key Roles in the Casting Process

You rely on skilled professionals to manage each step of the casting process. Metallurgists select the right alloys and control melting techniques. Foundry workers design molds and handle pouring. Quality control teams inspect castings using visual checks and advanced tools like X-rays and ultrasonic testing.

Each role affects the final quality of your metal casting. For example, metallurgists help prevent defects like porosity and shrinkage by controlling cooling rates. Quality control teams use non-destructive testing to find hidden flaws. Foundry professionals optimize mold design and pouring methods to ensure smooth finishes and strong parts.

Proper part design reduces defects.

Careful molding and pouring avoid common problems.

High-quality metal and correct melting improve strength.

Heat treatment and finishing enhance surface quality.

Regular inspection ensures every casting meets your standards.

When you combine skilled people with advanced casting equipment from companies like Quanzhou Juneng Machinery, you achieve reliable, high-quality results in every sand casting project.

Types of Sand Casting Machines

Manual Sand Casting Machines

Manual sand casting machines give you full control over the casting process. You shape the sand mold by hand or with basic casting equipment. This method works well for small batches or custom metal casting parts. You can use different flask sizes and patterns, which gives you flexibility. Manual sand casting machines require skilled operators. The quality of each metal casting depends on your technique and attention to detail.

Manual sand casting equipment has lower initial costs. You can use wood or plastic patterns, which saves money on tooling. However, you need more labor and time for each part. Production rates stay low because you handle each step yourself. Mold quality can change from one casting to the next, especially if you have new workers. This method fits best when you need unique or prototype metal casting parts.

Tip: Manual sand casting machines let you experiment with new designs before moving to higher-volume production.

Semi-Automatic Sand Casting Machines

Semi-automatic sand casting machines combine manual skill with mechanized casting equipment. You still control some steps, but machines help with mold handling and compaction. This setup reduces the physical work you do and improves mold quality. You can produce more metal casting parts in less time compared to manual methods.

With semi-automatic sand casting machines, you get a balance between flexibility and efficiency. Mechanized systems handle repetitive tasks, so you focus on quality control and pattern changes. Production rates increase, and you see fewer defects. For example, a foundry using a semi-automatic sand casting machine with an automatic core-setter reached up to 180 uncored molds per hour. This speed helps you meet short to medium production runs without losing quality.

You can adapt existing matchplates with minimal changes, which saves money. Semi-automatic sand casting equipment works well for complex metal casting parts that need careful core setting. You get better consistency and faster cycle times.

Mechanization reduces operator fatigue.

Faster pattern changes support flexible production.

Improved mold quality lowers defect rates.

Automatic Sand Casting Machines

Automatic sand casting machines use advanced casting equipment to automate almost every step of the casting process. You need only one operator to set cores and monitor the machine. These machines deliver high production rates, often making over 200 molds per hour. You get consistent mold quality and reliable results for every metal casting.

Automatic sand casting machines use gravity fill and squeeze methods for deep or complex patterns. They apply optimal squeeze pressure, which increases production speed. You benefit from continuous and stable operation, maximizing output and reducing downtime. Automated systems handle mold preparation, pouring, and post-casting tasks like shakeout and finishing. Real-time monitoring helps you catch defects early.

Manufacturers using automatic sand casting machines report up to 40% cost reductions and higher productivity. You can scale production to meet high-volume demands without major changes. These machines fit best when you need large quantities of metal casting parts with tight quality control.

Note: Quanzhou Juneng Machinery offers advanced sand casting machine solutions that help you achieve high efficiency and consistent quality in your metal casting operations.

You can see that each sand casting machine type fits different production needs. Manual machines give you flexibility for custom work. Semi-automatic machines balance speed and control. Automatic machines deliver the highest output and quality for large-scale metal casting projects. Choosing the right sand casting equipment ensures you get the best results for your casting process.

Servo Molding Machines

Servo molding machines represent the most advanced technology in the sand casting machine industry. You use these machines when you need high precision, speed, and repeatability in your casting process. Quanzhou Juneng Machinery leads the market with its innovative servo molding machines, which use servo motors and programmable controls to deliver unmatched accuracy and efficiency.

You benefit from servo molding machines in several ways:

Servo presses control force and stroke at every point in the cycle. This means you get consistent part quality, even if material or temperature changes.

Programmable velocity profiles let you adjust ram speed during different stages. You can improve accuracy and reduce defects.

Real-time monitoring tracks force, stroke length, position, and velocity. The machine corrects deviations immediately, so you maintain high accuracy.

Servo systems provide precise control over movement and speed. You get accurate positioning and molding every time.

Servo motors deliver high accuracy and repeatability. You can program nuanced speed and force control for each job.

Controlled mold closing reduces stress on components. This extends tool life and keeps your sand casting machine precise.

All-electric servo drives use absolute encoders to detect tiny position shifts. They outperform hydraulic systems, which can change with temperature or age.

Programmable controls let you connect your sand casting machine with other systems. You improve process control and safety.

Servo actuation supports compact mold designs with more cavities. You can double your output and improve cycle times.

Energy savings and reduced maintenance help stabilize operating conditions, supporting precision.

You see these benefits in industries like automotive, where servo presses stamp components with extreme accuracy. Quanzhou Juneng Machinery’s servo molding machines help you achieve these results in your foundry.

Servo Top and Bottom Shooting

You use the Servo Top and Bottom Shooting Sand Molding Machine when you need fast, reliable, and precise sand mold production. This model from Quanzhou Juneng Machinery features a single or double-station four-column structure. The design optimizes the molding process for speed and stability. You can handle both top and bottom sand shooting, which ensures even filling and compaction of the mold. This leads to better surface finish and dimensional accuracy in your castings.

Servo Horizontal Molding

The Servo Horizontal Sand Molding Machine gives you smooth mold handling and pouring operations. Quanzhou Juneng Machinery offers models like JNP3545, JNP4555, and JNP5565. You choose the model based on your production needs and mold size. This sand casting machine uses servo control to move molds horizontally, which improves alignment and reduces the risk of defects. You get consistent, high-quality molds for medium to large production runs.

Servo Sliding Out Molding

You select the Servo Sliding Out Molding Machine series (JNH3545, JNH4555, JNH5565) when you need efficient mold handling and pouring. This sand casting machine uses servo-driven sliding mechanisms to move molds out of the machine smoothly. You reduce manual labor and speed up the casting process. The precise motion control ensures that each mold is handled gently, protecting the mold integrity and improving your casting quality.

Open Conveyor Line

The Servo Molding Machine Open Conveyor Line from Quanzhou Juneng Machinery uses a reliable hydraulic drive system. You benefit from smooth and steady operation, which reduces labor demands and increases your production efficiency. This sand casting machine integrates seamlessly into automated casting lines. You can move molds quickly and safely from one station to the next, supporting high-volume manufacturing.

Tip: When you automate your sand casting process with an open conveyor line, you free up your team for higher-value tasks and boost your overall productivity.

Vertical Sand Shooting and Horizontal Parting

The JN-FBO Vertical Sand Shooting, Molding, and Horizontal Parting Out Box Molding Machine combines several functions in one sand casting machine. You use this machine to shoot sand vertically into the mold, then part the mold horizontally. This design streamlines your casting process and saves space on your foundry floor. You get precise, repeatable molds with less manual intervention. Quanzhou Juneng Machinery’s integrated approach helps you achieve faster cycle times and better casting quality.

Note: Servo molding machines from Quanzhou Juneng Machinery set the standard for precision, speed, and reliability in modern sand casting. You can trust these machines to deliver consistent results, even in demanding industrial environments.

Specialized Sand Casting Equipment

You may need specialized sand casting equipment when your foundry faces unique challenges or advanced production needs. These machines help you create castings that standard sand casting machines cannot handle. Specialized casting equipment often supports industries like automotive, aerospace, and energy, where you must meet strict quality and design standards.

Types of Specialized Casting Equipment:

Rotary Sand Molding Machines:

You use these machines when you want to increase production speed. The rotary table moves molds quickly between stations. This setup helps you make many castings in a short time.Vacuum Sand Casting Machines:

You choose vacuum systems when you need to reduce defects. The vacuum removes air from the mold, which helps molten metal fill every detail. This method gives you smoother surfaces and fewer air pockets.High-Pressure Molding Lines:

You select high-pressure lines for large-scale production. These lines use strong force to compact the sand tightly. You get precise shapes and strong molds, which are important for heavy-duty parts.Automated Pouring Systems:

You rely on automated pouring when you want to control the flow of molten metal. Robots or machines pour the metal at the right speed and temperature. This process keeps your castings consistent and safe.Integrated Core Assembly Machines:

You use these machines to place sand cores inside molds. The machine positions each core exactly where you need it. This step is important for making complex parts with hollow sections.

Tip: Specialized casting equipment can help you solve problems that slow down your production. You can improve quality, reduce waste, and meet customer demands more easily.

Why Choose Specialized Sand Casting Machines?

You may need a specialized sand casting machine if your parts have unusual shapes, tight tolerances, or special material needs. For example, if you make turbine blades or engine blocks, you need equipment that can handle complex molds and high temperatures. Specialized machines also help you automate more steps, which saves time and reduces errors.

Quanzhou Juneng Machinery offers advanced solutions for these needs. Their sand casting machines include servo molding machines, automated lines, and integrated systems. You can find equipment that matches your production goals, whether you need high speed, high precision, or both.

Key Features to Look For:

When you invest in specialized casting equipment, you prepare your foundry for future growth. You can take on more complex projects and deliver better results to your customers.

Note: Quanzhou Juneng Machinery leads the way in specialized sand casting machine technology. You can trust their casting equipment to help you meet the highest industry standards.

Sand Casting Methods and Materials

Green Sand Casting

You often choose green sand casting when you want a cost-effective and flexible method. This process uses a mixture of sand, clay, and water to form molds. You can recycle the sand many times, which helps you save on raw material and waste disposal costs. Green sand casting works well with both manual and automated sand casting machines. Quanzhou Juneng Machinery offers advanced sand casting machines that support both small workshops and large factories.

Green sand casting uses inexpensive materials and supports recyclability.

Automated green sand molding systems require upfront investment but improve efficiency and consistency in large-scale production.

The process has a low thermal load during pouring, so you use less energy than with other casting methods.

You can optimize costs by reclaiming sand, monitoring moisture, and using additives like coal dust for better surface quality.

The durability of green sand cast products makes them ideal for construction and aftermarket parts.

You see green sand casting in many industries, such as automotive, aerospace, and heavy machinery. The process adapts to complex shapes and large components. Automation and digital controls in sand casting machines from Quanzhou Juneng Machinery help you reduce defects and improve quality. The global market for green sand casting continues to grow because of its cost savings and versatility.

No-Bake (Air Set) Casting

No-bake casting, also called air set casting, uses a chemical binder to harden the sand mold at room temperature. You mix sand with a resin binder and catalyst, then pack it around a pattern. The mold sets without heat, so you get strong and precise molds.

No-bake casting gives you better dimensional accuracy and surface finish than green sand casting.

You pay lower tooling costs compared to high-precision methods like die casting.

The mold-making process is simple and adaptable, so you can change designs quickly.

Resin binders reduce labor and make molds more durable, which means fewer defects.

No-bake casting works well for small to medium batch production and lets you prepare molds quickly.

You often use no-bake sand casting machines when you need higher precision or want to make complex parts. Quanzhou Juneng Machinery provides sand casting machines that support no-bake processes, helping you achieve quality results with less manual effort.

Resin Sand Casting

Resin sand casting uses synthetic resins as binders to create strong, rigid molds. You mix sand with resin and a hardener, then shape it in a sand casting machine. The mold cures to form a solid shell, which holds its shape during metal pouring.

You choose resin sand casting when you need high strength and excellent surface finish. This method works well for large castings and parts with fine details. Resin sand molds resist deformation, so you get accurate and repeatable results. Quanzhou Juneng Machinery offers sand casting machines designed for resin sand processes, giving you control over mold quality and production speed.

Tip: When you select the right sand casting method and machine, you improve your casting quality and reduce production costs. Quanzhou Juneng Machinery helps you match your process to your production goals.

Material Selection Factors

When you start a sand casting project, you need to pick the right materials. Your choice affects the quality, cost, and performance of your final product. The type of metal you use, the sand mixture, and the binder all play a big role. You also need to match your material to the sand casting machine you use. Quanzhou Juneng Machinery designs sand casting machines that work with many materials, so you have more options.

Key Factors to Consider:

Type of Metal

You must decide which metal fits your needs. Common choices include iron, steel, aluminum, and bronze. Each metal has its own melting point and strength. For example, aluminum melts at a lower temperature than steel. If you use a sand casting machine from Quanzhou Juneng Machinery, you can handle many metals with the right settings.Casting Size and Shape

The size and shape of your casting affect your material choice. Large castings need sand that can hold its shape. Complex shapes may need finer sand for better detail. Quanzhou Juneng Machinery offers sand casting machines that can handle both small and large molds.Sand and Binder Compatibility

You need to match your sand and binder to your metal. Some metals react with certain binders. For example, green sand works well with iron, but resin sand may be better for aluminum. Your sand casting machine must support the right sand system. Quanzhou Juneng Machinery can help you choose the best setup.Surface Finish and Tolerance

If you want a smooth surface, you need fine sand and a good binder. Some sand casting machines give you better control over compaction and mold quality. Machines from Quanzhou Juneng Machinery use advanced controls to help you get the finish you want.Production Volume

High-volume production needs materials that are easy to handle and recycle. You also want a sand casting machine that can run many cycles without problems. Quanzhou Juneng Machinery builds machines for both small and large production runs.

Tip: Always test your material and sand mixture before starting full production. This helps you avoid defects and wasted time.

When you use a sand casting machine from Quanzhou Juneng Machinery, you get flexibility and support for many materials. You can make better choices and improve your casting results. Always match your material to your machine and your project needs for the best outcome.

Sand Casting Equipment Selection

Part Size and Complexity

When you choose a sand casting machine, you must think about the size and shape of your parts. Large parts need bigger molding boxes and stronger casting equipment. Small parts may need machines with fine control for detail. Complex shapes, such as those with holes or channels, require precise molding and core-making machines.

You should match your sand casting machine to your part’s size and complexity. Quanzhou Juneng Machinery offers machines that handle both large and small parts. Their advanced servo molding machines give you the precision needed for complex designs. When you select the right casting equipment, you reduce defects and improve quality.

Production Volume

Production volume and rate play a big role in your equipment choice. If you make only a few parts each year, you need flexible machines with low setup costs. For high production volume and rate, you want automated sand casting machines that keep costs low per part.

Production volume and rate are key numbers you should track.

Higher production volume and rate lower your cost per part.

Automated casting equipment becomes a smart choice as your production volume and rate grow.

You can start with manual machines and upgrade as your needs increase.

Quanzhou Juneng Machinery provides casting equipment for every scale. Their servo molding machines work well for high production volume and rate, giving you fast cycle times and consistent results. You can plan for growth by choosing machines that let you scale up as your business expands.

Tip: Always match your sand casting machine to your current and future production volume and rate. This helps you save money and meet customer demand.

Surface Finish Requirements

Surface finish matters for many products. If you need a smooth surface, you must pick casting equipment that controls vibration and compaction. Machines with precise controls, like those from Quanzhou Juneng Machinery, help you achieve the finish you want.

Deeper cuts or rough handling can harm surface finish. Use machines that manage force and movement well.

Vibration control is important. Too much vibration causes rough surfaces. Choose a sand casting machine with good balance.

Coolant and heat management affect the final look. Some casting equipment includes systems to keep molds at the right temperature.

Different industries have special needs. Aerospace and medical parts need very smooth surfaces. Automotive parts may need a certain roughness for sealing.

You can measure surface finish using tools that check roughness and waviness. These measurements help you pick the right sand casting machine and process. Quanzhou Juneng Machinery designs casting equipment that meets strict surface finish standards. Their machines help you reduce defects and improve product life.

Note: When you focus on surface finish, you improve how your product looks and works. The right casting equipment makes this easier.

Automation Level

You need to decide how much automation you want in your sand casting machine. Automation level affects your production speed, labor needs, and product quality. Some machines work by hand. Others use robots and computers to do most of the work.

If you choose a manual sand casting machine, you control each step. This gives you flexibility, but it takes more time and skill. Semi-automatic machines help with some tasks, like moving molds or packing sand. You still need to watch the process closely. Fully automatic machines do almost everything for you. These machines use sensors and computers to make sure each mold is the same.

Quanzhou Juneng Machinery offers many types of sand casting machines. You can pick a machine that matches your needs. If you want high speed and less labor, choose a fully automatic or servo molding machine. These machines help you make more parts in less time. They also reduce mistakes and keep your quality high.

Tip: Think about your future needs. If you plan to grow, pick a sand casting machine that lets you add more automation later.

You should also consider your automation and maintenance requirements. More automation can mean less daily work, but you may need skilled workers to set up and fix the machines.

Maintenance and Reliability

You want your sand casting machine to work well every day. Good maintenance and reliability help you avoid downtime and lost money. When you pick a machine, ask about how often it needs service and how easy it is to fix.

Quanzhou Juneng Machinery designs sand casting machines for long life and easy care. Their machines use strong parts and smart controls. You can check the machine’s health with built-in sensors. This helps you spot problems early and plan repairs before something breaks.

Here are some tips to keep your sand casting machine running smoothly:

Follow the maintenance schedule from the maker.

Train your team to spot signs of wear or trouble.

Keep spare parts on hand for quick fixes.

Use the right sand and materials to avoid extra wear.

If you have high automation and maintenance requirements, look for machines with remote monitoring and easy-to-replace parts. This saves you time and keeps your production on track.

Note: Reliable machines from Quanzhou Juneng Machinery help you meet your goals and keep your customers happy.

Budget and Cost Considerations

Your budget is a key factor when you choose a sand casting machine. You need to balance the price of the machine with the benefits it brings. Some machines cost more at first but save you money over time. Others have a lower price but may need more repairs or labor.

Think about these points when planning your budget:

Initial Cost: How much does the sand casting machine cost to buy and install?

Operating Cost: How much will you spend on power, sand, and labor each month?

Maintenance Cost: Will you need to spend a lot on repairs or spare parts?

Upgrade Cost: Can you add new features later without buying a new machine?

Quanzhou Juneng Machinery offers machines for many budgets. Their servo molding machines give you high value because they last long and need less repair. You can talk to their team to find a sand casting machine that fits your budget and your production needs.

Tip: Always plan your budget for both today and tomorrow. A good sand casting machine from Quanzhou Juneng Machinery can help you save money in the long run.

Operator Skill and Training

When you choose a sand casting machine, you must think about the skills of your team. Operator skill and training play a big role in how well your foundry runs. If your workers know how to use the equipment, you get better results and fewer mistakes.

Some sand casting machines need more skill than others. Manual machines require you to shape molds by hand. You must know how to pack sand, set patterns, and check mold quality. If you use a semi-automatic or automatic sand casting machine, you need to understand how to set up the machine, run basic checks, and solve small problems. Servo molding machines from Quanzhou Juneng Machinery use advanced controls. You must learn how to use the touch screen, adjust settings, and read data from sensors.

Tip: Good training helps you avoid accidents and keeps your sand casting machine running smoothly.

You can use this table to see how skill level matches different types of sand casting machines:

You should plan regular training for your team. Quanzhou Juneng Machinery offers support and training for their sand casting machines. You can ask for help with setup, maintenance, and advanced features. When your operators know how to use the equipment, you get better castings and less downtime.

Key steps for building operator skill:

Start with basic safety and machine operation.

Practice mold setup and pattern changes.

Learn to read machine data and spot problems early.

Update training when you add new equipment or features.

Note: Investing in training pays off. Skilled operators help you get the most from your sand casting machine and keep your foundry safe.

Facility and Space Needs

You must also think about your facility and space before you buy a sand casting machine. The size and layout of your foundry affect which machine you can use. Some machines need more room for molds, sand storage, and movement. Others fit into smaller spaces and work well in compact workshops.

Quanzhou Juneng Machinery designs sand casting machines for many types of facilities. You can find machines that fit large factories or small shops. Before you choose, measure your space and plan where each part of the process will go.

Here are some things to check:

Machine Footprint: Measure the length, width, and height of the sand casting machine. Make sure you have enough space for safe operation and maintenance.

Workflow: Plan how molds, sand, and metal will move through your foundry. You want a smooth path from start to finish.

Utilities: Check if you have enough power, air, and ventilation for the machine. Some machines need special hookups.

Storage: You need space for sand, patterns, and finished castings. Keep these areas clean and organized.

Safety Zones: Leave room around the sand casting machine for workers to move safely. Mark walkways and emergency exits.

Tip: Always plan your layout before installing a new sand casting machine. Quanzhou Juneng Machinery can help you design a setup that fits your space and boosts your productivity.

When you match your sand casting machine to your facility, you avoid problems and delays. You also make your foundry safer and more efficient. Good planning helps you get the best results from your investment in Quanzhou Juneng Machinery equipment.

Aluminum Casting Equipment Overview

Aluminum Casting Process

You use the aluminum casting process to create strong, lightweight parts for many industries. This process starts when you melt aluminum and pour it into a mold made from sand or other materials. You can shape complex parts with smooth surfaces and tight tolerances. The process supports both small and large castings, making it flexible for different needs.

Aluminum casting equipment helps you control each step. You can adjust the pouring temperature, sand mixture, and mold vibration. These controls reduce defects like shrinkage and porosity. When you use a sand casting machine from Quanzhou Juneng Machinery, you get reliable results and high-quality parts. The right equipment lets you meet design standards with less finishing work.

Advances in aluminum casting equipment allow you to produce parts quickly and cost-effectively. You can deliver products on time and keep your customers satisfied.

Equipment for Aluminum Sand Casting

You have many types of aluminum casting equipment to choose from. Each type fits a different production goal. For example, you can use manual sand casting machines for prototypes or small batches. Semi-automatic and automatic machines help you make more parts with less labor. Servo molding machines from Quanzhou Juneng Machinery give you precise control and repeatability.

Here are some key features of modern aluminum casting equipment:

High dimensional accuracy and smooth surface finish

Low-pressure die-casting machines that reduce porosity

Advanced control systems for real-time monitoring

Automation that boosts efficiency and reduces downtime

You can also use special devices like mold vibration units. These improve the microstructure of your castings and make them stronger. Simulation tools help you design better molds and optimize the casting process. When you combine these tools with the right sand casting machine, you get fewer defects and better mechanical properties.

Control binder percentage and moisture to reduce defects

Use mold vibration to improve strength and hardness

Apply simulation software to optimize gating and riser placement

Tip: Choose aluminum casting equipment that matches your part size, complexity, and production volume. Quanzhou Juneng Machinery offers solutions for every need.

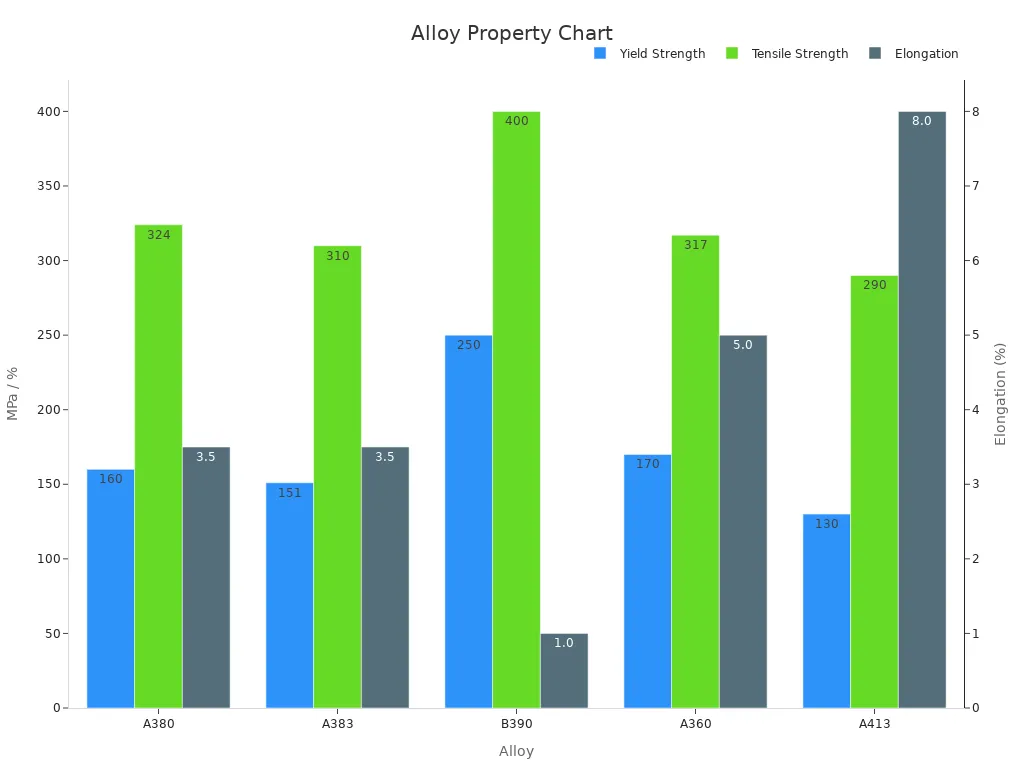

Key Considerations for Aluminum Alloys

When you select aluminum casting equipment, you must think about the alloy you plan to use. Different alloys have unique properties. Some offer high strength, while others provide better ductility or wear resistance. Your equipment must handle the right pressure, temperature, and cooling rates for each alloy.

You should also use real-time monitoring and statistical process control. These tools help you spot trends and keep your quality high. Quanzhou Juneng Machinery designs aluminum casting equipment that supports these features. You can match your sand casting machine to the alloy and process you need.

Note: The right types of aluminum casting equipment help you achieve the best results for each alloy. You can meet industry standards and deliver reliable products.

Sand Casting Machine Comparison

Machine Types vs. Selection Criteria

You face many choices when selecting a sand casting machine. Each type of casting equipment fits different needs. You should compare machine features with your production goals. For example, if you want high speed and accuracy, servo molding machines from Quanzhou Juneng Machinery give you advanced control. Manual machines work best for small batches or custom metal casting. Automatic machines help you produce large numbers of parts with less labor.

A recent comparative study in manufacturing shows that matching machine types to production criteria works best when you use clear performance metrics. Just like in machine learning, where you pick algorithms based on accuracy and precision, you should choose your sand casting machine by looking at mold quality, speed, and cost. Tuning your process, like adjusting sand mix or pouring temperature, helps you get better results. You can apply this approach to both aluminum casting equipment and other metal casting projects.

Tip: Always match your casting equipment to your production needs for the best results.

Matching Machines to Production Needs

You need to think about your product size, shape, and material when picking a sand casting machine. If you work with aluminum casting equipment, you want machines that handle light alloys and give smooth finishes. For heavy metal casting, you need strong casting equipment that can manage high temperatures and large molds.

Quanzhou Juneng Machinery offers a wide range of sand casting machines. You can find the right fit for automotive, pump, or valve parts. Their servo molding machines help you meet strict quality assurance and certification standards. You get reliable results whether you make a few custom pieces or thousands of identical parts.

Use manual or semi-automatic machines for custom or low-volume jobs.

Choose automatic or servo molding machines for high-volume, high-precision production.

Pick casting equipment that matches your space, budget, and operator skill level.

Make sure your sand casting machine supports the materials you use, such as aluminum or iron.

Note: The right casting equipment helps you reduce waste, improve quality, and meet customer demands.

Common Mistakes to Avoid

You can avoid many problems by learning from past mistakes in sand casting operations. Here are some common issues and how they affect your production:

Porosity, shrinkage, and surface defects often come from poor mold filling or bad gating design.

Low pouring temperature or uneven cooling can cause cracks and dimensional errors.

Using the wrong sand or binder leads to weak molds and more scrap.

Skipping quality checks increases the risk of defects in your metal casting.

Not using simulation tools makes it hard to spot problems before production starts.

Poor core design or venting causes inclusions and misruns in your castings.

Failing to standardize processes leads to inconsistent results and higher costs.

You can solve these problems by using advanced casting equipment, like the sand casting machines from Quanzhou Juneng Machinery. Focus on good mold design, controlled pouring, and regular inspections. For aluminum casting equipment, always check temperature and sand quality to avoid defects. Strong quality control keeps your metal casting process efficient and reliable.

Remember: Careful planning and the right sand casting machine help you avoid costly mistakes and deliver top-quality products.

Implementation and Optimization

Preparing for Installation

You need to prepare your facility before installing a new sand casting machine. Start by checking the space and layout. Make sure you have enough room for the machine, sand storage, and safe movement. Measure the area and plan where each part will go. Check your power supply and ventilation. Some machines need special hookups for air or water.

You should also review your workflow. Plan how molds, sand, and metal will move through your foundry. Good planning helps you avoid bottlenecks and keeps your process smooth. Use computer simulations and optimization tools to plan your process. These tools help you design gating, riser systems, and casting parameters before production starts. You can also use IoT-enabled sensors to monitor sand compaction and resin distribution. This step can reduce scrap rates by up to 20%.

Tip: Work with Quanzhou Juneng Machinery to get clear installation guidelines. Their team can help you set up your sand casting machine for the best results.

Training and Support

You must train your team to use the new sand casting machine. Start with basic safety and machine operation. Teach your workers how to set up molds, adjust settings, and check for problems. Quanzhou Juneng Machinery offers training and support for all their machines. Their experts can guide your team through setup, operation, and troubleshooting.

Use semi-automated robotic systems to help your team work faster and safer. These systems can increase output by 30% and reduce the need for manual labor. You should also use data analytics for predictive maintenance. This approach helps you spot issues early and cut downtime by 25%. Regular training keeps your team ready for new challenges and helps you meet quality assurance and certification standards.

Continuous Improvement

You should always look for ways to improve your sand casting process. Start by collecting data from your sand casting machine. Use sensors and analytics to track sand moisture, pouring temperature, and chemical composition. Machine learning models can help you predict defects and guide process changes.

Apply Lean Manufacturing methods to find and remove waste. Use dynamic scheduling algorithms to match production with demand. Try hybrid resin formulations to save energy and improve material efficiency. Energy-efficient equipment can lower your energy costs by up to 35%. Non-destructive testing methods help you catch defects early and keep your products reliable.

Note: Quanzhou Juneng Machinery supports continuous improvement with advanced features and strong after-sales service. Their sand casting machines help you stay ahead in a changing industry.

Selecting the right sand casting machine shapes your production success. You should review your needs, compare machine types, and use the comparison section as a guide. When evaluating suppliers and manufacturers, look for proven support and advanced technology. Quanzhou Juneng Machinery offers sand casting machine options and customized solutions for your foundry. Reach out to experts for advice or a detailed assessment before you decide.

FAQ

What is a sand casting machine?

A sand casting machine helps you shape sand molds for metal parts. You use it to make products in many industries. Quanzhou Juneng Machinery designs machines that improve your casting quality and speed.

How do I choose the right sand casting machine?

You should look at your part size, production volume, and surface finish needs. Quanzhou Juneng Machinery offers machines for small shops and large factories. You can ask their team for advice.

What makes Quanzhou Juneng Machinery’s servo molding machines special?

Servo molding machines from Quanzhou Juneng Machinery use advanced servo motors. You get high precision, fast cycles, and reliable results. These machines help you make complex parts with less waste.

Can I use a sand casting machine for aluminum parts?

Yes, you can use a sand casting machine for aluminum. Quanzhou Juneng Machinery builds machines that handle many metals, including aluminum. You get strong, lightweight parts with good surface finish.

How much space do I need for a sand casting machine?

You need enough room for the machine, sand storage, and safe movement. Quanzhou Juneng Machinery offers compact and large models. You can ask for layout help to fit your foundry.

What support does Quanzhou Juneng Machinery provide after purchase?

You get training, installation help, and fast after-sales service. Quanzhou Juneng Machinery supports you with spare parts and technical advice. You can keep your sand casting machine running smoothly.

How often should I maintain my sand casting machine?

You should follow the maintenance schedule from Quanzhou Juneng Machinery. Regular checks help you avoid breakdowns. Clean your machine, check moving parts, and replace worn items as needed.

Can I upgrade my sand casting machine later?

Yes, many sand casting machines from Quanzhou Juneng Machinery have modular designs. You can add automation or new features as your needs grow. This helps you save money and stay flexible.