In the grand picture of modern industrial production, the foundry industry, as the foundation of the "mother machine of industry," always plays an indispensable role. From automobile engine blocks to the heart of household appliances, countless meta

1. What is a Flaskless Molding Machine? A Paradigm Shift in Casting Technology

In traditional casting, the "flask" is an essential metal or wooden frame used to contain and support the molding sand. However, flasks are cumbersome, management-intensive, costly, and limit the continuity and automation of the molding process. The birth of the Flaskless Molding Machine was precisely to break free from this constraint. As the name suggests, a Flaskless Molding Machine does not use traditional flasks during the molding process. Instead, through the pressure or mechanism of the equipment itself, the sand mold gains sufficient strength to be self-supporting after demolding and can be stacked layer upon layer, enabling continuous pouring.

This is not just a simple upgrade of equipment but a revolution in production philosophy. It represents a key step for casting production toward automation, intelligence, and green manufacturing. As a subsidiary of Fujian Shengda Machinery Co., Ltd., Quanzhou Juneng Machinery has long been deeply involved in the R&D and production of sand injection molding machines and casting molding machines. Its technical understanding and innovation in Flaskless Molding Machines have made its products popular worldwide, exported to dozens of countries including the United States, Brazil, India, Vietnam, and Russia.

2. Working Principle Revealed: The Ingenious Duel of Two Technical Schools

Flaskless molding machines are mainly divided into two technical schools: Vertical Parting Flaskless Molding Machines and Horizontal Parting Flaskless Molding Machines. They share the same goal but have distinct implementation paths, suitable for different production scenarios.

1. Horizontal Parting Flaskless Molding Machine

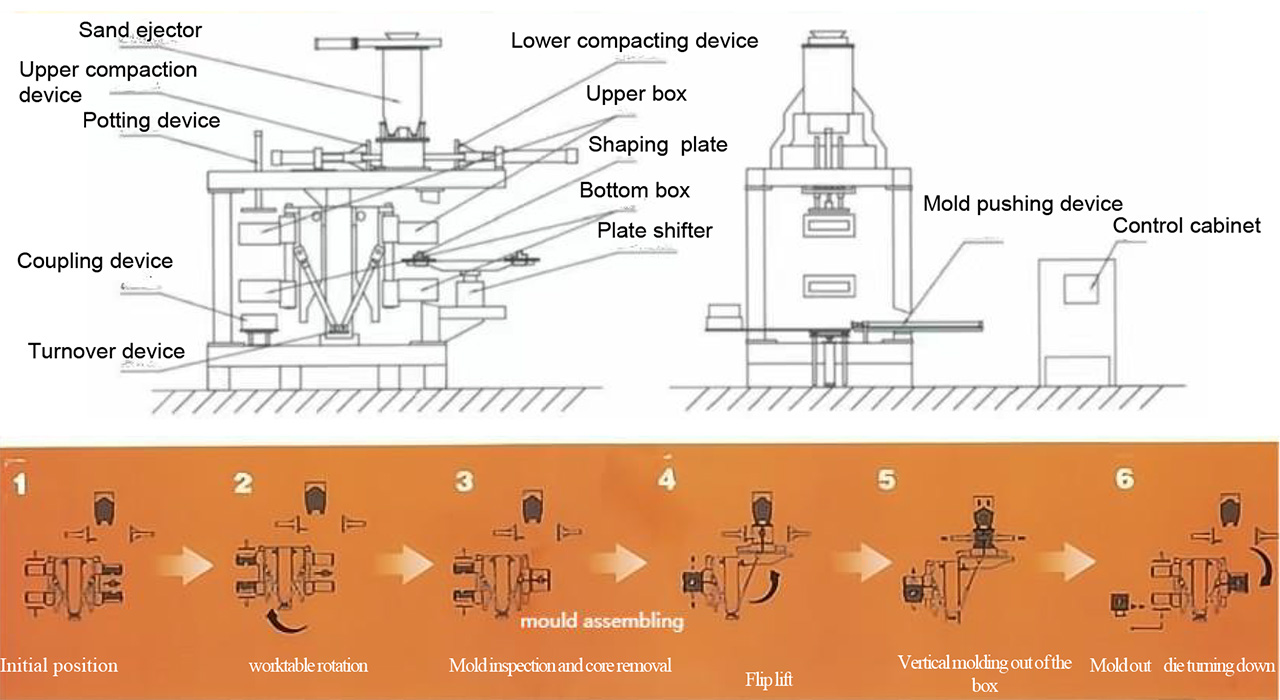

The operation of the Horizontal Flaskless Molding Machine is easier to understand, as it simulates the parting plane direction of traditional flasked molding but omits the flask.

Working Principle:

The Horizontal Parting Flaskless Molding Machine excels in high molding quality and uniform sand strength, especially suitable for castings with relatively complex structures and high dimensional accuracy requirements. The Automatic Horizontal Flaskless Molding Machine fully automates this process, significantly reducing manual intervention.

Sand Filling & Injection: The equipment fills the molding chamber (which already contains the pattern plates) with sand through a high-speed sand injection head.

Compaction: A hydraulic or pneumatic system applies high-intensity compaction to the sand, ensuring the mold reaches the required compactness and hardness.

Demolding & Mold Closing: After compaction, the cope and drag patterns separate from their respective sand halves (demolding). Then, a manipulator flips or translates the completed drag mold to the closing station, where it is precisely joined with the completed cope mold, forming a complete, flaskless mold block.

Pushing & Pouring: The closed mold block is pushed onto a continuous conveyor line, arranged in rows, ready for pouring. The empty molding chamber prepares for the next cycle.

2. Vertical Parting Flaskless Molding Machine

The Vertical Parting Flaskless Molding Machine, or Vertical Flaskless Molding Machine, adopts a more compact and efficient design. Its parting plane is vertical.

Working Principle:

Molding Chamber Preparation: Two pattern plates (corresponding to both sides of the casting) close together vertically, forming a vertical molding cavity.

Sand Injection & Compaction: Molding sand is injected from the top into the vertical cavity, then instantly compacted to very high strength through multi-sided pressure (usually from both sides).

Demolding & Mold Closing: After compaction, the rear pattern plate withdraws, and the front pattern plate advances with the formed sand mold to close with the sand mold from the previous cycle. After closing, the front pattern plate retracts, leaving a continuous string of molds formed by the new and old sand molds combined.

Continuous Pouring: This vertical string of molds moves slowly on the conveyor line, where workers or robots can pour metal from the side. Pouring, cooling, and shakeout are completed continuously at the end of the line.

l components originate from casting. At the core of the casting process—molding (creating sand molds for pouring molten metal)—a technological revolution led by Flaskless Molding Machines is quietly underway, dramatically improving production efficiency and product quality. Today, we take you into Quanzhou Juneng Machinery Co., Ltd., an industry leader specializing in this field, for an in-depth analysis of its flagship products: Vertical Flaskless Molding Machines and Horizontal Flaskless Molding Machines, revealing how they are reshaping the future of the foundry industry.

3. Core Advantages of Juneng Flaskless Molding Machines: An In-Depth Analysis of Industry Leadership

Why are Quanzhou Juneng Machinery's Flaskless Molding Machines so successful globally? The reasons lie in their comprehensive strengths that surpass ordinary equipment manufacturers and the detailed, superior advantages embedded in every aspect of their products.

In-Depth Expansion of Advantages and Selling Points:

1. Ultimate Cost Reduction & Efficiency Boost: Comprehensive Savings from "Explicit" to "Implicit"

Explicit Cost Cutting:

Elimination of Flask Costs: The purchase, maintenance, and replacement of flasks represent a significant ongoing investment in traditional processes. An Automatic Horizontal Flaskless Molding Machine or Vertical Flaskless Molding Machines directly eliminates this expense, offering a clear return on investment.

Revolutionary Labor Cost Reduction: Full automation means only a few technicians are needed for monitoring and maintenance. For example, the Horizontal Parting Flaskless Molding Casting Machine with integrated manipulators can automate core setting, mold closing, and pushing, freeing workers from heavy labor and solving labor shortage issues.

Energy Consumption Optimization: Juneng's Flaskless Molding Machines employ efficient hydraulic systems and intelligent energy-saving modes. Energy consumption significantly reduces during standby or empty cycles, leading to a 15%-30% decrease in comprehensive energy use compared to older equipment.

Implicit Efficiency Gains:

Extremely Fast Cycle Times: Vertical Flaskless Molding Machines Metal Casting technology integrates molding, closing, and pouring into a continuous process, with cycle times measured in seconds, potentially increasing annual capacity several times over.

Maximized Space Utilization: The flaskless design allows molds to be tightly packed or stacked vertically, drastically reducing production line footprint and mold storage space. The Vertical Flaskless Molding Machine itself is compact, offering more flexibility for factory planning.

2. Superior Casting Quality: Dual Assurance of Stability and Precision

High and Uniform Mold Hardness: Juneng's Horizontal Flaskless Molding Machine uses multi-piston high-pressure compaction or air impulse technology, ensuring consistent hardness values (exceeding 90, depending on the process) across all parts of the mold. This directly prevents casting defects like swelling and deformation caused by soft spots in the mold.

Excellent Dimensional Accuracy and Surface Finish: High-precision pattern plate installation and demolding mechanisms ensure a smooth, jitter-free demolding process, replicating sharp, dimensionally accurate mold cavities. This is crucial for producing complex, thin-walled castings. The stability of the Automatic Horizontal Flaskless Molding Machine guarantees consistent molding quality even after millions of cycles.

Repeatable and Traceable Process Parameters: The machine is fully automated by PLC control. Key process parameters like sand injection time, compaction pressure, and hold time are precisely recorded and executed for every cycle, eliminating human operational variability and laying a solid foundation for Total Quality Management and data analysis.

3. Remarkable Flexibility and Adaptability

Quick Pattern Change Technology: Catering to the trend of small batches and high variety, Juneng's Horizontal Parting Flaskless Molding Casting Machine can be equipped with quick pattern change systems, reducing changeover time from hours to minutes, greatly enhancing production line responsiveness.

Wide Process Compatibility: The equipment is suitable not only for traditional green sand but also for various molding materials like resin-bonded sand and sodium silicate sand, offering customers more process options. Whether it's Vertical Flaskless Molding Machines for high-volume gray iron castings or Horizontal Parting Flaskless Molding Machines for higher-grade materials like ductile iron and steel, Juneng can provide customized solutions.

4. Environmental Friendliness and Ergonomic Design

Vastly Improved Working Environment: The equipment is typically enclosed or semi-enclosed, effectively reducing dust and noise diffusion, creating a cleaner, safer workplace compliant with modern EHS (Environment, Health, Safety) standards.

Reduced Waste Sand Discharge: Due to high mold strength and controllable breakdown, the amount of waste sand and dust generated during shakeout is relatively lower, reducing environmental treatment pressure for enterprises.

Intelligent Human-Machine Interaction: Equipped with large touchscreens and intuitive interfaces. Features like fault self-diagnosis display real-time alarm information and suggested solutions, significantly reducing maintenance difficulty and downtime. The addition of remote monitoring allows customers to check equipment status anytime, anywhere.

5. The Added Value of Juneng Manufacturing: Assurance Beyond the Machine Itself

Integrated Solutions: Juneng Machinery is not just an equipment supplier but an "integrated manufacturing service provider for casting molding assembly lines." They can provide turnkey projects covering sand preparation, molding, pouring, cooling, and shakeout, ensuring perfect compatibility between units and avoiding interface issues from different suppliers.

Global After-Sales Service Network: As mentioned in the company profile, its global sales and service network is a key advantage. This means that after purchasing a Juneng Flaskless Molding Machine, customers anywhere in the world can access timely technical support, spare parts, and repair services, ensuring production continuity—a critical factor in measuring the total lifecycle value of the equipment.

4. Main Applications and Industries: Ubiquitous Metal Forming

Flaskless molding machines produce castings found in almost every industrial sector. Key applications include:

Automotive Industry: Engine blocks, cylinder heads, brake discs, transmission housings.

Agricultural & Construction Machinery: Tractor parts, hydraulic components, track shoes.

Plumbing & Hardware: Valves, pipe fittings, flanges.

Power & Electromechanical: Motor housings, pump bodies, gearboxes.

Household Appliances: Air conditioner compressor housings, washing machine counterweights.

Whether it's the diverse, small-to-medium batch precision castings suited for the Horizontal Parting Flaskless Molding Machine, or the high-volume, simpler structure castings ideal for Vertical Flaskless Molding Machines, Juneng Machinery provides corresponding solutions.

5. Typical Parameters of Juneng Flaskless Molding Machines

For a more intuitive understanding, here are typical technical parameters for some of Juneng's Flaskless Molding Machines (Specific model parameters may vary; please refer to the latest official documentation).

Table 1: Horizontal Parting Flaskless Molding Machine Typical Parameters

| Parameter Item | Model JN-HF-800 | Model JN-HF-1000 | Model JN-HF-1200 |

|---|---|---|---|

| Pattern Plate Size (mm) | 800x600 | 1000x800 | 1200x900 |

| Mold Thickness (Cope/Drag mm) | 250/250 | 300/300 | 350/350 |

| Molding Rate (Molds/Hour) | 60-80 | 50-70 | 40-60 |

| Compaction Force (kN) | 2000 | 3000 | 4500 |

| Applicable Sand | Green Sand, Resin Sand | Green Sand, Resin Sand | Green Sand, Resin Sand |

| Control Method | PLC Full Auto | PLC Full Auto | PLC Full Auto |

Table 2: Vertical Parting Flaskless Molding Machine Typical Parameters

| Parameter Item | Model JN-VF-600 | Model JN-VF-800 | Model JN-VF-1000 |

|---|---|---|---|

| Mold Size (mm) | 600x500 | 800x600 | 1000x750 |

| Mold Thickness (mm) | 100-200 | 100-250 | 150-300 |

| Molding Rate (Molds/Hour) | 240-360 | 200-300 | 180-240 |

| Compaction Method | Double-sided Vertical | Double-sided Vertical | Double-sided Vertical |

| Applicable Sand | Green Sand | Green Sand | Green Sand |

| Control Method | PLC Full Auto | PLC Full Auto | PLC Full Auto |

6. Summary and Call to Action

In summary, Flaskless Molding Machines, particularly those produced by technology-driven enterprises like Quanzhou Juneng Machinery, such as the Horizontal Flaskless Molding Machine and Vertical Flaskless Molding Machines, have become core equipment for modern foundries to enhance competitiveness and achieve transformation. By eliminating flasks and enabling continuous automated production, they bring qualitative leaps in efficiency, cost, quality, and environmental performance.

Facing global market opportunities and challenges, Juneng Machinery, with its solid technical积累, excellent product quality, and comprehensive global service network, is helping numerous small and medium-sized foundries worldwide achieve fully automated, highly reliable, and low-cost production goals. Its products like the Automatic Horizontal Flaskless Molding Machine and Horizontal Parting Flaskless Molding Casting Machine are the perfect embodiment of this commitment.

If you are seeking to:

Upgrade the automation level of your existing foundry line?

Build a new, efficient, and energy-saving modern foundry shop?

Find a reliable, durable, and cost-effective Flaskless Molding Machine for your business?

Then, choosing Quanzhou Juneng Machinery Co., Ltd. will be your wise decision.

We sincerely invite you to visit Juneng Machinery's official website or contact our global sales and service offices directly to learn more about our Vertical Flaskless Molding Machines and Horizontal Parting Flaskless Molding Machines. Let Juneng's professional team provide you with a tailored solution to drive your business success together!