In today’s rapidly growing global manufacturing industry, sand casting equipment plays a crucial role as a core technology in the foundry sector. In 2025, a number of outstanding companies have emerged in China’s sand casting equipment manufacturing industry. Among them, Quanzhou Juneng Machinery Co., Ltd. has stood out with its remarkable achievements in the field of casting molding machines, establishing itself as one of the leading enterprises in the industry.

1. Company Overview

Quanzhou Juneng Machinery Co., Ltd. is a subsidiary of Fujian Shengda Machinery Co., Ltd. and is a high-tech enterprise specializing in the R&D of casting molding machines. The company has long been engaged in the research and production of sand casting equipment, with product lines covering sand injection molding machines, casting molding machines, moulding machines for foundry, and complete casting assembly lines.

Guided by the business philosophy of “market-oriented, winning by quality,” the company continuously pursues excellence and innovation, improving its technical strength and industry competitiveness. Today, Juneng Machinery has grown into a diversified, intelligent, and customized integrated manufacturing solution provider for automated molding production lines. Its goal is to deliver fully automatic, reliable, and cost-effective moulding machines for small and medium-sized foundries.

2. Industry Leadership

Quanzhou Juneng Machinery operates a modern factory covering over 10,000 square meters, equipped with advanced production facilities that ensure both product quality and capacity. The company’s sand injection molding machines hold a leading position in the industry and are exported to dozens of countries, including the United States, Brazil, India, Vietnam, and Russia.

To better serve customers worldwide, the company has built a comprehensive after-sales service network, with direct sales offices and authorized agents in multiple regions. Each location is staffed with professional teams handling sales, installation, and technical support, all trained and certified to provide high-quality service. In addition, flexible logistics warehouses guarantee efficient on-site support and reliable product quality assurance.

3. Product Advantages and Technical Parameters

(1) Sand Injection Molding Machine

Juneng’s sand injection molding machines adopt advanced sand shooting technology, ensuring high precision and efficiency in core making. The unique sand shooting head design distributes sand evenly within the mold, enhancing both quality and dimensional accuracy.

Technical Parameters:

Sand shooting pressure: Adjustable between 0.2–0.8 MPa, meeting various compaction requirements.

Sand shooting speed: Up to 50 m/s, significantly improving efficiency.

Mold size range: Supports molds up to 1500 × 1000 × 800 mm.

Production efficiency: 30–60 sand cores per hour, depending on complexity.

(2) Casting Molding Machine

The company’s casting molding machines feature strong molding capacity and excellent stability, suitable for various complex processes. Equipped with a hydraulic drive system, they deliver reliable power and precise operation.

Technical Parameters:

Clamping force: 50–500 tons, customizable per casting requirements.

Molding size: Up to 2000 × 1500 × 1000 mm, ideal for large castings.

Cycle speed: 1–3 cycles per minute, improving productivity.

Control accuracy: Positioning accuracy ±0.1 mm, pressure accuracy ±1%.

(3) Moulding Machine for Foundry

Juneng’s moulding machines utilize advanced automation systems, enabling fully automated molding processes. The efficient sand box conveying system and precise sand compaction technology ensure uniformity and quality.

Technical Parameters:

Sand box size: 400 × 300 × 150 mm (min) to 1200 × 800 × 300 mm (max).

Molding speed: 8–12 molds per minute.

Compaction control: Precisely adjustable for uniform density.

Automation: Features automatic sand feeding, compaction, and demolding.

4. Application Cases

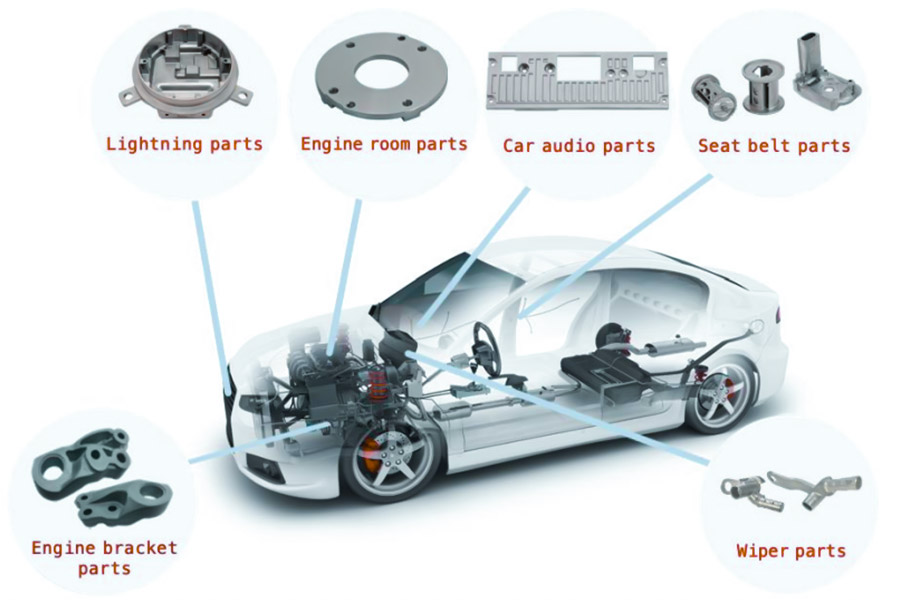

(1) Automotive Parts Casting Industry

A leading auto parts manufacturer faced inefficiencies and inconsistent quality with traditional casting equipment. After adopting Juneng’s sand injection molding machines and casting molding machines, production efficiency increased by 30%, defective sand cores dropped from 5% to below 1%, and casting precision and surface quality improved significantly, reducing costs and enhancing competitiveness.

(2) Machinery Manufacturing Industry

A large machinery enterprise struggled with difficulties in molding and insufficient sand strength for big castings. Juneng provided customized moulding machines and casting assembly lines, optimizing processes and boosting sand strength. As a result, the yield rate improved from 70% to over 90%, and production cycles shortened by 20%.

(3) Aerospace Industry

In aerospace, sand casting is essential for components requiring high strength and precision, such as turbine blades, casings, and brackets. Juneng equipment ensures accuracy and reliability in producing these critical parts.

(4) Construction Industry

In construction, sand casting is widely used for pipe fittings, manhole covers, and other durable components that demand long service life.

(5) Pipeline System Components

Sand casting excels in manufacturing valve bodies, connectors, and joints—core elements in pipeline systems where strength and precision are crucial.

(6) General Metal Manufacturing

Globally, sand casting remains a vital technology in producing diverse metal products, from traditional weapons to cookware. Despite advances in other methods, sand casting continues to dominate due to its cost-effectiveness and suitability for mass production.

5. FAQ

Q1: How do you guarantee product quality?

All equipment strictly follows the ISO9001 quality management system, from raw material sourcing to final inspection. Machines undergo rigorous trial runs and performance testing before delivery. Complete after-sales services, including installation, training, and maintenance, ensure reliability for customers.

Q2: What about pricing?

Pricing varies by model, specifications, and configurations. Juneng provides customized solutions and competitive quotes, balancing quality, performance, and cost-effectiveness.

Q3: What about after-sales service?

Juneng operates global after-sales service centers and authorized agents. Expert technicians provide timely repairs, troubleshooting, and preventive maintenance, ensuring long-term stability.

Q4: What types of sand are used in sand casting?

The most common is silica sand, prized for heat resistance and strength. For higher requirements, zircon sand, chromite sand, and alumina sand may be used.

Q5: What are the types of binders for molding sand?

Common binders include clay, drying oils, sodium silicates, phosphates, and synthetic resins, which enhance mold strength and durability.

Q6: What is the role of coatings in sand casting?

Casting coatings improve surface quality, prevent defects like sticking and inclusions, and consist of refractory powders, binders, carriers, and additives.

Q7: What’s the difference between clay wet sand molding and dry sand molding?

Wet sand molding uses moderate water content and clay as binders, allowing immediate pouring. Dry sand molding requires drying and refractory coating after shaping, suitable for higher precision.

6. Conclusion

As one of the Top 8 Sand Casting Equipment Manufacturers in China (2025), Quanzhou Juneng Machinery Co., Ltd. has earned strong domestic and global recognition through advanced technology, high-quality products, and reliable services. Upholding the philosophy of “market-oriented, winning by quality,” Juneng continues to innovate and support the foundry industry with powerful solutions.

Looking ahead, Juneng remains committed to “pursuing excellence and embracing innovation,” enhancing technical strength and competitiveness, and delivering high-performance, intelligent sand casting equipment and solutions for customers worldwide.

7. Call to Action

If you are seeking high-quality, high-performance sand casting equipment, Quanzhou Juneng Machinery Co., Ltd. is your trusted partner.

🌐 Visit our official website: jnfoundrymachinery.com

📞 Tel: +86-595-82096685

📧 Email: zoe@junengmachine.com

📍 Address: No.62 Chuangxing Road, Intelligent Equipment Base, Anhai Town, Jinjiang City, Fujian Province

We sincerely look forward to cooperating with you and working together to advance the global sand casting industry!