Introduction: From Manual Workshops to Intelligent Foundries

Across the global foundry industry, a fundamental shift is underway. Rising labor costs, stricter quality requirements, and increasing pressure for stable delivery have exposed the limitations of labor-dependent production models. At the same time, Industry 4.0 is no longer a future concept—it is rapidly becoming an operational necessity.

Within this context, the idea of an Unmanned Casting Factory, often described as a “lights-out” workshop, has gained traction. For many foundries—especially small and medium-sized enterprises—the challenge lies not in understanding the vision, but in finding a practical, affordable path to implementation.

This is where the FBO-Vertical molding solution, developed by Quanzhou Juneng Machinery Co., Ltd., plays a decisive role. By combining automation, digital control, and compact vertical molding logic, FBO-Vertical offers a realistic entry point into intelligent manufacturing.

1. Industry 4.0 and the Foundry: Why “Lights-Out” Is No Longer Optional

Traditional foundries rely heavily on manual intervention across molding, handling, and quality control. This structure creates three systemic risks:

High dependency on skilled labor

Inconsistent product quality

Limited scalability and data transparency

An Industry 4.0 Casting Machine addresses these challenges by embedding intelligence directly into production equipment. Instead of reacting to problems, the system anticipates and prevents them through data-driven control.

The transition toward Smart Foundry Equipment is therefore not about replacing people, but about redefining the role of humans—from operators to supervisors of intelligent systems.

2. FBO-Vertical: The Automation Backbone of an Unmanned Casting Factory

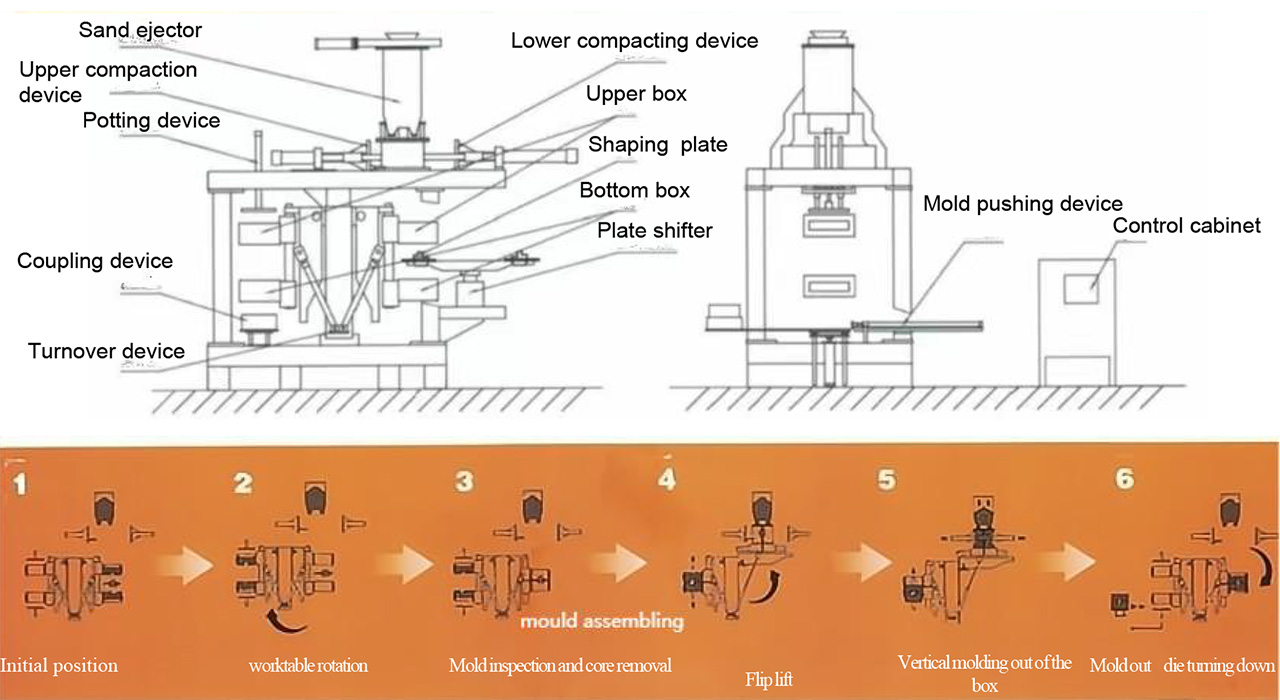

At the core of the FBO-Vertical solution is a fully integrated Automatic Molding System designed for continuous, stable, and unattended operation.

Key functional characteristics include:

Automated sand injection and compaction

Program-controlled mold forming cycles

Continuous vertical mold alignment and transfer

These functions enable the system to operate for extended periods with minimal human presence, making the concept of an Unmanned Casting Factory operationally feasible.

Unlike traditional upgrades that require complex peripheral automation, FBO-Vertical integrates automation at the molding core, ensuring higher reliability and lower system complexity.

3. Digitalization as the Enabler of Intelligent Control

Automation alone does not create intelligence. True transformation occurs when automation is combined with Digital Foundry Solutions.

The FBO-Vertical system supports:

Real-time monitoring of molding parameters

Digital recipe management for different casting types

Automatic deviation alerts and fault diagnosis

By digitizing the molding process, foundries gain full visibility into production stability and efficiency. This data foundation is essential for implementing Smart Foundry Equipment strategies aligned with Industry 4.0 standards.

4. Performance Comparison: Traditional Workshop vs. FBO-Vertical Smart Line

| Performance Indicator | Traditional Molding Line | FBO-Vertical Intelligent Line |

| Labor Requirement | High | Reduced by 40–60% |

| Process Stability | Operator-dependent | Digitally controlled |

| Data Transparency | Low | Full real-time visibility |

| Downtime Risk | Frequent | Predictive control |

| Upgrade Flexibility | Limited | Modular and scalable |

This comparison highlights why the Automatic Molding System is the structural foundation of any Industry 4.0 Casting Machine deployment.

5. A Realistic Path for SMEs: Intelligence Without Overinvestment

For small and medium-sized foundries, intelligent transformation must be cost-controlled and scalable. FBO-Vertical addresses this requirement through:

Modular system architecture

Gradual automation expansion

Compatibility with existing sand systems

Rather than pursuing a one-time, high-risk overhaul, foundries can evolve step by step toward an Unmanned Casting Factory model. This approach lowers financial risk while delivering measurable efficiency gains.

6. Environmental and Operational Synergy

In addition to productivity gains, FBO-Vertical contributes to sustainability objectives. Compact vertical layouts reduce energy consumption, while enclosed system design improves dust control and noise management.

This synergy between operational efficiency and environmental responsibility reinforces the value of Digital Foundry Solutions in modern manufacturing strategies.

7. Frequently Asked Questions (FAQ)

Q1: Can FBO-Vertical really operate without operators on-site?

Yes. With automated control and remote monitoring, the system supports extended unattended operation.

Q2: Is it suitable for SMEs with limited automation experience?

Absolutely. The system is designed for gradual adoption and intuitive operation.

Q3: How does it align with Industry 4.0 standards?

FBO-Vertical functions as a true Industry 4.0 Casting Machine, integrating automation, data collection, and digital control.

Q4: What types of castings are supported?

The system is suitable for a wide range of small to medium iron and ductile iron castings.

Q5: Is ROI predictable?

Most customers achieve cost recovery through labor savings and yield improvement within 2–3 years.

8. Industry Outlook: From Automation to Autonomous Manufacturing

Globally, foundries are moving beyond automation toward autonomous production. As data, equipment, and process intelligence converge, the Unmanned Casting Factory will become the benchmark rather than the exception.

In this evolution, Smart Foundry Equipment such as FBO-Vertical plays a critical enabling role—especially for enterprises seeking competitiveness without excessive capital burden.

Conclusion: Intelligent Manufacturing Starts at the Molding Core

The transformation toward intelligent manufacturing does not begin with complex software platforms. It starts with stable, automated, and digitized core equipment.

By integrating an advanced Automatic Molding System, practical Digital Foundry Solutions, and Industry 4.0-ready architecture, FBO-Vertical provides foundries with a clear and achievable path toward intelligent, unmanned production.

Quanzhou Juneng Machinery Co., Ltd. continues to focus on delivering reliable, cost-effective solutions that bridge traditional casting expertise with the future of smart manufacturing.

Call to Action

If your foundry is facing:

Labor shortages and rising costs

Pressure to improve consistency and delivery

The need to adopt Industry 4.0 without excessive risk

We invite you to explore how FBO-Vertical Smart Foundry Equipment can support your transformation journey.

Contact Juneng Machinery to request:

A smart foundry feasibility assessment

A customized automation upgrade roadmap

A visit to an operational FBO-Vertical intelligent line

From automation to autonomy—build your future foundry today.