1. The “Fog of Quality” in Traditional Foundries

In a typical sand casting workshop, dust and humidity fill the air. Skilled workers rely on touch and intuition—grabbing a handful of molding sand, pressing it gently, and guessing whether the moisture content feels right. But one wrong judgment can ruin an entire batch of castings: porosity, sand inclusion, and burn-on defects appear everywhere.

Across the industry, “sand problems” are the root of most casting defects.

When sand hardness and moisture fluctuate, scrap rates rise sharply. Studies show that for a mid-sized foundry producing 3,000 tons annually, inconsistent molding sand can cause RMB 800,000–1.5 million in scrap losses every year.

In today’s era of tight margins and intense competition, these invisible losses are forcing foundries to embrace intelligent and data-driven manufacturing.

2. The Hidden Pain Points in Sand Casting

To truly achieve high yield and consistent quality, foundries must address three critical pain points head-on.

| Key Process | Common Problem | Result & Impact |

|---|---|---|

| Sand Treatment | Fluctuations in moisture, clay content, and compactability | Unstable sand strength and more casting defects |

| Molding Process | Uneven density, poor stripping accuracy | Mismatch, collapse, or localized porosity |

| Human Factor | Heavy reliance on operator experience | Uncontrolled variation and inconsistent standards |

In green sand casting, every 0.5% deviation in moisture can cause up to 3% variation in hardness. That means every unmonitored process becomes a potential source of defect.

3. From Experience to Intelligence: The Smart Revolution

Facing these challenges,Quanzhou Juneng Machinery Co., Ltd., a subsidiary of Fujian Shengda Machinery Co., Ltd., has redefined what green sand casting equipment can be in the Industry 4.0 era.

Their vision: transform each grain of sand into a measurable data point and make every molding cycle precisely repeatable.

4. The Smart Foundry Solution Framework

(1) The “Smart Sand Eye”: Real-Time Sand Condition Monitoring

Traditional sand control relies on delayed lab tests. Juneng’s Smart Sand Eye changes that. Equipped with online sensors, it continuously measures moisture, density, temperature, and clay activity. When a parameter drifts from its ideal range, the system automatically adjusts the sand mixer’s water and binder ratios, creating a self-correcting closed-loop.

Each batch of sand is automatically stabilized—ensuring consistent hardness across all molds.

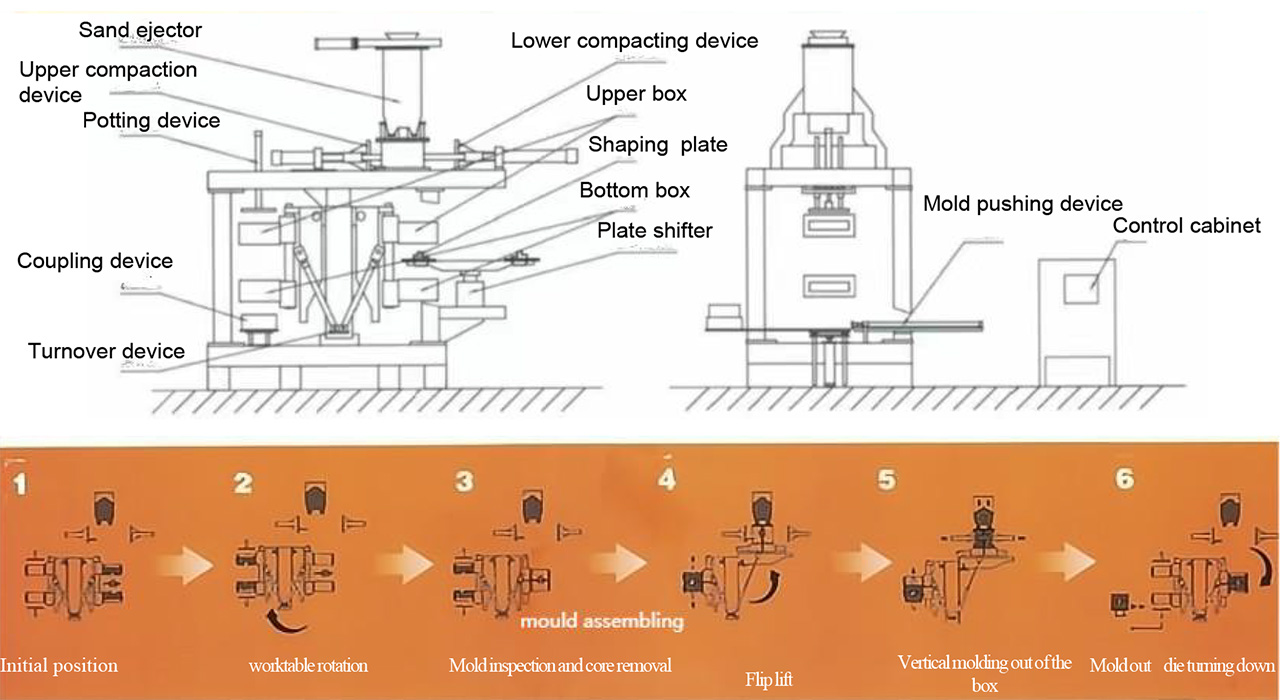

(2) Data-Driven Molding: Servo Precision and Digital Reproducibility

In conventional molding, shooting pressure and compaction are set by experience.

Now, servo-driven automatic molding machines collect and reproduce every shot pressure, vibration, and compaction parameter with millisecond precision.

Through advanced control algorithms, each mold’s hardness variation stays within ±1%.

This evolution transforms sand casting equipment from “mechanical molding” into truly intelligent molding.

(3) End-to-End Traceability: MES Quality Loop

Juneng integrates every production stage—sand mixing, molding, pouring—into a single MES data platform.

Each mold’s raw material batch, moisture content, compaction force, and final casting ID are recorded in real time. When defects occur, engineers can instantly trace the exact cause.

This kind of data-visible quality control is helping more foundries achieve “zero-defect” manufacturing.

5. Case Study: From 5% Scrap to 1.3% and 30% Higher Output

A Zhejiang-based automotive foundry implemented Juneng’s smart sand treatment system and automated molding line. Within months, results were transformative.

| Metric | Before Upgrade | After Upgrade |

|---|---|---|

| Casting Scrap Rate | 5.0% | 1.3% |

| Daily Output | 320 molds/day | 420 molds/day |

| Labor per Shift | 8 workers | 5 workers |

| Energy Cost | 100% baseline | -15% |

Through intelligent moisture and clay control, casting defects such as porosity and burn-on decreased dramatically.

Data-driven molding and MES traceability improved the process capability index (CpK) to 1.67, meeting top-tier automotive supply standards.

This project stands as a benchmark of how industrial sand casting equipment enables small and medium foundries to enter the era of digital transformation.

6. Technical Comparison: Smart vs. Traditional Green Sand Systems

| Parameter | Traditional Equipment | Intelligent Green Sand Casting Equipment |

|---|---|---|

| Sand Uniformity | Manual adjustment, high variation | Real-time closed-loop control (±1%) |

| Data Logging | None | Continuous real-time recording |

| Fault Detection | Reactive | Predictive, early warning |

| Model Change Time | ~20 minutes | ≤5 minutes |

| Scrap Rate | 3%–6% | 1.0%–1.5% |

| Energy Consumption | Baseline | -10% to -15% |

| Labor Intensity | 8–10 workers | 3–5 workers |

The essence of intelligence is not complexity—it’s adaptability.

Modern industrial sand casting equipment is evolving into the digital “heart” of the foundry.

7. Industry Outlook: The Future of Intelligent Sand Casting

According to the China Foundry Association’s 2025 report, by 2030, over 70% of medium and large foundries will have completed digital upgrades of their main production lines.

The green sand casting equipment market is projected to grow at a CAGR of 8.2%.

Hunter sand casting equipment and other global brands still dominate premium markets, but Chinese manufacturers are closing the gap in smart customization and service responsiveness.

Industrial IoT integration will become the next competitive battleground.

Modular, phased upgrades allow small foundries to achieve “flexible automation” without full-line replacement.

The next decade’s competition will no longer be between machines—but between smart ecosystems.

8. FAQ: Common Questions from Foundry Managers

Q1: Is intelligent sand casting suitable for small foundries?

Yes. Juneng’s system is modular—starting from a single molding unit and scaling up to a complete automated line. ROI is typically within 18–24 months.

Q2: Can it integrate with existing sand systems?

Yes. Custom interfaces ensure seamless compatibility with current mixers, vibrators, and conveyors.

Q3: Is maintenance difficult?

Not at all. The system features remote diagnostics, auto alarms, and user-friendly dashboards—no coding required.

Q4: How secure is the production data?

Data is locally stored with multi-layer encryption and offline backup to protect proprietary information.

Q5: Can it auto-adjust for different casting types?

Yes. The recipe management module recognizes mold types and automatically adjusts shooting and compaction parameters for true flexible production.

9. Conclusion: From “Casting Quality” to “System Quality”

Foundry competitiveness is shifting—from comparing machines to comparing intelligence.

When every sand casting equipment can self-learn, self-correct, and self-optimize, the age of “experience-based production” will be replaced by “data-driven manufacturing.”

With more than a decade of R&D experience, Quanzhou Juneng Machinery Co., Ltd. provides scalable, intelligent manufacturing solutions for small and medium foundries worldwide.

Through its green sand casting equipment, Hunter sand casting equipment, and industrial sand casting equipment series, Juneng is helping global partners achieve the dual goals of zero defects and high output.

⚙️ Free Tool & Call to Action

Curious how ready your foundry is for smart manufacturing?

Juneng Machinery — where every grain of sand understands manufacturing.