Over the past decade, the global foundry industry has undergone a remarkable transformation. Automation, intelligence, and energy efficiency have become the three defining factors for modern molding equipment.

Amid this efficiency revolution, Chinese manufacturers are emerging as the global innovators in flaskless molding technology.

From traditional vertical parting equipment to today’s Horizontal Parting Flaskless Molding Machine, the evolution in molding design represents not only mechanical improvement but also a revolution in casting philosophy.

Quanzhou Juneng Machinery Co., Ltd. stands at the forefront of this global transformation.

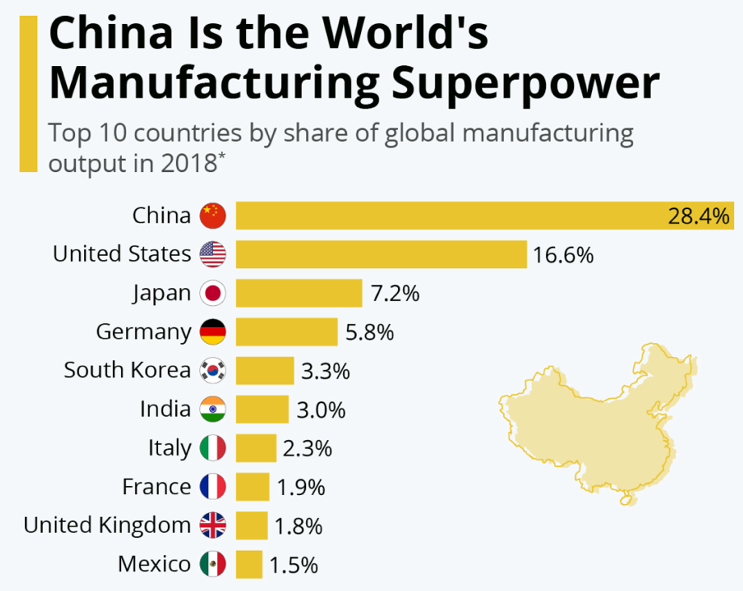

1. From Cost Advantage to Technology Leadership: The Rise of Chinese Manufacturing

For years, “Made in China” was associated with “low-cost production.” That perception is now changing.

As labor costs rise and international buyers demand more automation and precision, Chinese foundry equipment suppliers are redefining global standards with technology-driven innovation rather than price competition.

Among these advancements, the Automatic Horizontal Flaskless Molding Machine has become a symbol of high-performance, high-efficiency production.

This new generation of Horizontal Parting Flaskless Molding Casting Machines is replacing conventional molding lines across Europe, Southeast Asia, and the Middle East—setting new benchmarks for productivity and casting accuracy.

2. Core Technology: The Horizontal Sand Injection Breakthrough

Why Choose Horizontal Parting?

Traditional vertical parting systems face inherent limitations in mold density and complexity:

Uneven sand compaction in thicker molds;

Higher mechanical stress on patterns;

Difficulty in producing thin-walled or complex castings.

By contrast, the Horizontal Parting Flaskless Molding Machine injects sand laterally, ensuring more uniform density distribution and greater mold precision.

Its key advantages include:

| Technical Aspect | Vertical Parting System | Horizontal Parting System (Juneng Solution) |

|---|---|---|

| Sand Density Uniformity | Moderate | Excellent (density variation < ±3%) |

| Pattern Impact Force | High | Reduced by over 30% |

| Complexity Support | Moderate | Supports complex, thin-wall, hollow castings |

| Pattern Change Time | 10–15 minutes | 3–5 minutes |

| Maintenance Interval | Short | Doubled lifespan |

Intelligent Integration: A Symbol of Advanced Engineering

The Horizontal Flaskless Molding Machine by Quanzhou Juneng Machinery Co., Ltd. features modular construction and an intelligent control system with:

Automatic sand volume and density control;

Quick-change pattern system;

One-touch parameter recall;

Remote diagnostic and maintenance capabilities.

Before leaving the factory, every molding machine undergoes 200+ hours of continuous full-load testing, ensuring stability, precision, and durability that meet or exceed international standards.

This rigorous process guarantees that Juneng’s Automatic Horizontal Flaskless Molding Machines perform reliably even under 24/7 industrial workloads.

3. Competing Globally: China’s New Manufacturing Advantage

For decades, German and Japanese manufacturers dominated the foundry equipment market. However, with the rise of global supply chains and digital automation, Chinese manufacturers like Juneng are now matching—and sometimes surpassing—them through three strategic advantages:

| Comparison Factor | German/Japanese Equipment | Chinese Juneng Equipment |

|---|---|---|

| Procurement Cost | High | Moderate (20–35% lower) |

| Core Component In-house Rate | <50% | >85% |

| Customization Lead Time | 3–6 months | 2–4 weeks |

| After-sales Service | High cost | Localized support |

| ROI Cycle | 3–5 years | 1.5–2 years |

Thus, the Horizontal Parting Flaskless Molding Machine from China is not merely a cost-effective choice — it’s a smart, high-return investment for forward-thinking foundries.

4. Market Data: Flaskless Molding Machines on the Rise

According to data from the Foundry Technology Research Institute, the global Flaskless Molding Machine market is expected to grow at a CAGR of 7.8% from 2023 to 2028.

Within this segment, horizontal parting systems are forecasted to expand even faster—at 10.2% annually—driven by:

Higher energy and material efficiency demands;

Rising need for high-precision and complex castings;

Labor shortages accelerating automation adoption.

| Region | Growth Rate | Key Applications |

|---|---|---|

| Europe | 6.5% | Precision castings, auto parts |

| Southeast Asia | 8.3% | Engineering machinery, agriculture |

| China | 9.7% | Industrial tools, die-casting molds |

| North America | 5.9% | Aerospace, energy sectors |

China has become one of the most dynamic growth engines in this global transformation.

5. Case Studies: Engineering Excellence, Global Reach

At its modern factory in Fujian, Quanzhou Juneng Machinery Co., Ltd. manufactures and exports Automatic Horizontal Flaskless Molding Machines for over 30 major foundries worldwide, including those in:

Germany, Poland, Thailand, and Turkey;

Automotive, hydraulic, valve, and grey iron casting industries.

Client results demonstrate the machine’s measurable benefits:

After adopting Juneng’s Horizontal Parting Flaskless Molding Casting Machines,

productivity increased by 32%, labor cost dropped 40%, sand usage decreased 18%,

and rework rates fell by 25%.

Such data-backed performance proves that Chinese equipment is now synonymous with both efficiency and reliability.

6. FAQ: Common Questions About Flaskless Molding Machines

Q1: What mold sizes can the Horizontal Parting Flaskless Molding Machine support?

A: Customizable—standard models support 550×450mm up to 900×700mm.

Q2: Can it integrate with existing pouring lines?

A: Yes. The system fully supports PLC integration and real-time data collection with your existing casting line.

Q3: What is the energy consumption profile of the Automatic Horizontal Flaskless Molding Machine?

A: Energy use is reduced by approximately 20%, and sand recycling efficiency exceeds 95%.

Q4: Are the machines compliant with export standards?

A: All models meet CE and ISO9001 certifications and come with an English-language interface and remote service capability.

Q5: What’s the maintenance cycle?

A: Routine inspection every 6 months is sufficient; maintenance costs are 20% lower than the industry average.

7. Conclusion: Efficiency Revolution, Powered by China

From molding precision to production efficiency, and from cost optimization to intelligent automation,

the Horizontal Parting Flaskless Molding Machine by Quanzhou Juneng Machinery Co., Ltd. represents the next stage in China’s evolution from “Manufacturing” to “Smart Manufacturing.”

In today’s foundry industry, China is no longer just a participant—it’s redefining the rules.

For foundries seeking long-term production stability, higher precision, and maximum ROI, understanding the engineering capability of China’s leading manufacturers is no longer optional—it’s essential.

Contact Juneng Machinery today to learn more about tailored molding solutions and full-line project planning.

Let Chinese engineering power your next leap in casting efficiency.

About Quanzhou Juneng Machinery Co., Ltd.

Quanzhou Juneng Machinery Co., Ltd., a subsidiary of Fujian Shengda Machinery Co., Ltd., is a high-tech enterprise specializing in Sand Injection Molding Machines, Casting Molding Machines, Flaskless Molding Machines, and automated foundry lines.

With decades of R&D experience, Juneng is committed to the philosophy of “Quality Development, Reputation for Survival.”

By integrating innovation, precision manufacturing, and global service, Juneng provides intelligent, stable, and efficient molding solutions for foundries around the world.