A green sand molding machine shapes sand into molds by compacting it around a pattern. You use this machine to create strong, accurate molds for metal casting. Mastering the working principle helps you improve casting quality and reduce waste. Recent advances, like servo technology and wireless sensors, let you control the process more precisely.

Advanced green sand molding tools detect process shifts in real time, lowering scrap rates and boosting quality.

Digital clay measurement methods keep your green sand system stable.

Wireless sensors in molds track variations and help you optimize each casting.

Key Takeaways

Green sand molding machines shape moist sand into strong molds for metal casting, improving speed and accuracy.

The machines use compaction methods like jolting and squeezing to pack sand tightly around patterns, ensuring mold strength.

Automation and servo technology boost production speed, reduce defects, and maintain consistent mold quality.

Proper sand preparation, including mixing and moisture control, is essential for making durable and defect-free molds.

Careful pattern placement, sand filling, compaction, and mold release steps help produce precise and high-quality castings.

Green sand molds can be reused many times, making the process cost-effective and environmentally friendly.

Modern machines save energy, reduce emissions, and support sustainable foundry practices.

Following best practices in machine setup, sand quality control, and safety leads to better casting results and safer work environments.

Green Sand Molding Machine

Definition

You use a green sand molding machine to shape sand into molds for metal casting. This machine uses a mixture of sand, clay, water, and additives. The term "green" means the sand is moist, not that it is colored. The machine compacts this mixture around a pattern to create a cavity. You then pour molten metal into this cavity to form a casting. Green sand molding is popular because it is fast, cost-effective, and easy to reuse.

Key Components

A green sand molding machine has several important parts. Each part helps you create strong and accurate molds.

Storage silos hold and dispense the sand mixture.

Mullers mix sand, clay, water, and additives to get the right texture.

Aerators condition the sand by adding air, making it easier to compact.

Mold making units shape the sand around the pattern.

Pouring stations let you add molten metal to the mold.

Shakeout units separate the finished casting from the sand mold.

Dust collectors filter the air and keep your workspace clean.

Sand reclamation equipment, like metal separators, sand coolers, and screening units, help you reuse sand and reduce waste.

You also use patterns and flasks or flaskless systems to shape the mold. Sand conditioning and compacting equipment make sure the mold is dense and strong. Some machines use vertical or horizontal molding systems. Vertical molding can make high-density molds quickly and without flasks. Matchplate molding systems help you save labor and maintenance costs.

Purpose

You use a green sand molding machine to automate and improve the mold-making process.

The machine forms molds quickly and with high precision.

Automation reduces manual labor and increases productivity.

You get accurate molds, which means better casting quality.

The process supports sustainability because you can reuse sand and minimize waste.

You can customize the machine for different casting sizes and shapes.

The machine helps you produce many molds in a short time, making it ideal for high-volume production.

Smart features, like programmable logic controllers and sensors, help you control the process and keep quality high.

The machine supports sustainable foundry practices by recycling sand and using energy-efficient designs.

Tip: Using a green sand molding machine helps you save time, reduce costs, and improve the quality of your castings. You also help the environment by reusing sand and reducing waste.

Working Principle

Compaction Methods

You use several compaction methods in a jolt squeeze molding machine to create strong and accurate molds. Each method helps you achieve the right density and surface finish for your casting.

Jolting

Jolting is the first step in the compaction process. You fill the flask with green sand and then lift and drop it repeatedly. This action settles the sand downward, packing it tightly around the pattern. The jolt squeeze molding machine uses vertical impact to make sure the sand fills every space. You get better mold strength and fewer defects with this method.

Squeezing

After jolting, you apply squeezing. The jolt squeeze molding machine presses down on the sand from above. This pressure compresses the sand even more, making the mold denser and more uniform. Squeezing improves the surface finish and reduces the risk of casting flaws. The machine uses a micro vibration compaction mechanism and a large shock force to reach high compaction strength. You do not need a pre-shock step, which saves time and energy.

Air Impact

Some jolt squeeze molding machines use air impact to help with compaction. Pneumatic components push air into the sand, making it easier to settle and compress. This method gives you more control over the compaction process. You can adjust the air pressure to match the sand's moisture and grain size. The machine often includes a buffer spring to reduce impact and a synchronous pattern stripping mechanism for easy mold removal.

Note: The green sand composition, including silica sand, clay, water, and additives, is critical for proper compaction. You must check the moisture content to get the best results from your jolt squeeze molding machine.

Mold Formation

You form a mold by shaping green sand around a pattern inside the jolt squeeze molding machine. The properties of the sand, such as flowability, grain shape, and packing density, play a big role in this process. You mix sand grains with binders and catalysts to control how well the sand flows and how strong the mold becomes. You measure flowability by looking at the sand repose angle. A good repose angle, usually between 25° and 30°, means the sand flows well and fills the mold evenly. Rounded grains help the sand flow but may lower mold strength. Angular grains make the mold stronger but can leave a rougher surface. You use fine aggregate analysis to check grain shape and void percentages. These measurements help you adjust the sand mix for the best mold quality.

Automation Advances

Modern jolt squeeze molding machines use advanced automation to improve accuracy and repeatability. You find features like PLC and CNC control systems that let you run the machine automatically. This reduces human error and keeps each mold consistent. Servo-driven hydraulic compaction systems give you fast and steady compaction. You can make molds with tolerances as tight as ±0.3mm. Automation also speeds up the process. You can produce 80–120 molds per hour, compared to only 30–50 molds per hour with older machines. Robotic mold handling and IoT-enabled sensors let you monitor and adjust the process in real time. This keeps the sand distribution and compaction pressure uniform, which lowers the defect rate by up to 20%. You get higher productivity and better casting quality.

Juneng’s Servo Molding Machines show how automation and servo control technology can transform your molding process. These machines use servo-driven systems for precise motion control. You get high repeatability and accuracy in every mold. The advanced design of Juneng’s jolt squeeze molding machine models, such as the Servo Top and Bottom Shooting Sand Molding Machine, ensures you meet strict industrial standards. You can rely on these machines for consistent results, whether you work with small or large castings.

Tip: By using a modern jolt squeeze molding machine with servo control, you can boost your foundry’s efficiency and product quality. Automation helps you make more molds in less time and with fewer defects.

Green Sand Molding Process

Sand Preparation

You start the sand casting process by preparing the sand mixture. This step is critical for the quality of your mold and the final casting. You use a muller to mix sand, clay, water, and sometimes organic binders. The muller keeps the bentonite clay properties intact, which helps the sand stick together during molding. If you use organic binders, you might use a screw mixer to spread the resin evenly.

You must add binders carefully. These binders coat each sand grain, making the mixture strong enough for the molding process. You take samples from the mixer and test them for compression strength, Loss on Ignition (LOI), and permeability. These tests help you check if the sand mixture meets your specifications. If the results are off, you adjust the water, carbon, or clay content.

Controlled mixing and regular testing ensure you get a consistent sand mixture. This consistency is vital for the sand casting process because it affects the strength and surface finish of your mold. The table below shows the main steps and checks in sand preparation:

You need to monitor moisture, green strength, and clay levels. Uniform water distribution prevents dry spots or excess water, both of which can weaken your mold. When you control these factors, you set the foundation for a successful sand casting process.

Pattern Placement

After preparing the sand, you move to pattern placement. The pattern shapes the cavity in your mold, which will form the final casting. You must place the pattern with precision. If you use automated systems, you can achieve tight tolerances and repeatable results. This step is important for the metal casting process because it affects the accuracy and surface finish of your casting.

You inspect the pattern using tools like Coordinate Measuring Machines (CMM). These inspections make sure the pattern matches the required dimensions. You also check the surface condition to prevent defects from transferring to the casting. When you use 3D scan data or reverse engineering, you can place patterns even more precisely. Virtual assembly analysis helps you align mold halves and cores, reducing errors and improving the final product.

You must consider shrinkage allowances, parting planes, and alignment features. These design details help you remove the pattern without damaging the mold. Proper pattern placement leads to better sand casting processes and higher-quality castings.

Tip: Always check the pattern for damage or wear before starting the molding process. A damaged pattern can cause defects in every casting you make.

Sand Filling

Once you place the pattern, you begin sand filling. You fill the flask with the prepared sand mixture, making sure it surrounds the pattern completely. Uniform sand packing is essential. If you pack the sand unevenly, you risk weak spots in the mold, which can cause casting defects.

You control the sand grain fineness, binder ratio, and pouring temperature during this step. Studies show that optimizing these parameters can improve dimensional accuracy by 31.6%, increase hardness by 58.9%, and boost ultimate tensile strength by 41.82% in castings. Proper mulling ensures the clay and water mix evenly, which strengthens the mold. Mechanical shear during mulling activates the clay, making the sand stick together better.

You must monitor moisture percentage, green strength, and methylene blue clay levels. Uniform water distribution is key. If you have dry spots or free water pockets, the mold quality drops. When you optimize these factors, you get stronger molds with better cohesion. This leads to better results in the sand casting process.

Proper sand filling improves mold strength and reduces defects.

Homogeneous mixing and adequate pressing are critical for high-quality sand casting.

You achieve better casting results when you control every step of the sand filling process.

Note: Always check the sand level and packing before moving to the next step. Consistent sand filling supports the entire metal casting process and helps you produce reliable castings.

Compaction Steps

You reach the compaction steps after you fill the flask with sand. This stage is vital in the sand casting process. You use the molding machine to press the sand tightly around the pattern. The goal is to create a mold that is strong, uniform, and ready for casting. You can use different compaction methods, such as jolting, squeezing, or air impact, depending on your molding machine.

When you compact the sand, you control the pressure and the amount of water in the mixture. Studies show that the right compaction pressure increases the relative density of bentonite-bonded green molding sand. The Shapiro-Kolthoff equation helps you understand how compaction pressure relates to density. The Sheppard-McShane strength equation predicts green compression strength with high accuracy. You can use these models to estimate how strong and uniform your mold will be.

Experimental results show that green strength peaks when the moisture-to-bentonite ratio is about 0.33.

The best water content for sand is around 3% by weight.

Uniform compaction and optimal water content are critical for mold strength and uniformity.

Flowability, or how well the sand moves and packs, depends on water content and bentonite ratio.

A new model uses the relative density difference (ΔDr) as an index of flowability, helping you achieve better uniformity.

You want the sand to flow well during compaction, but you also need it to hold its shape. If you use too much water, the sand becomes weak. If you use too little, the sand does not pack tightly. You must find the right balance. Uniform compaction ensures that every part of the mold has the same strength. This step directly affects the quality of your sand casting.

Tip: Always monitor the compaction pressure and water content during the molding process. Small changes can make a big difference in casting quality.

Mold Release

After you finish compacting the sand, you need to release the mold from the pattern. This step is called mold release. You lift the pattern out of the sand carefully to avoid damaging the mold cavity. If you use an automated molding machine, you get more precise and repeatable results.

You must check that the sand mold keeps its shape after you remove the pattern. If the sand collapses or cracks, you may need to adjust the compaction steps or the sand mixture. Proper mold release is important for the sand casting process because it protects the mold cavity. A clean release means you get a smooth surface on your final casting.

Some machines use a synchronous pattern stripping mechanism. This feature helps you remove the pattern smoothly and reduces the risk of defects. You should always inspect the mold after release. Look for cracks, loose sand, or surface flaws. Fix any problems before you move to the next step.

Note: A successful mold release depends on good compaction, the right sand mixture, and careful handling. These factors help you produce high-quality castings.

Core Setting

You use core setting when your casting needs hollow sections or complex shapes. A core is a separate piece made from sand that you place inside the mold cavity. The core creates spaces in the final casting where metal should not flow.

You must handle the core with care. Place it in the mold cavity so it fits tightly and does not move during pouring. You can use core prints or supports to hold the core in place. The sand used for cores often has a different binder or higher strength than the sand in the main mold. This helps the core keep its shape during the sand casting process.

Check the alignment of the core before you close the mold. If the core shifts, the final casting will have defects. Automated molding machines can help you set cores with high precision. This step is important for producing complex castings in sand casting.

Use the right sand and binder for core strength.

Make sure the core fits snugly in the mold cavity.

Inspect the core for cracks or damage before setting it.

Tip: Proper core setting improves the accuracy and quality of your sand casting. Take your time with this step to avoid costly casting defects.

Mold Assembly

You reach the mold assembly stage after you finish core setting. This step brings together all the parts of your sand mold. You align the cope and drag, which are the top and bottom halves of the mold. You make sure the core sits in the right place inside the cavity. Good alignment prevents leaks and casting defects.

You must check that the sand surfaces fit tightly. Gaps or misalignment can let molten metal escape during pouring. You use guide pins or alignment features to help the halves match up. Some foundries use clamps or weights to hold the mold together.

Precise mold assembly plays a big role in reducing casting defects. When you use dry sand molds with clay binders and little water, the mold keeps its shape and resists collapse. This stability lowers the chance of defects from mold movement. Resin-coated sand molds give you even more strength and dimensional accuracy. You get smoother surfaces and fewer problems with mold collapse. Sodium silicate molds also help you make detailed castings with fewer flaws, especially when you need high precision.

Tip: Always inspect the assembled mold for cracks, loose sand, or misalignment before moving to the next step. Careful assembly helps you avoid costly casting errors.

Pouring and Cooling

You move to pouring and cooling after you assemble the mold. You heat the molten metal to the right temperature for your casting. You pour the molten metal into the mold cavity through a sprue or pouring basin. You must pour at a steady rate to avoid splashing or trapping air.

Modern foundries use sensors and data to control pouring and cooling. For example, Ortrander Eisenhütte GmbH, a large green sand casting foundry, collected years of production data. They measured sand temperature, compactability, and the chemical makeup of both the sand and the molten metal. They found that keeping these factors within set limits reduced defects like gas bubbles, sand inclusions, and broken molds.

You need to watch the temperature of both the sand and the molten metal. If the sand is too wet or too dry, you can get defects. If the molten metal is too hot or too cold, you risk problems like cold runs or porosity. Foundries often adjust the water in the sand based on its temperature and moisture. This helps keep the sand at the right level for molding.

After pouring the metal, you let the casting cool inside the mold. Cooling time depends on the size and shape of the casting. If you remove the casting too soon, it can crack or warp. If you wait too long, the sand can stick to the surface. You want to find the right balance for each job.

Note: Keeping pouring and cooling steps under control leads to better casting quality. Use data and regular checks to keep your process stable.

Casting Removal

You reach the casting removal step after the casting cools. You break open the sand mold to get the finished casting out. You use shakeout machines or manual tools to separate the sand from the casting. The sand falls away, and you collect it for reuse in the next molding cycle.

You inspect the casting for defects like cracks, rough surfaces, or extra metal. You remove any sand that sticks to the casting using brushes or blasting machines. You also cut off the sprues and risers, which are the channels used for pouring the metal.

You recycle most of the sand for future molds. You check the sand for moisture, clay content, and grain size before using it again. Good sand management helps you save money and keep your casting process efficient.

Tip: Handle the casting carefully during removal. Quick checks and gentle cleaning help you spot problems early and keep your castings in top shape.

Sand Casting Applications

Typical Castings

You see sand casting used to make many types of metal parts. This method shapes both simple and complex items. You often find sand casting in the production of engine blocks, pump bodies, valve bodies, and manhole covers. These parts need strength and durability. Sand casting gives you the flexibility to create large and heavy castings, such as machine bases and frames. You can also use sand casting for smaller items like gears, shafts, and fittings. Many foundries use sand casting to make custom shapes for decorative fixtures and unique industrial parts. The process works well for both high-volume and custom jobs.

Sand casting lets you create parts with different sizes and shapes. You can make one part or thousands, depending on your needs.

Industry Use Cases

You find sand casting processes in many industries. The automotive industry uses sand casting to make engine blocks, transmission housings, and chassis parts. These parts must be strong and precise. The aerospace sector uses sand casting for turbine blades and structural components. These castings need to be lightweight and reliable. Construction companies use sand casting for manhole covers, drainage systems, and decorative elements. These castings must last a long time and handle heavy loads.

Here is a table showing how different industries use sand casting and what they value most:

You also see sand casting in plumbing, where fittings and valve bodies need good dimensional accuracy and strength. Machinery makers use sand casting for gears and shafts that must last a long time. The Foundry Tools Market report shows that sand casting is a major part of the metal casting process. The demand for sand casting tools keeps growing, especially as industries need more complex and large castings. New technologies, like 3D printing and automation, help you make better molds and improve casting quality.

Manhole covers show the durability of sand casting.

Drainage systems prove its long-lasting performance.

Ornamental fixtures highlight the custom shapes you can achieve.

Cost-effectiveness makes sand casting popular in construction.

Adaptability means you can use sand casting in many industries.

Limitations

You should know that sand casting has some limits. The process can have lower dimensional accuracy than other methods. Sometimes, you see more casting defects, like rough surfaces or weak spots. The molds made in sand casting cannot be stored for long periods. You need to use them soon after making them. Sand casting molds also have lower strength compared to other mold types.

Fluctuations in industries like automotive and construction can affect the demand for sand casting.

High initial investment costs may limit smaller companies from using advanced sand casting machines.

Other molding methods, such as no-bake and investment casting, compete with sand casting for certain jobs.

Environmental concerns, like sand disposal and emissions, require careful management.

Modern foundries use automation, predictive analytics, and environmental safety systems to improve sand casting processes. These advances help you get better results and reduce some of the limits. Feeding and filtration systems can also improve casting yield and lower defects, but they do not remove all the basic limits of sand casting.

Note: Sand casting remains a key part of the metal casting process because it balances cost, flexibility, and performance. You can get great results by understanding both its strengths and its limits.

Advantages

Efficiency

You can boost your foundry’s productivity with green sand molding machines. These machines use automation and smart controls to help you make more molds in less time. You get steady results because the machines keep the process stable. When you use advanced models, you can handle changing casting needs quickly.

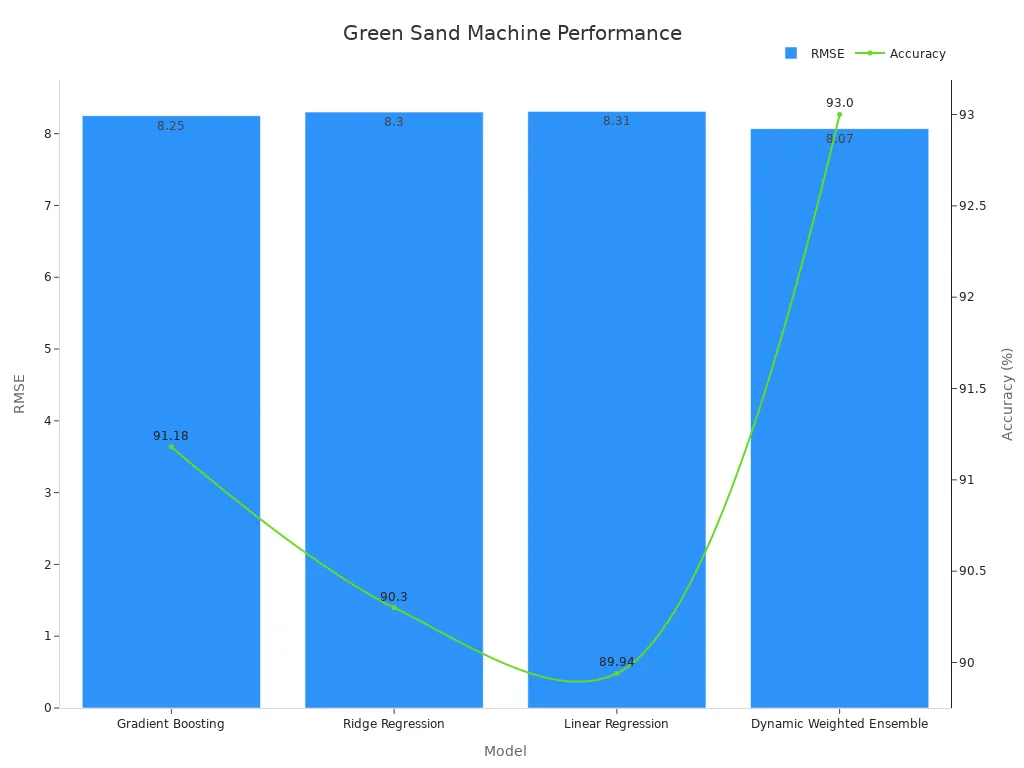

Here is a table that shows how different machine models perform on key efficiency metrics:

You can see that the Dynamic Weighted Ensemble (DWE) model gives the best results. It improves both accuracy and consistency. This means you get fewer errors and more reliable castings.

This chart shows how the DWE model outperforms others in both RMSE and prediction accuracy. You can trust these machines to keep up with modern Industry 4.0 standards.

Quality

You can count on green sand molding machines to deliver high-quality castings. Experts from the American Foundry Society teach you about sand compaction, equipment care, and process control. These lessons help you avoid defects and keep your molds strong.

Researchers have tested green sand molds for strength, permeability, and hardness. They use smart tools like artificial neural networks to predict and control the sand mix. When you follow these best practices, you get molds with the right strength and shape. This leads to castings with smooth surfaces and fewer flaws.

Studies show that adjusting the amount of bentonite and water in recycled sand improves the quality of iron castings. Tests using stereo microscopes and Rockwell hardness checks prove that you get better surface hardness and a stronger microstructure. When you control your sand mix, you make better products every time.

Cost-Effectiveness

You save money when you use green sand molding machines. These machines let you recycle sand, which cuts down on waste and lowers your material costs. Automation helps you use less labor and reduces mistakes, so you spend less fixing problems.

You can reuse green sand many times, making your process more sustainable.

Smart controls and sensors help you spot issues early, so you avoid costly defects.

You can make both small and large batches, which gives you flexibility for different jobs.

Many industries, like automotive and aerospace, use these machines to meet high demand for complex parts.

Companies around the world choose green sand molding because it balances cost, speed, and quality.

Tip: When you invest in modern green sand molding machines, you get a system that pays off through lower costs, better quality, and higher efficiency. You also help the environment by reducing waste and energy use.

Environmental Impact

Modern green sand molding machines help you protect the environment while making high-quality castings. You can lower your foundry’s carbon footprint and save energy by using advanced equipment. These machines use less power and produce fewer harmful emissions than older systems. When you choose a machine with servo control and smart automation, you make your process cleaner and more efficient.

You can see the eco-friendly benefits in the table below:

You help the planet by using less energy and cutting down on carbon emissions. Studies show that switching to modern green sand molding machines can save you almost 9% in energy for each casting. You also reduce carbon emissions by over 11%. If you use composite molding technologies, such as combining sand casting with 3D printing and milling, you make your process even more efficient. These methods help you use resources better and finish jobs faster. You can save more than five hours on each casting compared to old methods.

When you replace organic binders with inorganic ones, you lower the release of harmful gases like BTEX and PAHs. This change makes your foundry safer for workers and better for the environment. Improved molding technologies also give you stronger castings and smoother surfaces. You get better results and help the environment at the same time.

Juneng’s global reach means you can find support and service wherever you operate. Their after-sales network helps you keep your machines running efficiently, so you continue to meet your sustainability goals. By choosing modern green sand molding machines, you take a big step toward a cleaner, greener future for your foundry.

Tip: Every small improvement in your process adds up. When you use advanced molding machines, you help your business and the environment at the same time.

Best Practices

Machine Setup

You set up your green sand molding machine for success by following a clear checklist. Start by reading the machine manual. This helps you understand each part and its function. Place the machine on a flat, stable surface. Check that all bolts and fasteners are tight. Connect the power supply and test the emergency stop button. Make sure the sand hopper is clean and free of old material.

Before you run the machine, inspect the pattern and flask. Look for cracks or wear. Clean the pattern to remove dust or debris. Adjust the pattern alignment using the machine’s guides. Set the compaction pressure according to the type of sand and casting you plan to make. Use the control panel to select the right program for your job.

Tip: Keep a daily log of machine settings and maintenance. This helps you spot problems early and keeps your process consistent.

Sand Quality Control

You get better castings when you control your sand quality. Test the sand before each batch. Measure moisture content with a moisture tester. Aim for about 3% water by weight. Check the clay content using a methylene blue test. Good green sand has the right balance of sand, clay, and water.

Use a table like this to track your sand tests:

Mix the sand well in the muller. Avoid lumps or dry spots. If you see weak molds or rough surfaces, adjust the water or clay. Recycle used sand, but always test it before reuse.

Note: Consistent sand quality leads to fewer casting defects and smoother surfaces.

Safety

You protect yourself and your team by following safety rules. Always wear safety glasses, gloves, and a dust mask. Keep loose clothing and hair away from moving parts. Check that all guards and covers are in place before starting the machine.

Never reach into the machine while it is running. Use lockout procedures when you clean or repair the equipment. Keep the work area clean and free of spills. Store chemicals and binders in labeled containers.

⚠️ Alert: Report any machine faults or injuries right away. Quick action prevents bigger problems and keeps everyone safe.

You have learned how green sand molding machines work and why they matter in foundries. Automation and servo technology help you get better molds with less effort. If you want to improve your casting process, focus on machine setup, sand quality, and safety. Explore new solutions like Juneng’s Servo Molding Machines for more precision and efficiency.

Tip: Upgrading your equipment can help you save time, reduce waste, and boost casting quality.

FAQ

What is green sand in molding?

Green sand is a mix of silica sand, clay, water, and additives. You use it to form molds for metal casting. The term "green" means the sand is moist, not colored.

How does a green sand molding machine improve casting quality?

You get better casting quality because the machine compacts sand evenly around the pattern. Automation helps you control pressure and moisture, which reduces defects and improves mold strength.

Can you reuse green sand after casting?

Yes, you can reuse green sand many times. You need to test and adjust the sand’s moisture and clay content before each cycle to keep mold quality high.

What metals can you cast with green sand molds?

You can cast iron, steel, aluminum, and bronze using green sand molds. This process works well for both ferrous and non-ferrous metals.

How does servo technology help in green sand molding machines?

Servo technology gives you precise control over movement and pressure. You get consistent molds with tight tolerances. This technology also speeds up production and reduces waste.

Is green sand molding safe for the environment?

Green sand molding is eco-friendly. You recycle most of the sand and use less energy with modern machines. Using inorganic binders can further reduce harmful emissions.

What maintenance does a green sand molding machine need?

You should clean the machine regularly, check moving parts, and test safety systems. Inspect sand quality and replace worn patterns. Routine checks help you avoid breakdowns and keep production smooth.

Can you automate the entire green sand molding process?

Yes, you can automate most steps. Modern machines handle sand mixing, mold making, core setting, and even pouring. Automation helps you boost efficiency and reduce manual labor.