Introduction: When High Energy Consumption Becomes an Industry Bottleneck

In many traditional foundry workshops, large horizontal molding lines occupy vast floor space, material handling paths are long, and energy consumption remains stubbornly high. At the same time, environmental regulations are becoming stricter, labor costs continue to rise, and customers increasingly demand stable quality and sustainable production.

The foundry industry has reached a turning point.

In the past, competitiveness was defined by scale and experience. Today, it is driven by green manufacturing, automation, and overall system efficiency. Against this backdrop, the FBO-Vertical Casting System, representing a new generation of vertical molding technology, is emerging as a key solution for the industry’s transformation.

With years of experience in casting equipment R&D, Quanzhou Juneng Machinery Co., Ltd. is providing foundries with a practical and scalable path toward intelligent and environmentally responsible production.

1. Industry Background: The Structural Limits of Traditional Molding Lines

From a production perspective, conventional horizontal molding systems are increasingly unable to meet modern manufacturing requirements.

| Industry Challenge | Typical Issues | Impact on Foundries |

| High Energy Use | Long transfer distances, frequent idle operation | Rising unit production costs |

| Low Space Efficiency | Large mold boxes, scattered layout | Wasted workshop space |

| Environmental Pressure | Dust, waste sand, and noise difficult to control | Increasing compliance costs |

These limitations have prompted foundries to rethink the molding process itself. The question is no longer whether equipment should be upgraded, but whether the entire molding concept should be redefined.

This is where the Vertical Sand Casting Machine enters the picture.

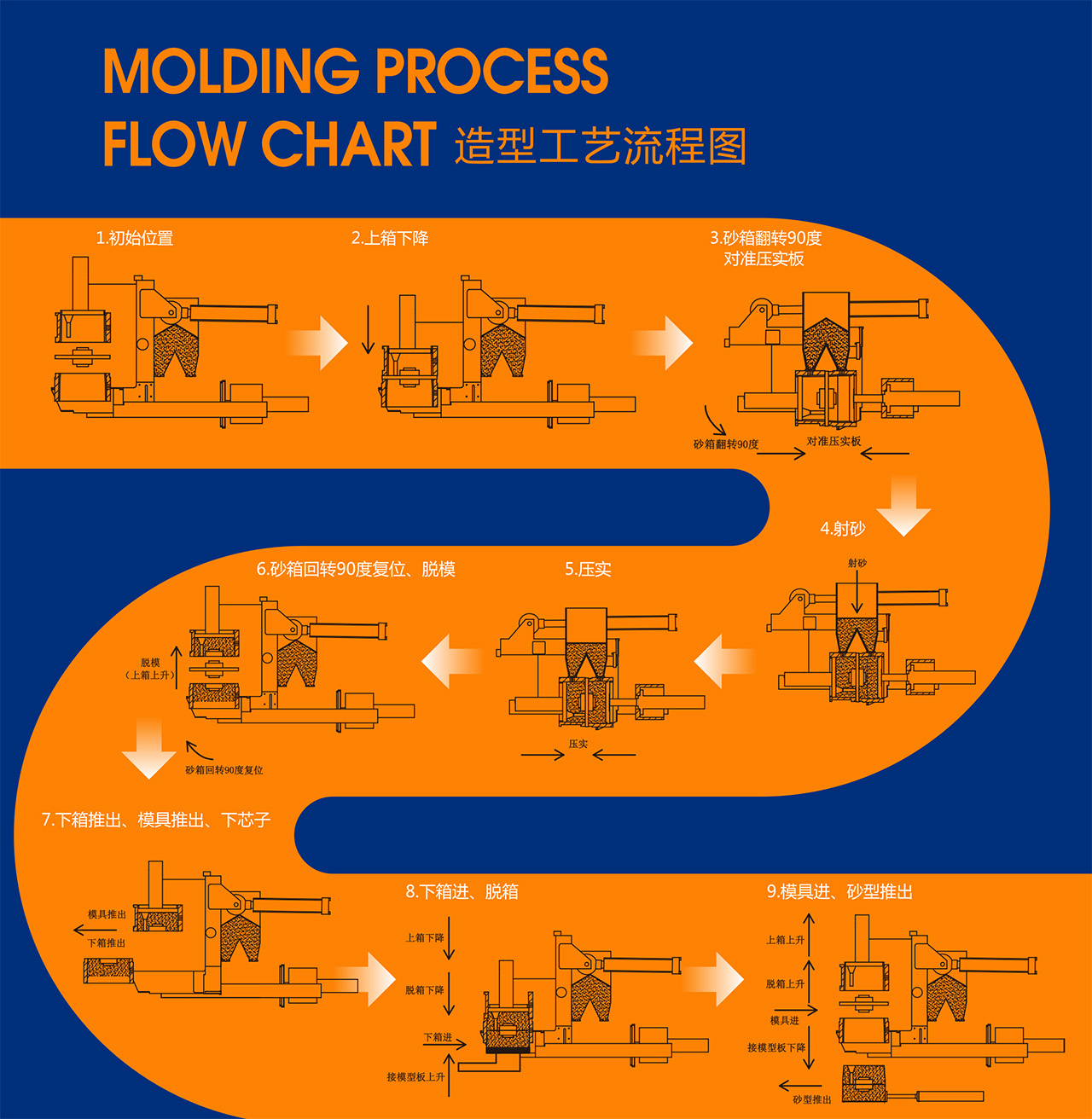

2. The Technical Logic Behind FBO-Vertical: A System-Level Transformation

2.1 From Horizontal Layouts to Vertical Manufacturing

Unlike traditional horizontal parting lines, the FBO-Vertical Casting System adopts a vertical parting structure, where molds are arranged upright in a continuous sequence. This structural change delivers a series of system-wide advantages:

Much higher mold density

Significantly shorter conveying paths

Over 30% reduction in floor space requirements

As a result, the Vertical Sand Casting Machine is particularly well suited for high-output foundries facing space constraints.

2.2 Automation as the Foundation of Quality Stability

Within the FBO-Vertical system, molding is fully controlled by an Automatic Molding Machine. Key parameters such as sand shooting, compaction force, and mold separation are digitally programmed and precisely repeated in every cycle.

This brings three major benefits:

Highly consistent mold hardness

Improved dimensional repeatability

Noticeably lower defect rates

For foundries pursuing stable, large-scale production, this level of automation is essential.

3. The Core of Green Manufacturing: Energy Savings, Emissions Reduction, and Material Efficiency

3.1 Energy Efficiency Starts with Structural Design

Thanks to its compact vertical layout, the FBO-Vertical system significantly reduces unnecessary material movement, waiting time, and mechanical repetition. Combined with servo drives and variable-frequency control, overall energy consumption can be reduced by 15–25%.

This is a defining feature of true Green Foundry Equipment—achieving energy savings through intelligent process design rather than post-process compensation.

3.2 Higher Material Utilization: Making Every Grain of Sand Count

Traditional molding lines often suffer from excessive sand loss due to long return paths and loose mold arrangements. In contrast, the FBO-Vertical system shortens the sand circulation loop, improving reuse efficiency and reducing waste.

In real production environments, foundries typically achieve:

Over 20% reduction in new sand consumption

Substantially lower waste sand discharge

This is a practical embodiment of Environmental Casting Solutions at the material level.

3.3 Environmental Control by Design, Not by Add-On

The vertical structure of the FBO-Vertical system is inherently suited for enclosed designs. Sand mixing, molding, and conveying can be more easily sealed and connected to centralized dust collection and noise control systems.

As a result, the system aligns naturally with modern Green Foundry Equipment standards, making environmental compliance easier and more reliable.

4. Performance Comparison: FBO-Vertical vs. Traditional Molding Lines

| Item | Traditional Horizontal Line | FBO-Vertical Casting System |

| Floor Space | Baseline 100% | ↓ 30–40% |

| Output per Line | Baseline | ↑ 25–35% |

| Energy Consumption | High | ↓ 15–25% |

| Mold Consistency | Operator-dependent | Highly consistent |

| Automation Level | Semi-automatic | Fully automatic |

| Environmental Adaptability | Retrofit required | Built-in compliance |

The data clearly shows that the Vertical Sand Casting Machine represents not just an equipment upgrade, but a fundamental shift in production philosophy.

5. Typical Applications: Who Benefits Most from FBO-Vertical?

The FBO-Vertical system is especially suitable for:

Automotive and machinery component foundries with batch production

Plants constrained by limited workshop space

Traditional foundries facing urgent environmental upgrades

In these scenarios, the combination of Automatic Molding Machine technology and Environmental Casting Solutions enables higher output with fewer workers and greater operational stability.

6. Frequently Asked Questions (FAQ)

Q1: Is the FBO-Vertical system suitable for small and medium-sized foundries?

Yes. The system supports modular configurations and scalable capacity. Typical payback periods range from 2 to 3 years.

Q2: Does it require major factory reconstruction?

No. The compact vertical layout often makes it easier to install in existing facilities.

Q3: Is maintenance complicated?

Not at all. The system uses standardized modules, long service intervals, and simplified daily maintenance.

Q4: Are there limitations on casting types?

The FBO-Vertical Casting System is suitable for most small to medium iron, ductile iron, and non-ferrous castings.

Q5: Can environmental and energy data be tracked?

Yes. The system supports data collection for energy use and operational performance, facilitating environmental and efficiency management.

7. Industry Outlook: Vertical Molding as a Global Trend

Globally, vertical molding technology is gaining rapid adoption. In Europe and Japan, the Vertical Sand Casting Machine has become a standard configuration for mid- to high-end foundry production lines.

With stricter environmental regulations and rising labor costs, the combination of Green Foundry Equipment and automated molding is increasingly becoming the preferred choice for both new plants and upgrades.

Conclusion: From Equipment Upgrades to a New Manufacturing Mindset

The future of the foundry industry is not just about producing more—but about producing cleaner, smarter, and more sustainably.

The FBO-Vertical Casting System represents more than a machine; it embodies a forward-looking manufacturing philosophy. Through continuous innovation in Automatic Molding Machine technology and Environmental Casting Solutions, Quanzhou Juneng Machinery Co., Ltd. is helping foundries transition from traditional operations to intelligent, green manufacturing.

📣 Call to Action

If you are considering:

Increasing output without expanding floor space

Reducing energy consumption while meeting environmental standards

Achieving more stable production with fewer operators

We invite you to contact Juneng Machinery to apply for a visit to an FBO-Vertical demonstration line or request a Vertical Molding ROI Evaluation Report.

Make casting greener. Make manufacturing smarter.

Juneng Machinery — Building future-ready solutions for the global foundry industry.