You need the right Sand Casting Equipment for good results in your foundry. Here are the seven important tools you should use:

Molding flasks

Ramming tools

Pattern equipment

Core making machines

Melting furnaces

Pouring and handling tools

Shakeout and cleaning systems

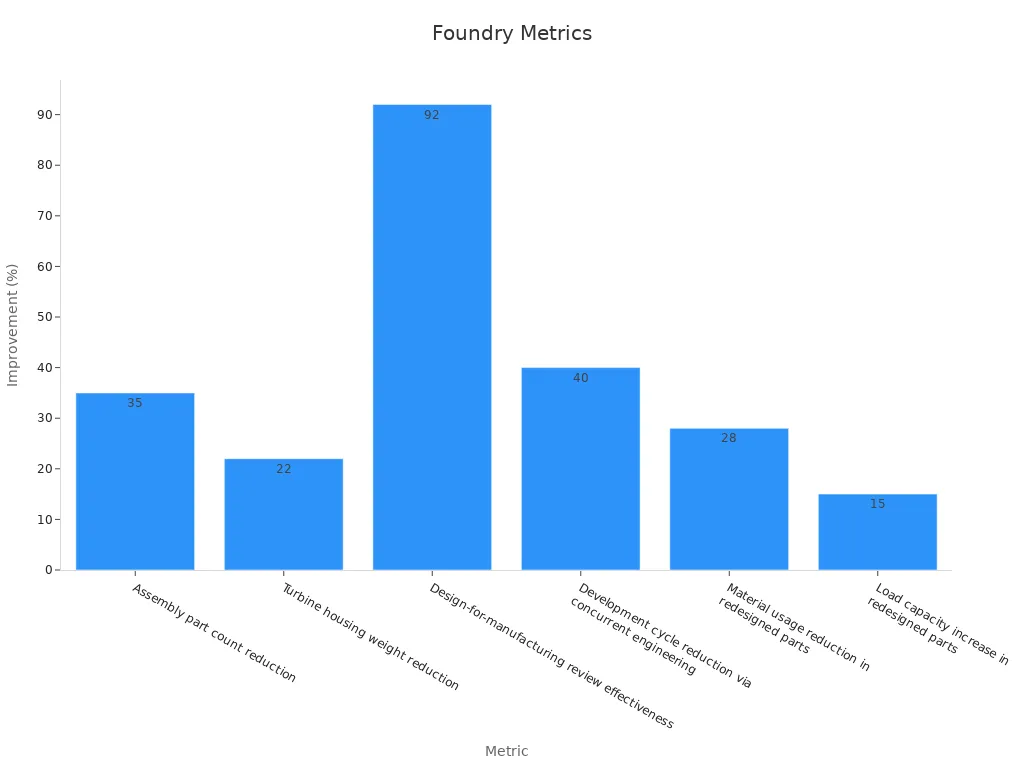

Each tool helps make fewer mistakes and better parts. These tools also help you work faster and do the same thing every time. Modern equipment saves time, costs less, and makes things more exact. You can see how these changes help performance:

Key Takeaways

Use the right molding flasks to keep sand molds steady. This helps make sure castings are correct each time. Ramming tools pack sand tightly. This stops weak molds and makes castings better. Pick pattern materials that fit your needs. This helps you get exact parts with no mistakes. Core making machines make hollow spaces inside castings. This makes them stronger and adds detail. Pick melting furnaces for your metal type and batch size. This melts metal safely and works well. Pouring and handling tools keep workers safe. They help pour hot metal smoothly and stop mistakes. Shakeout and cleaning systems take away sand and finish castings. This makes products better and easier to check. Using all seven equipment types in order helps foundries work faster and safer. It also lowers mistakes.

Molding Flasks

Purpose

You need molding flasks to hold and support the sand mold during the casting process. These frames keep the sand in place while you shape the mold and pour the molten metal. Without a sturdy flask, the sand mold can break or shift. You use molding flasks to make sure your castings have the right shape and size every time.

Tip: Always check your molding flask for cracks or damage before each use. A damaged flask can ruin your mold and waste materials.

Types

You can choose from several types of molding flasks, each designed for specific casting needs. The most common types include:

Cope and Drag Flasks

The cope is the top part of the flask.

The drag is the bottom part.

You stack them together to form the complete mold.

Snap Flasks

These flasks have hinges and latches.

You can open and close them quickly, which saves time during production.

Tight Flasks

These flasks do not open.

You use them for molds that need extra support or for automated molding lines.

You should select the flask type that matches your casting process and production volume. The right choice helps you work faster and reduces errors.

Role in Mold Stability

Molding flasks play a key role in keeping your sand mold stable. When you pack sand into the flask, it forms a solid structure around your pattern. The flask holds the sand tightly, so it does not move or collapse when you pour the metal. This stability means you get castings with accurate shapes and fewer defects.

If you use the wrong flask or a damaged one, your mold can shift or break. This leads to poor-quality castings and wasted materials. Reliable molding flasks help you maintain consistency and improve your overall results with Sand Casting Equipment.

Note: Investing in high-quality molding flasks pays off in the long run. You will see fewer defects and better product quality.

2. Ramming Tools

Function

You use ramming tools to pack sand tightly around the pattern inside the molding flask. These tools help you create a firm and even mold. When you press the sand down, you remove air pockets and make the mold strong. This step is important because loose sand can cause the mold to break or shift when you pour the metal. Ramming tools give you control over how hard you pack the sand. You can make sure every part of the mold has the same strength.

Tip: Always ram the sand in layers. This method helps you avoid weak spots and keeps the mold shape accurate.

Types

You can choose from several types of ramming tools. Each type works best for a different part of the mold or a specific job. Here are the most common types you will find in modern foundries:

Hand Rammers:

You use these simple tools for small molds or detailed work. They have a flat end and a rounded end. The flat end packs large areas, and the rounded end reaches tight spots.Pneumatic Rammers:

These tools use air pressure to pack sand quickly. You use them for large molds or high-volume production. Pneumatic rammers save time and reduce worker fatigue.Mechanical Rammers:

You find these in automated Sand Casting Equipment setups. They use motors to ram sand with consistent force. Mechanical rammers help you get the same results every time.

You should select the ramming tool that matches your mold size and production needs. The right tool helps you work faster and with better results.

Impact on Mold Quality

Ramming tools play a big role in the quality of your final casting. When you pack the sand well, you get a mold that holds its shape during pouring. Good ramming stops sand from falling into the molten metal. This means you get fewer defects and a smoother surface on your cast parts. If you use the wrong tool or do not ram the sand enough, you risk weak molds and poor-quality castings.

Note: Investing in the right ramming tools improves your workflow and product quality. You will see fewer mistakes and better results with every pour.

3. Pattern Equipment

Materials

You need to choose the right material for your pattern equipment. The material you select affects the durability, cost, and finish of your molds. Here are the most common materials you will find in modern foundries:

Wood

Wood patterns are easy to shape and cost less. You use them for small production runs or prototypes. They wear out faster than other materials.Metal

Metal patterns, such as aluminum or steel, last much longer. You use them for high-volume production. They give you a smooth surface and hold their shape well.Plastic

Plastic patterns are lightweight and resist moisture. You use them when you need a balance between cost and durability.

Tip: Always match the pattern material to your production needs. For long runs, metal saves you time and money.

Use in Mold Creation

You use pattern equipment to shape the sand mold before casting. The pattern acts as a model for your final part. You press the pattern into the sand inside the molding flask. When you remove the pattern, it leaves a cavity that matches the shape of your part.

Follow these steps to use pattern equipment in mold creation:

Place the pattern in the molding flask.

Pack sand tightly around the pattern using ramming tools.

Carefully lift the pattern out, leaving a clean cavity.

Inspect the mold for any defects or loose sand.

Note: Clean your pattern before each use. Dirt or damage can cause defects in your mold.

Effect on Accuracy

Pattern equipment plays a big role in the accuracy of your castings. If you use a well-made pattern, you get parts with the right size and shape every time. Poor patterns lead to defects, rough surfaces, or parts that do not fit.

You can improve accuracy by:

Using high-quality materials for your patterns.

Checking patterns for wear or damage before each use.

Storing patterns in a dry, safe place.

A precise pattern helps you get the most out of your Sand Casting Equipment. You will see fewer mistakes and better results in your finished products.

Alert: Never ignore small defects in your pattern. Even tiny flaws can ruin an entire batch of castings.

4. Core Making Machines

Core Types

Core making machines help you make cores for hollow spaces. These cores create holes or passages inside your castings. There are different core types, and each one is good for certain jobs:

Sand Cores: You make these with sand and glue. They work for most casting jobs.

Shell Cores: You use a hot metal pattern and special sand. These cores are smooth and strong.

Metal Cores: You pick these when you need the core to last longer or use it again.

Tip: Pick the right core for your casting job. The best core helps you make light parts and exact shapes. This is important for things like engine blocks, pumps, and valve bodies.

Machine Functions

Core making machines do the work of shaping and hardening cores. They also help take the core out safely. Here is what these machines do:

Core Shooting: The machine pushes sand and glue into a box fast. This fills every part of the mold.

Curing: The machine uses heat or chemicals to make the core hard. This keeps the shape strong.

Ejection: The machine takes the finished core out of the box without breaking it.

Some machines use computer programs like Magma C+M and FLOW-3D CAST. These programs show how sand moves and hardens in the box. You can find problems early and fix them for better results. Studies show that these programs help you get better core quality and strength. This is very important for tricky castings.

Importance for Complex Castings

You need core making machines for castings with hard shapes inside. These machines help you make exact cores for the inside of your part. Good cores make your casting strong and work well.

You can stop problems like holes and weak spots by using good machines.

Research shows that better cores and molds make stronger castings.

You can make lighter parts and better fluid flow in things like engines and pumps.

Note: Buying new core making machines as part of your Sand Casting Equipment helps you meet tough quality rules and do hard jobs with confidence.

5. Melting Furnaces

Furnace Types

You need the right melting furnace to heat metal. Each furnace type works best for certain metals. Some furnaces are better for big jobs, others for small ones. Here are the main types you will see in foundries:

Cupola Furnace

You use this furnace to melt cast iron. It burns coke as fuel and is good for big batches.Induction Furnace

This furnace uses electricity to melt metal. It melts metal fast and clean with less pollution. You can use it for steel, iron, and other metals.Crucible Furnace

You use this furnace for small batches or special metals. It heats a pot that holds the metal.Electric Arc Furnace

This furnace melts steel with electric arcs. You can control the heat very well.

Tip: Pick your furnace by the metal you need to melt and how much you want to make.

Melting Process

You must follow the right steps to melt metal safely. Here is a simple way to melt metal in your foundry:

Load the Furnace

Put the metal and any needed additives into the furnace.Start Heating

Turn on the furnace and start heating. Watch the temperature all the time.Monitor the Melt

Use tools to check the heat and the metal’s look. Take out any slag or dirt from the top.Tap or Pour

When the metal is hot enough, tap the furnace or pour the metal into a ladle.

Note: Always use the right heat for your metal. Too much heat can hurt the metal or the furnace.

Modern Sand Casting Equipment can help you work better. Automated controls and sensors keep the process safe and correct.

Safety

You must always think about safety with melting furnaces. Hot metal and high heat can cause bad injuries. Here are some key safety steps you should follow:

Wear gloves, face shields, and special clothes for heat.

Stay back from the furnace when it is on.

Use tongs and ladles made for high heat.

Check all equipment for damage before you use it.

Keep fire extinguishers and exits clear.

⚠️ Alert: Never leave a furnace alone while it is running. Always follow your foundry’s safety rules.

You keep yourself and your team safe by following these steps. Safe melting helps you avoid accidents and keeps your foundry working well.

6. Pouring and Handling Tools

Pouring and handling tools help you move and pour molten metal safely and accurately. You need these tools to keep your foundry running smoothly and to protect your team from harm. Using the right tools also helps you make better castings with fewer defects.

Crucibles

You use crucibles to hold and melt metal before pouring it into the mold. The type of crucible you choose affects the quality of your casting. Clay-graphite crucibles work well in oil-fired furnaces. They help you keep the right temperature and reduce slag and contamination. You should always use clean, dry crucibles to avoid moisture and gas-related defects.

Tip: Always inspect your crucible for cracks before each use. A damaged crucible can break and spill hot metal, causing serious injuries.

You can find crucibles in different shapes and sizes. Pick the one that fits your furnace and the amount of metal you need to melt. Using the right crucible helps you control the melting process and keeps your castings clean.

Tongs and Ladles

You need tongs and ladles to move hot crucibles and pour molten metal into molds. Tongs must fit the crucible well. A good fit helps you grip the crucible safely and prevents accidents. You use ladles to scoop and pour the metal. Pouring ladles should be clean and dry to prevent moisture from causing dangerous splashes.

Here are some best practices for tongs and ladles:

Use tongs designed for your crucible size.

Hold the ladle close to the mold sprue to reduce gas absorption and agitation.

Skim slag from the ladle before pouring to keep your casting free of defects.

Use special rods or tongs to add deoxidizers like magnesium safely.

Note: Always check your tongs and ladles for wear or damage. Replace them if you see any cracks or weak spots.

Pouring Safety

Pouring molten metal is one of the most dangerous steps in sand casting. You must follow strict safety rules to protect yourself and your team. Wear heat-resistant gloves, face shields, and protective clothing. Never rush the pouring process. Rapid and controlled pouring helps you fill the mold completely and prevents defects.

Follow these safety steps during pouring:

Use pouring basins or cups made from refractory materials for steel castings. These resist erosion and keep the mold intact.

Keep all tools dry and clean to avoid steam explosions.

Remove risers and gates at the right temperature to prevent cracks in your casting.

Always keep fire extinguishers nearby and know your emergency exits.

⚠️ Alert: Never pour metal alone. Always have another person nearby in case of an emergency.

Using the right pouring and handling tools as part of your Sand Casting Equipment helps you work safely and produce high-quality castings. You reduce the risk of accidents and improve your operational success.

7. Shakeout and Cleaning Systems

Shakeout Process

You need to remove the sand from your casting after the metal cools. This step is called the shakeout process. You can use mechanical shakeout machines for this job. These machines vibrate or shake the mold to break up the sand and free the casting. You save time and reduce manual labor with a good shakeout system.

Vibratory shakeout machines: These use strong vibrations to loosen sand.

Rotary drum shakeouts: These spin the mold and let sand fall away.

Grid shakeouts: These use a metal grid to separate sand from castings.

Tip: Always let the casting cool before starting the shakeout. Hot castings can crack if handled too soon.

A reliable shakeout process helps you recover sand for reuse. You also protect your castings from damage during removal.

Cleaning Tools

After shakeout, you need to clean the casting surface. You can use different cleaning tools to remove leftover sand, scale, and small defects. The right tools help you get a smooth finish and prepare the casting for inspection or further work.

Here are some common cleaning tools you might use:

Wire brushes: These remove loose sand and scale from the surface.

Shot blasting machines: These shoot small steel balls at the casting to clean it quickly.

Grinders and files: These help you smooth rough spots and remove sharp edges.

Air jets: These blow away dust and fine sand.

Note: Always wear safety glasses and gloves when using cleaning tools. You protect yourself from flying debris and sharp edges.

Product Quality

You improve product quality with a strong shakeout and cleaning system. Clean castings have fewer defects and look better. You also make inspection and finishing easier. If you skip or rush these steps, you risk leaving sand or scale on your parts. This can cause problems in later stages or even lead to rejected parts.

Clean castings pass quality checks more often.

You reduce the need for rework or repairs.

Customers trust your foundry when you deliver clean, accurate parts.

A modern Sand Casting Equipment setup includes advanced shakeout and cleaning systems. You boost efficiency and raise your product standards with the right tools.

✅ Pro Tip: Invest in automated cleaning systems if you want to handle large volumes and keep quality high.

Sand Casting Equipment Integration

Workflow

All your equipment must work together for sand casting to go well. When you use all seven types of Sand Casting Equipment, you make a clear plan. First, you get the pattern ready and put it in the molding flask. Then, you use ramming tools to press the sand down tight. Core making machines help you add tricky shapes inside the mold. Melting furnaces heat the metal until it is ready. Pouring and handling tools help you move and pour the hot metal safely. After the metal cools, shakeout and cleaning systems take away the sand and finish the casting.

If you follow these steps in order, you make fewer mistakes. Each tool helps with the next step, so your team always knows what to do.

Efficiency

Your foundry works better when you use the right mix of equipment. When you set up everything to work together, you save time and need fewer workers. Modern Sand Casting Equipment can do many jobs by itself, so you can finish more orders with less help.

Here is a table that shows how using all the equipment together helps your foundry:

You get fewer mistakes, faster work, and less waiting. Your team can work safer and use their time better.

Quality

You make better products when you use all seven tools in the right order. Each tool helps you control the job and stop common problems. Molding flasks and ramming tools keep the mold strong. Pattern equipment and core making machines help you get the right shape. Melting furnaces and pouring tools let you control the heat and flow. Shakeout and cleaning systems clean and smooth the finished part.

When you use all the equipment together, your castings are always good. Customers trust your foundry when you give them clean, strong, and exact parts.

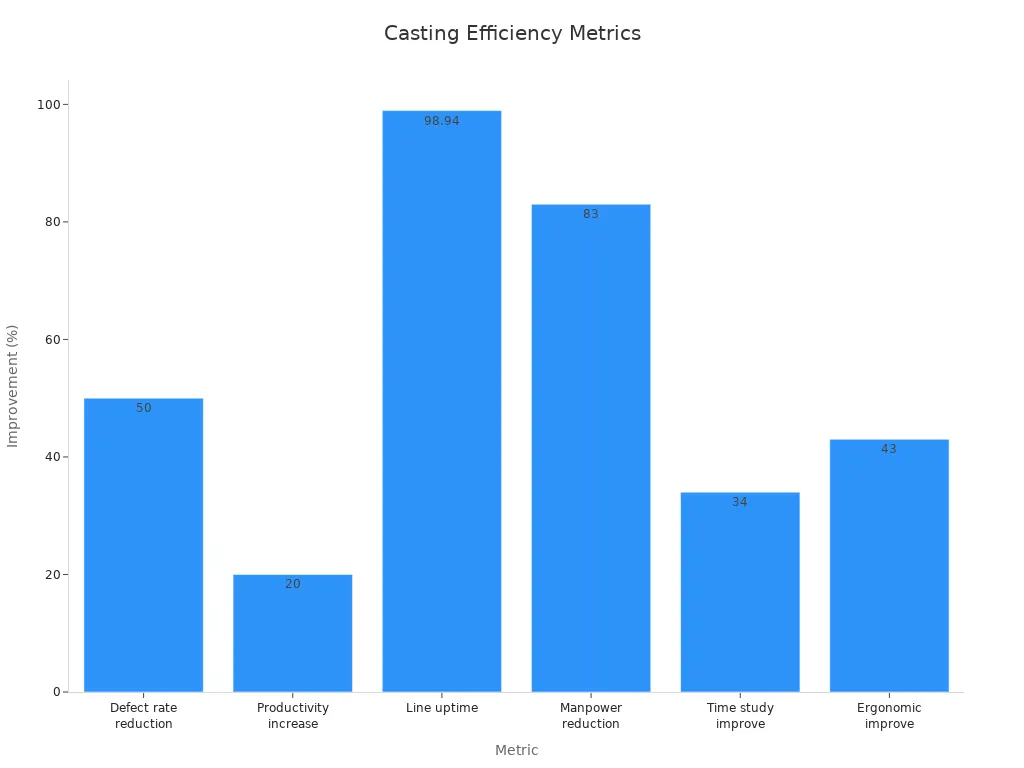

You need every type of Sand Casting Equipment to help your foundry run well and make good castings. Using the right tools means you get fewer mistakes, better results each time, and safer work. When foundries use new equipment, they get more good parts and fewer bad ones, like you can see in the chart below:

Automation and digital tools let you finish jobs faster and save money.

Cleaner sand and better control help you get the same good results every time.

Look at your tools often and choose the best equipment for your foundry’s needs.

FAQ

What is the most important sand casting equipment for beginners?

Start with molding flasks and ramming tools. These help you make strong molds. Pattern equipment helps your first castings turn out right.

How often should you inspect your sand casting equipment?

Check your equipment before every work shift. Look for cracks or damage. Regular checks help stop accidents and keep your castings good.

Can you reuse sand in sand casting?

Yes, you can use sand again if you clean it well. Shakeout and cleaning systems remove dirt and debris. Reusing sand saves money and cuts down on waste.

What safety gear do you need for sand casting?

Wear gloves that resist heat, face shields, and special clothes. This gear keeps you safe from burns, splashes, and flying pieces.

How do you choose the right melting furnace?

Pick a furnace by the kind of metal and how much you need to melt. Induction furnaces are good for clean, fast melting. Cupola furnaces work best for big iron jobs.

Why do you need core making machines?

Core making machines help you make tricky shapes inside castings. They make your parts more exact and let you create hollow or detailed pieces.

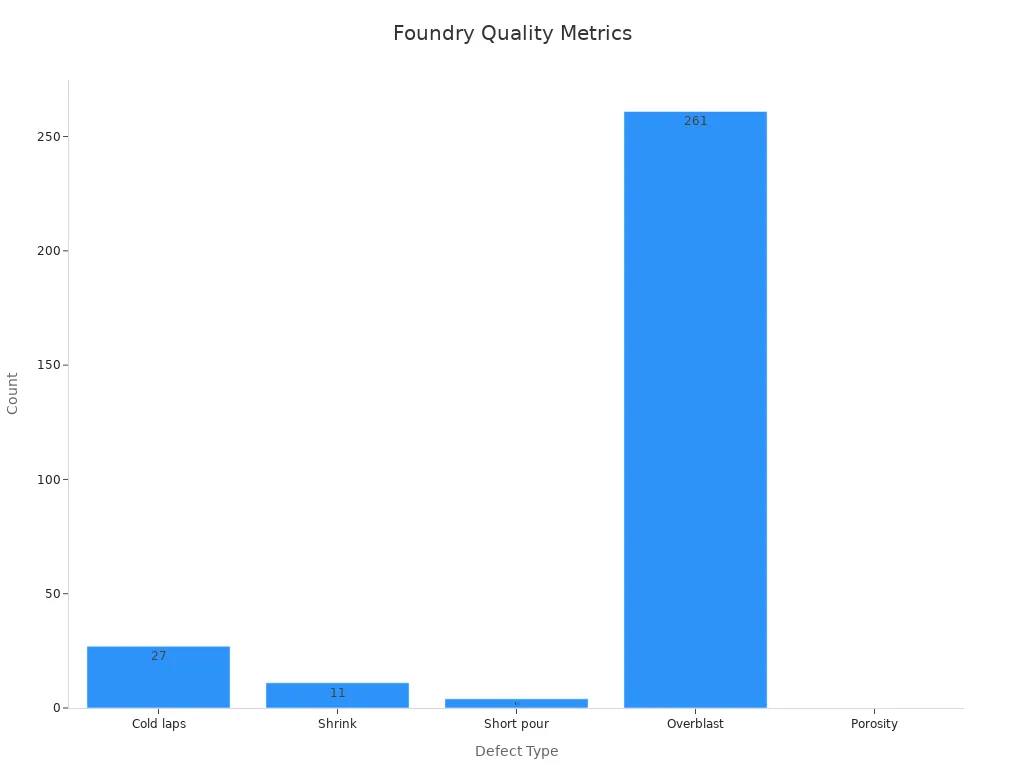

What causes defects in sand castings?

Defects can happen from loose sand, bad ramming, or broken patterns. Using the right tools and following good steps helps stop these problems.

How does automation improve sand casting?

Automation makes work faster and cuts down on mistakes. You get the same results each time and work is safer. Automated tools also mean you need fewer workers.