Sustainable manufacturing is very important today, and green sand casting offers several advantages for saving energy and protecting the environment. Approximately 42% of metal castings worldwide use this method, highlighting its widespread use in factories. The advantages of green sand casting include the ability to reuse sand multiple times, reducing the need for constant mining. It also produces less waste since molds can be reused, and it requires less energy compared to other casting methods, resulting in lower pollution levels.

Key Takeaways

Green sand casting can make many sizes and shapes of parts. This makes it useful for different industries. It also helps cut down on waste.

This method costs less because it uses simple materials. The tools are cheaper too. This helps companies save money from the start to big production.

You can use green sand casting with many metals and alloys. This lets you change things quickly. It is used in many industries.

Green sand casting uses less energy because mixing is fast. Automation also helps save power. This lowers energy bills and helps the planet.

Sand and other materials can be used again in green sand casting. This means less waste goes to landfills. It makes manufacturing cleaner and better for the earth.

1. Versatility

Green sand casting is very flexible. You can use it to make many different parts. This makes it popular in many industries. It helps companies make only what they need. This cuts down on waste and saves resources.

Size Range

Green sand casting can handle almost any size or weight.

It can make castings from a few ounces up to 7,000 pounds.

You can create thin-walled parts as slim as 0.09 inches. You can also make thicker parts with no limit.

It works for both small and large production runs.

You can put several mold cavities in one mold to make more parts at once.

Different molding methods help you adjust for size and weight.

You can change mold thickness without changing flask size. This helps you use materials better.

Tip: Green sand casting equipment lets you switch part sizes fast. This makes your production line more flexible.

Complex Shapes

Green sand casting can make complex shapes and detailed designs.

It can create simple blocks or parts with curves and holes.

You can change patterns and mold designs quickly for special projects.

This means you can help many industries, like automotive, aerospace, and construction, using the same equipment.

Green sand casting uses safe, recyclable materials. You can reuse the sand many times. This lowers waste and saves new materials. Its flexibility gives you more design choices and helps the environment. These benefits make green sand casting a good choice for sustainable manufacturing.

2. Cost Advantages

Green sand casting offers you clear cost advantages in manufacturing. You can use simple, readily available materials like sand, clay, and water. This keeps your production costs low from the start. When you choose green sand casting equipment, you avoid the high expenses that come with other casting methods.

Lower Tooling Costs

You save money on tooling because green sand casting uses patterns and coreboxes that cost much less than the dies and setups needed for investment casting or die casting. Look at the table below to see how much you can save:

You can see that green sand casting tooling costs are about 80% to 90% lower than investment casting. This means you can start new projects or make changes without a big investment. Companies like Quanzhou Juneng Machinery Co.,Ltd. provide advanced green sand casting equipment that helps you keep these costs down. Their solutions let you switch patterns quickly and reduce setup time, which saves even more money.

Mass Production Savings

Green sand casting equipment works well for both small batches and large production runs. You can use it for rapid prototyping because the molds are easy to change. For example, with 3D printing, you can make new patterns in days instead of weeks. This cuts your lead time by over 60% and reduces costs by about half. You can test new designs quickly and move to full production without wasting time or money.

When you scale up, green sand casting still gives you savings. Companies have used this process to cut costs by 10% or more, as seen in real-world case studies. For example, Dotson Iron Castings used green sand casting to make cab mount brackets for trucks and saved money by automating their process. Goldens’ Foundry and Machine Co. improved product durability and reduced costs by switching to green sand casting for their cooker components.

Tip: Green sand casting equipment from trusted suppliers like Quanzhou Juneng Machinery Co.,Ltd. helps you control costs at every stage, from prototyping to mass production.

You get the advantages of low tooling costs, fast setup, and flexible production. This makes green sand casting a smart choice for manufacturers who want to save money and stay competitive.

3. Material Flexibility

Green sand casting lets you use many metals and alloys. This helps you make parts for lots of industries. You can use it for cars, machines, and marine equipment. The process works for simple shapes and also for complex ones. Manufacturers like it because they can change what they make easily.

Multiple Alloys

Green sand casting works with many types of metals. Here are some alloys you can use:

Aluminum Bronze: It does not rust easily. It works well in seawater. It is safe in places where sparks are dangerous.

Manganese Bronze: It is very strong. It is good for heavy parts. It is cheaper to use in sand casting.

Tin Bronze: It is strong and does not wear out fast. It is good for gears, bearings, and piston rings.

Silicon Bronze: It is used for pumps and valves. It does not get damaged by chemicals or liquids. It is good for making detailed shapes.

You can use green sand casting for iron, steel, aluminum, and copper alloys. You can switch between these metals quickly. This saves you time and money.

Note: Some metals that need high heat may need other casting methods. Most common metals work well with green sand casting.

Application Range

Green sand casting helps you make parts for many industries. You can use it for small or big jobs. Here is a table that shows where you can use green sand casting:

You can use one process for many different needs. Green sand casting helps you make parts for cars, machines, and city projects. You can make simple or complex shapes. You can make lots of parts or just a few. This helps your business grow and change when needed.

4. Energy Efficiency

Green sand casting equipment helps you use less energy. You can make more parts in less time. This saves electricity and helps the planet.

Fast Production

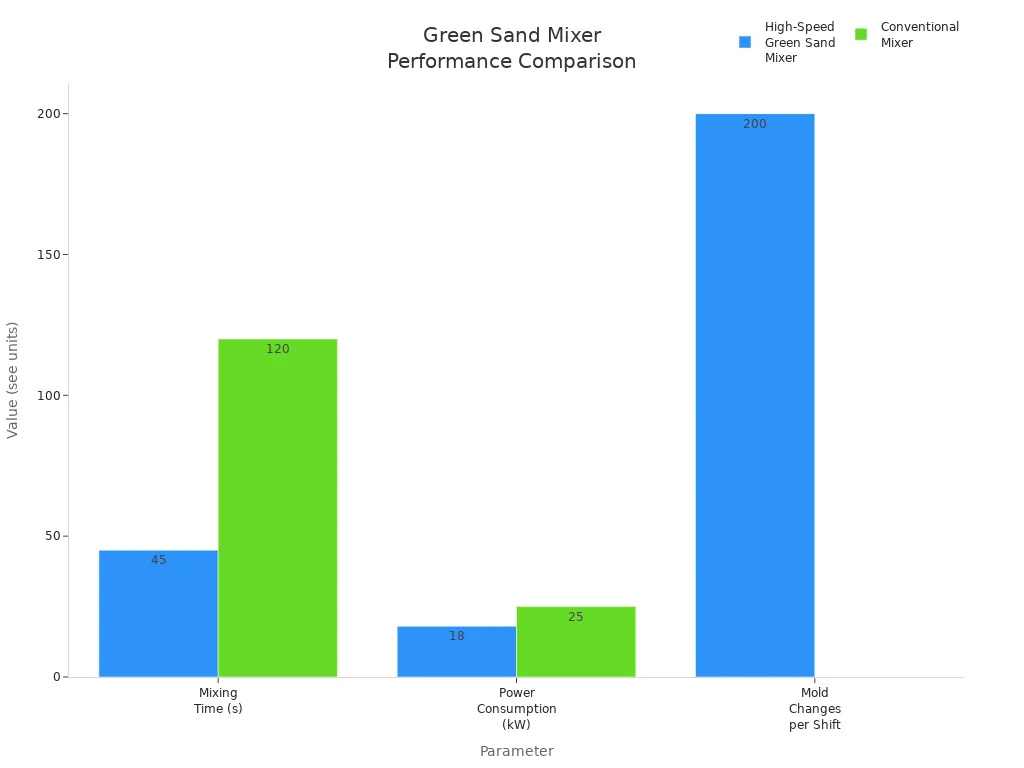

High-speed green sand mixers work very quickly. They mix sand fast and evenly. You get a smooth mix in less than two minutes. This means you can change molds 200 to 400 times in one shift. You use less power and fewer materials. The table below shows how fast production saves energy:

You use less energy for every ton of sand. Precision dosing means you use less binder and water. You also throw away less sand, up to 40% less. These things help you save money and protect nature.

Tip: If you upgrade to high-speed mixers, you can make more parts and pay less for energy.

Automated Processes

Automation makes green sand casting even better. You get good results with less work. Here are some ways automation saves energy:

Automated sand mixing and molding keeps things fast and steady.

Robotic pouring spreads metal evenly, so you get fewer mistakes.

Energy-saving motors use only the power you need.

Heat recovery systems take waste heat and use it again.

Machines like the VIBRA-DRUM® do casting, cleaning, and cooling at once.

Two-mass drive systems use much less energy than old systems.

Automated controls and sensors keep sand quality high and cut waste.

Automated binder dispensing means fewer mistakes and less waste.

New technology like 3D printing and sand mold milling also saves energy. You can design molds that use less material and make less pollution. Additive manufacturing-assisted sand casting lowers global warming by over 30%. You also make less acid and fewer toxins, so it is safer for people and nature.

Note: Using advanced green sand casting equipment and automation gives you more control, less waste, and better energy use.

You get faster production, lower energy bills, and a cleaner factory. These changes make green sand casting a smart choice for the planet.

5. Reduced Waste

Minimal Scrap

You want to make as little scrap as possible in your foundry. Green sand casting helps you do this well. If you control your process, you get about 5% scrap. Sometimes, scrap can go up to 10% when starting or if things are hard. If you manage things carefully, you can keep scrap under 3%. This means you waste less metal and save more money.

Here is a table that shows scrap rates for different casting methods:

Tip: You can lower your scrap by using new green sand casting equipment and keeping your process steady.

Efficient Raw Material Use

Green sand casting lets you use your materials smartly. You can use the same sand over and over. You do not need to buy new sand for every mold. You also save clay, coal dust, and water because you recycle them.

You can add recycled scrap iron or steel to your metal mix. This means you need less new metal.

You can reuse core and molding sands, which are a big part of foundry waste.

You can use sand from nearby, so you do not need to ship it far.

You can recycle water when you prepare sand, which saves even more.

You can use advanced green sand casting equipment to make your gating system better and have fewer casting problems.

Green sand casting equipment helps you use less and waste less. You get more parts from the same amount of material. You also help the earth by making less landfill waste and saving natural resources.

Note: When you use green sand casting, you help the planet by using every bit of material wisely.

6. Recyclability

Sand Reuse

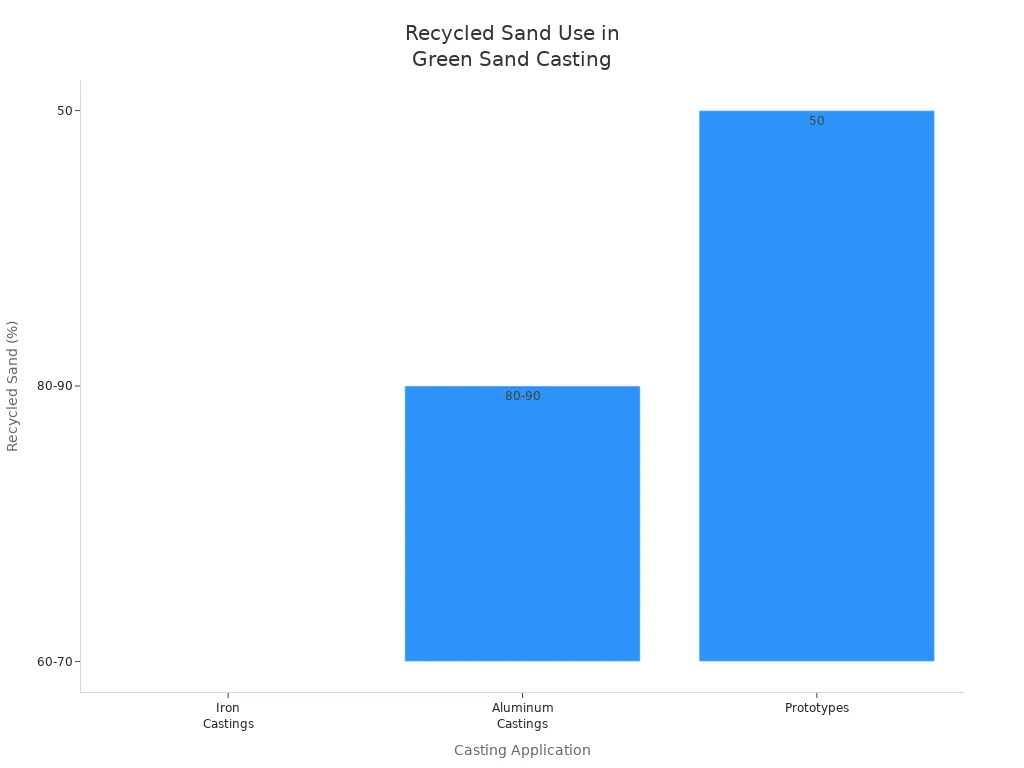

You can use the same sand many times in green sand casting. This saves money and helps nature. Green sand casting equipment lets you recycle sand for many uses. Most foundries mix old sand with new sand to keep quality good. They often use about 70% recycled sand and 30% new sand. Adding new bentonite and checking moisture keeps the sand strong.

You can use the same sand for 5 to 10 times. Good green sand casting equipment with reclamation systems helps you need less new sand. Mechanical attrition removes old clay from sand grains. This makes it easier for small and medium foundries to reuse sand. It keeps costs low and is better for the earth.

Tip: Always test your sand and add new materials when needed. This keeps your castings strong and lowers mistakes.

Environmental Impact

Recycling sand in your foundry helps the earth. Most sand does not get ruined by heat. Only about 15% of the sand mold gets changed by hot metal. You can reuse most of the sand and throw away less.

Used foundry sand is safe for the environment. You can use it for road base, backfill, trenches, or as cover in landfills.

Some foundries, like State Line, recycle about 95% of their green sand. They only buy about 5% new sand.

Recycling sand has helped some foundries cut sand deliveries from eight trucks a week to just two.

When sand cannot be used for casting anymore, you can use it as fill for old quarries or as liners in landfills. This keeps it out of dumps and saves natural resources.

Green sand casting equipment with good reclamation features helps you follow environmental rules and lower your impact. Cleaner ways of working and better waste gas treatment also cut pollution. You can make your foundry greener by reusing sand and improving your process.

Note: By using green sand casting equipment and recycling sand, you help save natural resources and make less landfill waste. This helps make manufacturing cleaner and better for the future.

When you pick green sand casting, you get many benefits.

You spend less money because you can use sand again.

You can make parts in many shapes and sizes. This helps lots of businesses.

You make less waste and use less energy. This is better for the earth.

You follow tough environmental rules and help keep the planet clean.

Green sand casting equipment helps you make good parts and protect nature. You should think about using this method for your next job or ask experts if you want to know more.

FAQ

What is green sand casting equipment?

Green sand casting equipment has machines and tools. These help you mix sand and shape molds. They also help you pour metal. You use this equipment to make metal parts fast and safe. It works for small jobs and big jobs.

How does green sand casting equipment help the environment?

You can use the same sand many times. This means you make less waste. You also save natural resources. New machines use less energy. They help you recycle materials. This makes your foundry better for the earth.

Can you use green sand casting equipment for different metals?

Yes, you can use it for many metals. You can cast iron, steel, aluminum, and bronze. This lets you make parts for many industries. Some examples are cars, ships, and buildings.

How often should you maintain green sand casting equipment?

You should check your equipment every week. Clean mixers often and look at moving parts. Regular care keeps your machines working well. This helps you stop problems before they happen.

What safety tips should you follow when using green sand casting equipment?

Always wear gloves, goggles, and protective clothes.

Keep your work area neat and tidy.

Follow all safety rules in the manual.

Never touch hot metal or moving parts.

Ask someone for help if you are not sure.